A tile prefabricated thermal insulation pipeline with a moisture-proof device

A technology of tile and moisture-proof coating, applied in the direction of protecting pipelines through thermal insulation, thermal insulation, pipeline protection, etc., can solve the problems of corrosion of working pipes, affecting liquid transportation, pipeline leakage, etc., to enhance flexibility and anti-aging properties, The effect of avoiding moisture rust and strong anti-aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

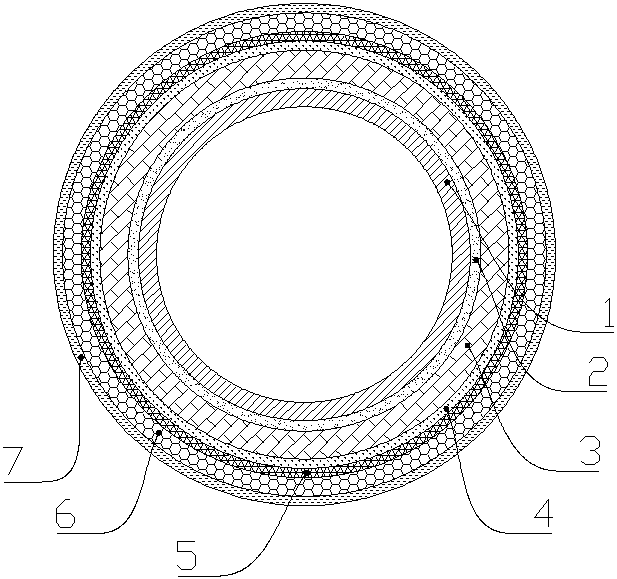

[0025] Such as figure 1 A tile prefabricated thermal insulation pipeline with a moisture-proof device is shown, including a working tube layer, a thermal insulation layer, a moisture-proof layer and an outer sheath layer; the working tube layer is a working steel pipe 1; the thermal insulation layer is a calcium silicate tile 2; the moisture-proof layer includes a waterproof cold rubber layer 3, an aluminum foil tape layer 4, and a graphene moisture-proof coating 5, and the waterproof cold rubber layer 3 is directly coated on the outer surface of the working steel pipe 1, and the aluminum foil The tape layer 4 is wound on the outer surface of the calcium silicate tile 2, and the graphene moisture-proof coating 5 is coated on the outer surface of the aluminum foil tape layer 4, and the calcium silicate tile 2 is fixedly wound and used as heat preservation The calcium silicate tiles 2 of the first layer are protected against moisture; the outer sheath layer is an iron layer 6, a...

Embodiment 2

[0034] Such as figure 1 A tile prefabricated thermal insulation pipeline with a moisture-proof device is shown, including a working tube layer, a thermal insulation layer, a moisture-proof layer and an outer sheath layer; the working tube layer is a working steel pipe 1; the thermal insulation layer is a calcium silicate tile 2; the moisture-proof layer includes a waterproof cold rubber layer 3, an aluminum foil tape layer 4, and a graphene moisture-proof coating 5, and the waterproof cold rubber layer 3 is directly coated on the outer surface of the working steel pipe 1, and the aluminum foil The tape layer 4 is wound on the outer surface of the calcium silicate tile 2, and the graphene moisture-proof coating 5 is coated on the outer surface of the aluminum foil tape layer 4; the outer sheath layer is an iron layer (6), and the The outer surface of the iron skin layer (6) is coated with an anti-corrosion paint layer (7).

[0035] The manufacturing method of the tile prefabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com