Bottom sludge coagulating reduction as well as preparation method and application thereof

A reducer and sediment technology, applied in dehydration/drying/concentrated sludge treatment, etc., can solve the problems of difficult transportation and disposal of sediment, low efficiency of mud-water separation, and difficulty in taking care of water bodies, etc., to enhance the self-purification ability of water bodies , The system has strong anti-disturbance and takes into account the effect of pollutant removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

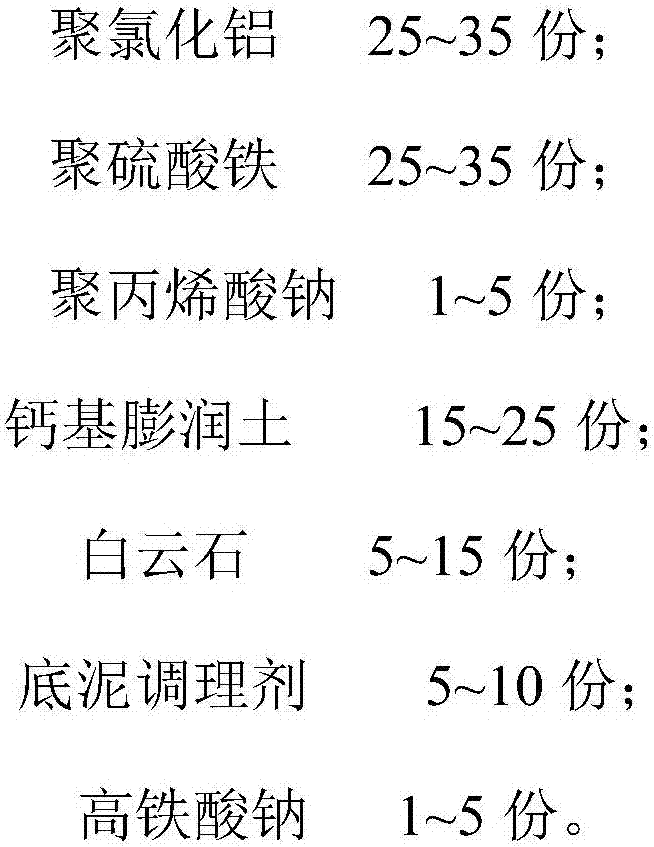

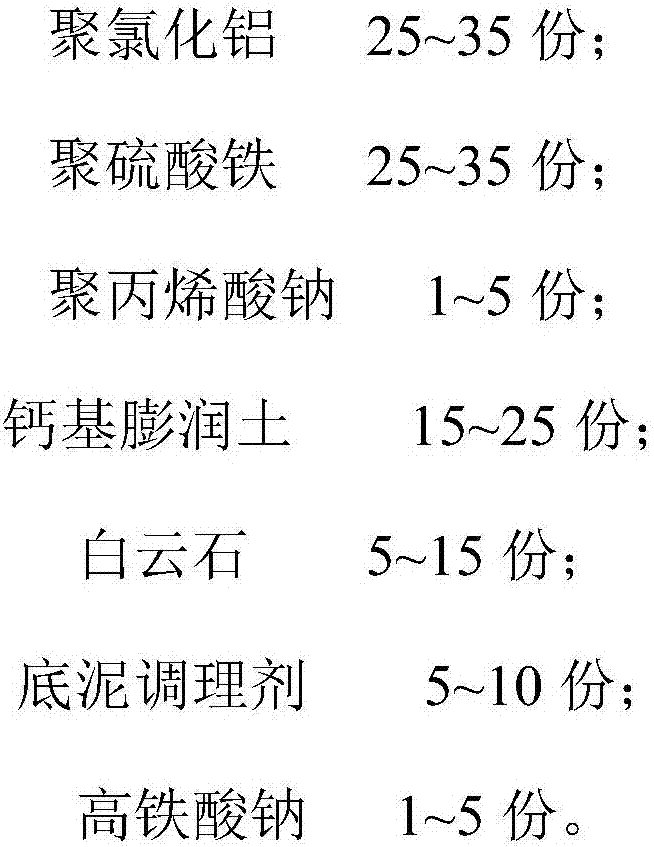

[0028] A sediment coagulation reducer, comprising the following raw materials in parts by weight: 32 parts of 60-mesh polyaluminum chloride, whose effective matter content is ≥ 26%; 26 parts of 60-mesh polyferric sulfate, whose effective matter content is ≥ 20%; molecular weight ≥ 1 part of 12 million 60-mesh sodium polyacrylate; 20 parts of 200-mesh calcium-based bentonite, whose montmorillonite content is ≥ 85%; 13 parts of 200-mesh dolomite; 6 parts of 200-mesh bottom mud conditioner, the bottom mud conditioner It is a product of Gefeng Environmental Protection Technology Co., Ltd. -MSX01-P200; 2 parts of 60 mesh sodium ferrate. The preparation method is as follows: uniformly mix the above-mentioned raw materials with a dry powder mixer to obtain the sediment coagulation reducer.

[0029] According to the beaker experiment, the black and smelly water in the black and smelly river course was mixed with the bottom mud at a ratio of 1L:100g to obtain a mixed mud-water system...

Embodiment 2

[0032] A sediment coagulation reducer, comprising the following raw materials in parts by weight: 25 parts of 40-mesh polyaluminum chloride, whose effective content is ≥ 26%; 35 parts of 40-mesh polyferric sulfate, whose effective content is ≥ 20%; molecular weight ≥ 3 parts of 12 million 40-mesh sodium polyacrylate, 16 parts of 200-mesh calcium-based bentonite, its montmorillonite content ≥ 85%; 10 parts of 200-mesh dolomite; 8 parts of 200-mesh bottom mud conditioner, the bottom mud conditioner It is a product of Gefeng Environmental Protection Technology Co., Ltd. -MSX01-P200; 3 parts of 40 mesh sodium ferrate. The preparation method is as follows: uniformly mix the above-mentioned raw materials with a dry powder mixer to obtain the sediment coagulation reducer.

[0033] According to the beaker experiment, the black and smelly water in the black and smelly river course was mixed with the bottom mud at a ratio of 1L:100g to obtain a mixed mud-water system. The bottom mud w...

Embodiment 3

[0036] A sediment coagulation reducer, comprising the following raw materials in parts by weight: 34 parts of 80-mesh polyaluminum chloride, whose effective matter content is ≥ 26%; 26 parts of 80-mesh polyferric sulfate, whose effective matter content is ≥ 20%; molecular weight ≥ 5 parts of 12 million 80-mesh sodium polyacrylate, 22 parts of 200-mesh calcium-based bentonite, its montmorillonite content ≥ 85%; 6 parts of 200-mesh dolomite; 5 parts of 200-mesh bottom mud conditioner, the bottom mud conditioner It is a product of Gefeng Environmental Protection Technology Co., Ltd. -MSX01-P200; 2 parts of 80 mesh sodium ferrate. The preparation method is as follows: uniformly mixing the above-mentioned raw materials in the formula amount through a dry powder mixer to obtain the sediment coagulation reducer.

[0037] According to the beaker experiment, the black and smelly water in the black and smelly river course was mixed with the bottom mud at a ratio of 1L:100g to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com