Crystallization treatment device based on industrial wastewater discharge reduction

A technology for crystallization treatment and industrial wastewater, which is applied in water/sewage treatment, natural water treatment, water treatment parameter control, etc. It can solve the problems of low automation level, low intelligence, and easy existence of slag inclusion and slag inclusion. Achieve the effect of reducing protective installation measures, reducing production costs, and strong anti-electromagnetic interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

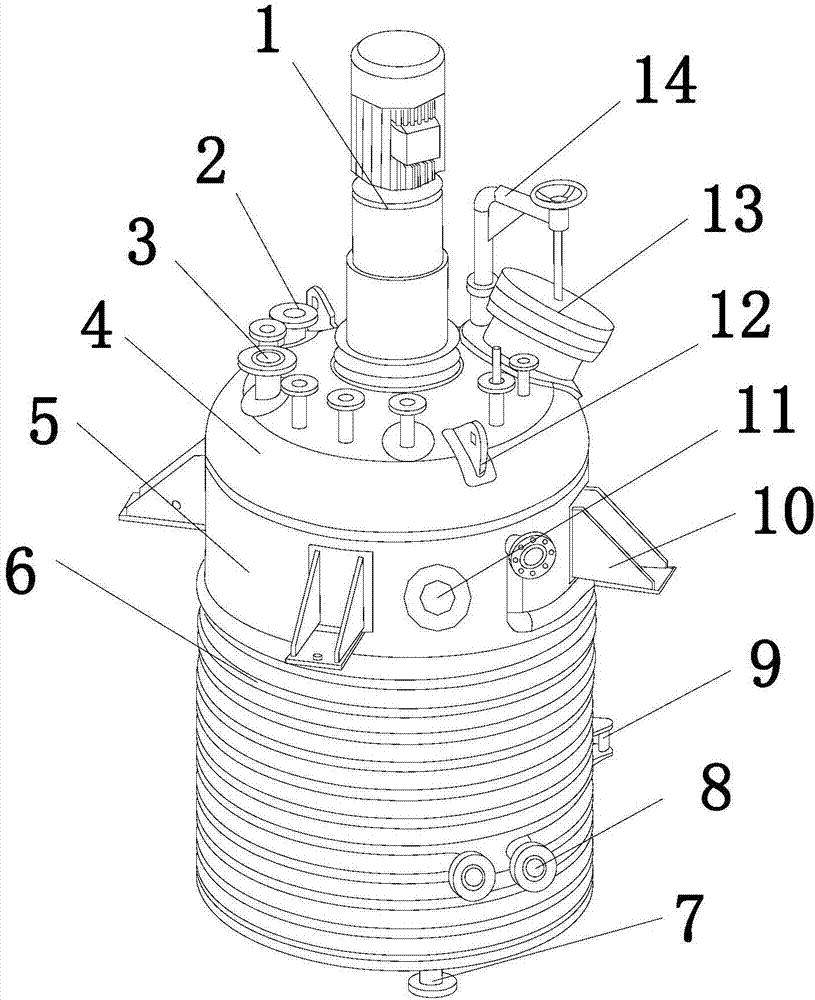

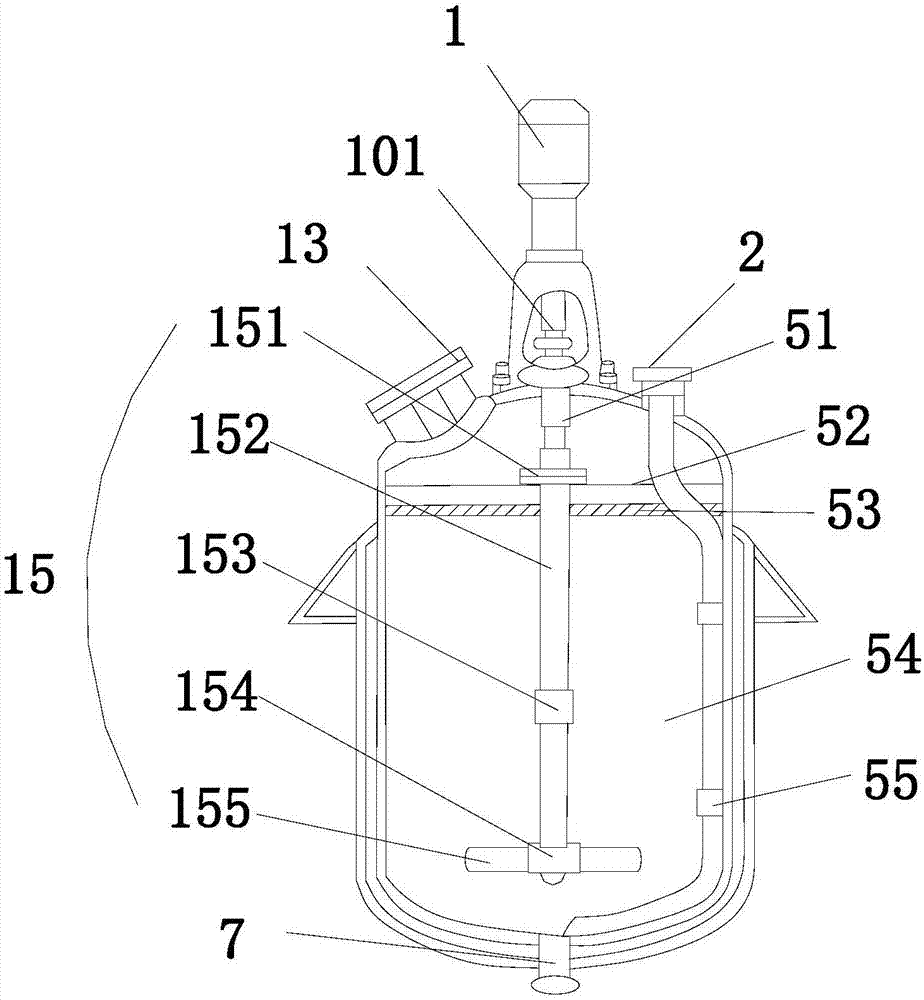

[0035] see Figure 1-Figure 10 , the present invention provides a crystallization treatment device based on industrial wastewater discharge reduction, its structure includes a motor 1, a steam connection 2, a process connection 3, a cylinder cover 4, a cylinder 5, a coil 6, an elutriation column 7, and a water outlet 8 , fixed valve 9, drug inlet 10, manhole 11, lifting lug 12, waste water inlet 13, drainage pipe 14, agitator 15, liquid level signal conversion module 16, programmable controller 17, upper computer 18, driver 19, all The cylinder body 5 is a vertical cylindrical structure and the outer surface is surrounded by a coiled pipe 6, and more than two medicament inlets 10 are installed between the coiled