Method for synthesizing 5'-O-ethylene hexanedioyl-5-floxuridine on line through catalyzing of lipase

A technology of fluorouridine and lipase, which is applied in the field of lipase-catalyzed online synthesis of 5'-O-ethylene adipyl-5-fluorouridine, which can solve the problems of low conversion rate and selectivity, long reaction time, etc. , achieve the effects of shortening the reaction time, reducing the reaction cost, high conversion rate and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

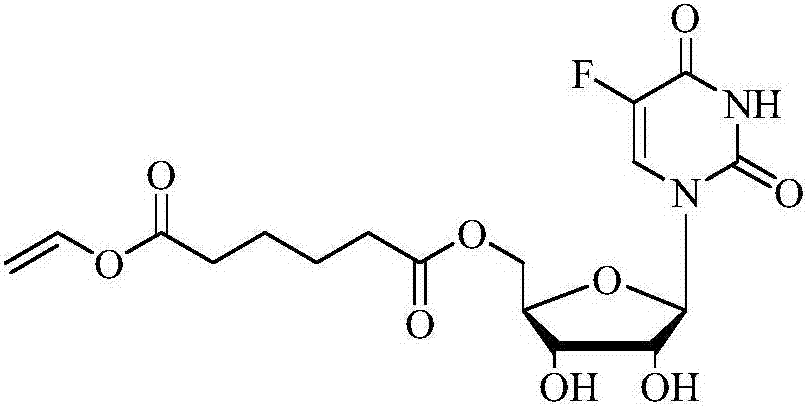

[0025] Example 1: Synthesis of 5'-O-ethylene adipyl-5-fluorouridine

[0026]

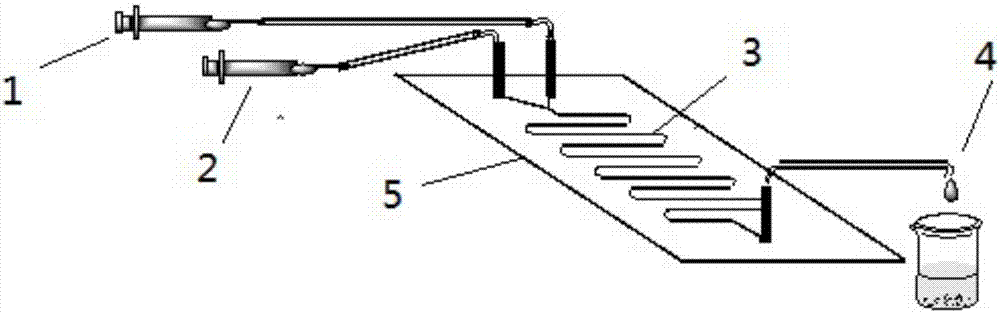

[0027] device reference figure 1 : Dissolve 5-fluorouridine (1.0mmol) in 1.33mL DMSO and 8.67mL of tert-amyl alcohol, dissolve divinyl adipate (9.0mmol) in 10mL of tert-amyl alcohol, and then put them in 10mL syringes for later use . 0.87g of lipase Lipozyme TLIM was evenly filled in the reaction channel, and driven by the PD 1200 syringe pump, the two reaction solutions were separated at 10.4 μL min -1 The flow rate enters the reaction channel through the "Y" joint for reaction, and the temperature of the reactor is controlled at 30°C by a water bath thermostat. The reaction solution flows continuously in the reaction channel for 30 minutes, and the reaction results are tracked and detected by thin-layer chromatography (TLC).

[0028] Collect the reaction solution online by the product collector, remove the solvent by distillation under reduced pressure, use 200-300 mesh silica gel wet packing...

Embodiment 2-6

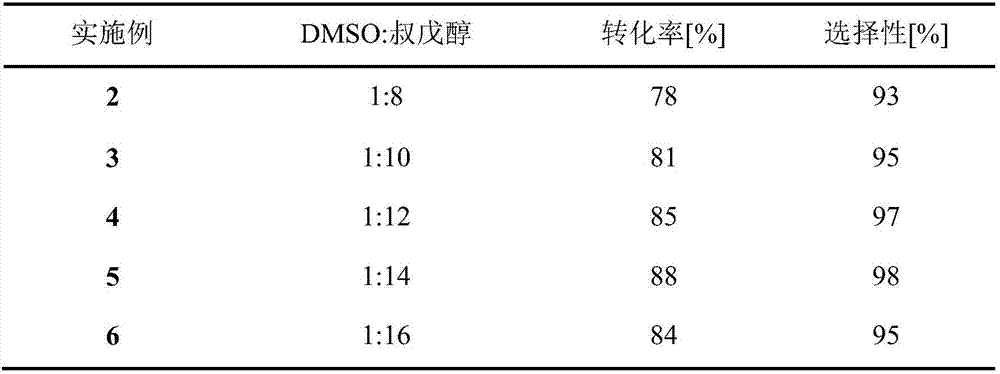

[0033] Change the volume ratio of DMSO and tert-amyl alcohol in the reaction solvent, control the temperature to be 50°C, and the others are the same as in Example 1. The reaction results are shown in Table 1:

[0034] Table 1: Influence of the volume ratio of DMSO and tert-amyl alcohol on the reaction in the reaction solvent

[0035]

[0036] The results in Table 1 show that when the flow rate is 10.4 μL min -1 , the reaction time is 30min, the reaction temperature is 50°C, the molar ratio of reactant 5-fluorouridine to divinyl adipate is 1:9, and the concentration of 5-fluorouridine in the reaction system is 0.05mmol / mL, the conversion rate increases with the increase of the organic solvent volume ratio in the reactor, and reaches the optimum when the volume ratio of DMSO and tert-amyl alcohol reaches 1:14, and continuing to increase the volume ratio will result in incomplete dissolution of the reactant and lower conversion rates. Therefore, the optimum volume ratio of...

Embodiment 7-11

[0038] The substrate molar ratio of 5-fluorouridine and divinyl adipate in the microfluidic microchannel reactor was changed, and the temperature was controlled at 50°C. Others were the same as in Example 1. The results are shown in Table 2:

[0039] Table 2: Effect of 5-fluorouridine and divinyl adipate substrate molar ratio on reaction

[0040]

[0041] The results in Table 2 show that when the flow rate is 10.4 μL min -1 , the reaction time is 30min, the reaction temperature is 50°C, the volume ratio of DMSO to tert-amyl alcohol in the reaction solvent is 1:14, and the concentration of 5-fluorouridine in the reaction system is 0.05mmol / mL. With the increase of divinyl adipate, the conversion rate of reaction also increases, and when the substrate molar ratio was 1:9, the conversion rate of reaction reached the best, so in the microfluidic microchannel reactor of the present invention, the most The molar ratio of the best substrate 5-fluorouridine to divinyl adipate is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com