A manganese doped cspbbr 3 Perovskite quantum dot and molecular sieve composite luminescent material and its preparation method and application

A technology of luminescent materials and molecular sieves, applied in luminescent materials, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve problems such as harmfulness to human body and environment, limit further application, toxicity, etc., and achieve good application prospects , good environmental stability, and the effect of reducing the proportion of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

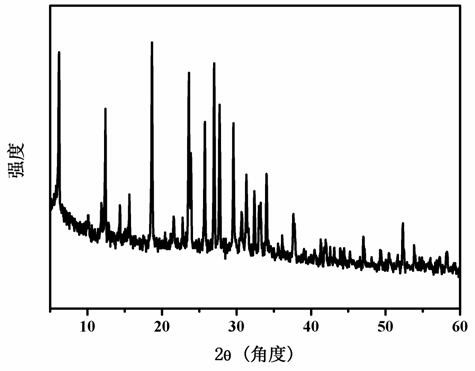

[0037] A manganese-doped CsPbBr 3 The preparation method of the perovskite quantum dot and molecular sieve composite luminescent material specifically comprises the following steps:

[0038] (1) Accurately weigh 2.13g cesium bromide (CsBr), dissolve it in 10mL distilled water to obtain a 1mol / L cesium bromide solution; mix 1.0g Y-type molecular sieve (SiO 2 / Al 2 o 3 = 5.1, Alfa Aesar brand) into cesium bromide solution, stirred in a water bath at 60°C for 20h (stirring speed is 400r / min), centrifuged (centrifugal speed is 3500r / min) for 5min, the lower layer sample was taken, washed twice with distilled water, And after drying at 60°C for 12h, Cs was obtained + Exchanged Y-type molecular sieve;

[0039] (2) Add 5 mL of octadecene (ODE), 1 mL of oleic acid (OA), 1 mL of oleylamine (OAm), lead bromide (PbBr) 2 ) 0.012g (0.033mmol), manganese bromide (MnBr 2 ) 0.035g (0.167mmol) was mixed in a container, vacuumed at 120°C for 30min, N 2 Stir at 120°C under the atmosphere...

Embodiment 2

[0043] A manganese-doped CsPbBr 3 The preparation method of the perovskite quantum dot and molecular sieve composite luminescent material specifically comprises the following steps:

[0044] (1) Accurately weigh 0.213g cesium bromide (CsBr), dissolve it in 10mL distilled water to obtain a 0.1mol / L cesium bromide solution; mix 1.0g Y-type molecular sieve (SiO 2 / Al 2 o 3 = 5.1, Alfa Aesar brand) into cesium bromide solution, stirred in a water bath at 80°C for 20h (stirring speed is 400r / min), centrifuged (centrifugal speed is 3500r / min) for 5min, took the lower layer sample, washed twice with distilled water, And after drying at 80°C for 12h, Cs was obtained + Exchanged Y-type molecular sieve;

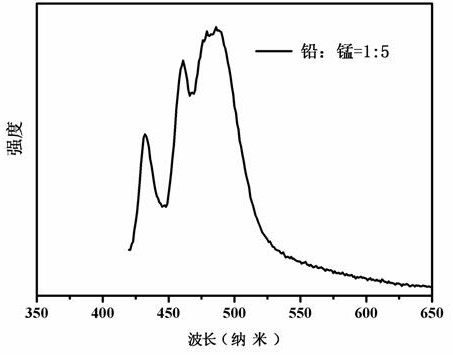

[0045] (2) Add 5 mL of octadecene (ODE), 1 mL of oleic acid (OA), 1 mL of oleylamine (OAm), lead bromide (PbBr) 2 ) 0.018g (0.05mmol), manganese bromide (MnBr 2 ) 0.032g (0.15mmol) mixed in a container, vacuumed at 100°C for 30min, N 2 Stir at 120°C under the atmosphere (stirri...

Embodiment 3

[0049] A manganese-doped CsPbBr 3 The preparation method of the perovskite quantum dot and molecular sieve composite luminescent material specifically comprises the following steps:

[0050] (1) Accurately weigh 1.065g cesium bromide (CsBr), dissolve it in 10mL distilled water to obtain a 0.5mol / L cesium bromide solution; mix 1.0g Y-type molecular sieve (SiO 2 / Al 2 o 3 = 5.1, Alfa Aesar brand) into the cesium bromide solution, stirred in a water bath at 25°C for 36h (the stirring speed was 400r / min), centrifuged (the centrifugation speed was 3500r / min) for 5min, the lower layer sample was taken, washed twice with distilled water, And after drying at 120°C for 5h, Cs was obtained + Exchanged Y-type molecular sieve;

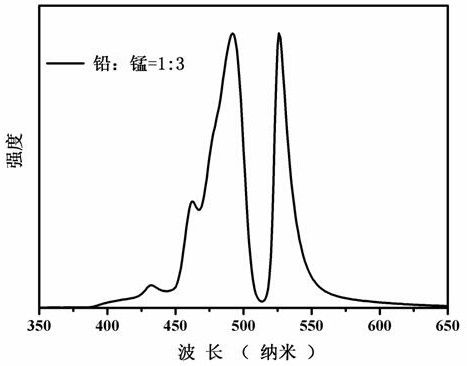

[0051] (2) Add 5 mL of octadecene (ODE), 1 mL of oleic acid (OA), 1 mL of oleylamine (OAm), lead bromide (PbBr) 2 ) 0.037g (0.1mmol), manganese bromide (MnBr 2 ) 0.022g (0.1mmol) mixed in the container, vacuumed at 120°C for 30min, N 2 Stir at 150°C under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com