pipe 6 and the cylinder cover 4, and the cylinder cover 4 and the cylinder body The upper port of 5 is clearance fit, and the upper end surface of the cylinder cover 4 is respectively equipped with two or more process connecting pipes 3 evenly and equidistantly. The mo...

Embodiment 2

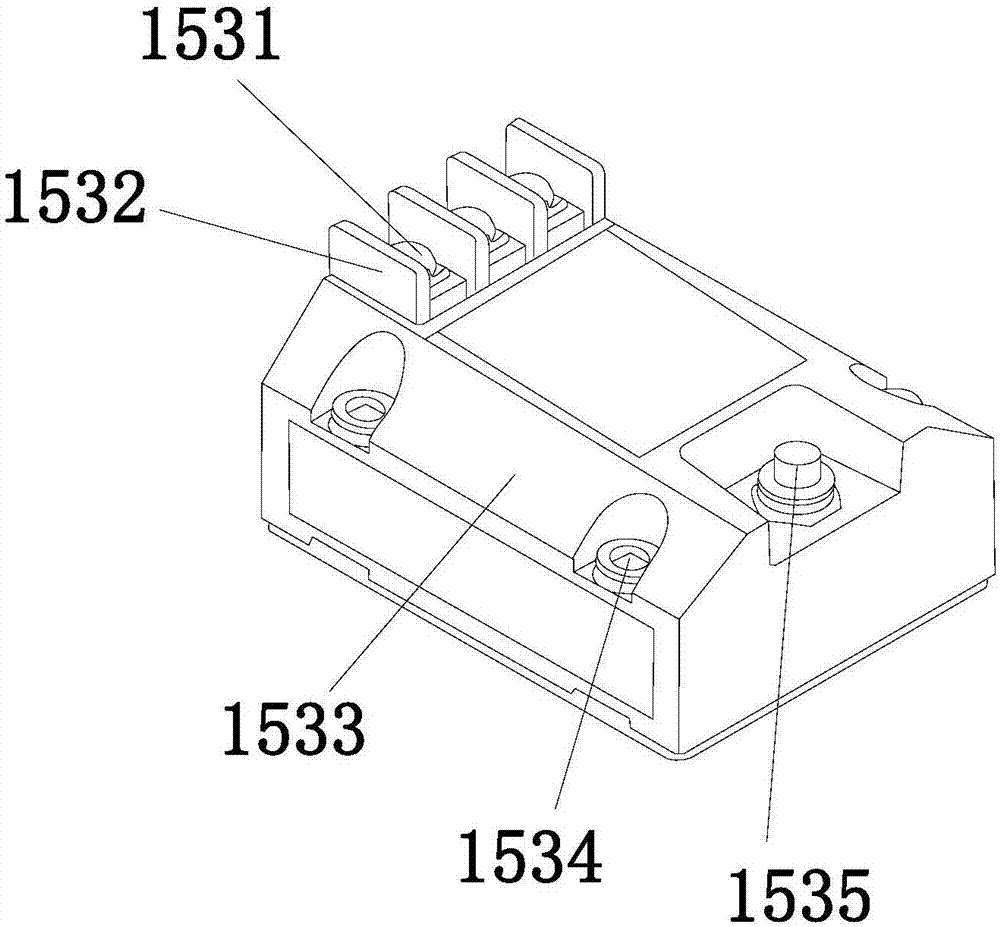

[0038] see Figure 1-Figure 11 , the inside of the heating plate 53 is equipped with an electric heating belt structure, and the electric heating belt structure is composed of a sheath layer 531, a shielding layer 532, an insulating layer 533, a conductive plastic layer 534, and a copper core wire 535. The sheath layer 531 A shielding layer 532 is installed between the insulating layer 533, the shielding layer 532 is arranged inside the sheath layer 531, and the right end of the insulating layer 533 is thermally connected with the conductive plastic layer 534, and the conductive plastic layer 534 Copper core wires 535 are installed on both sides of the right end of the cable, and the sheath layer 531 and insulating layer 533 can be made of modified polyolefin, flame-retardant polyolefin, fluorine-containing polyolefin, or perfluorinated materials.

[0039] In the crystallization chamber, the installed heating plate 53 is equipped with an electric heating belt structure. The el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com