Composite electrode and preparation method thereof, and heterojunction solar cell and preparation method thereof

A technology of solar cells and composite electrodes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem that the photoelectric conversion efficiency needs to be further improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

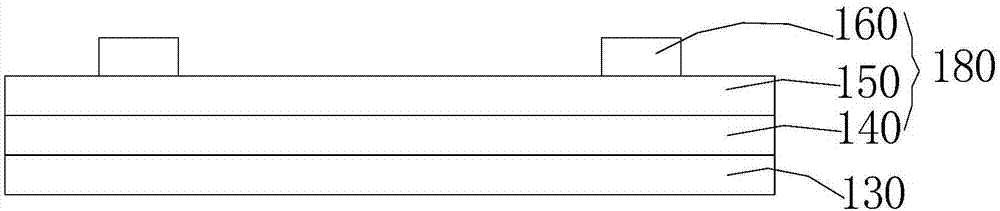

[0076] A method for preparing a compound electrode structure of a heterojunction solar cell, comprising the steps of:

[0077] An interface buffer layer is formed on the doped amorphous silicon layer; when the doped amorphous silicon layer is P-type, the work function of the interface buffer layer is greater than or equal to 5V; when the doped amorphous silicon layer is N-type, the interface buffer layer The work function is less than or equal to 4.2eV;

[0078] forming a transparent conductive layer on the interface buffer layer;

[0079] Electrodes are formed on the transparent conductive layer.

[0080] Preferably, when the doped amorphous silicon layer is P-type, the interface buffer layer is formed by physical vapor deposition. For example, vacuum evaporation or sputter evaporation formation.

[0081] Preferably, when the interface buffer layer is lithium fluoride or cesium fluoride, the interface buffer layer is deposited by vacuum evaporation. When the interface buf...

Embodiment 1

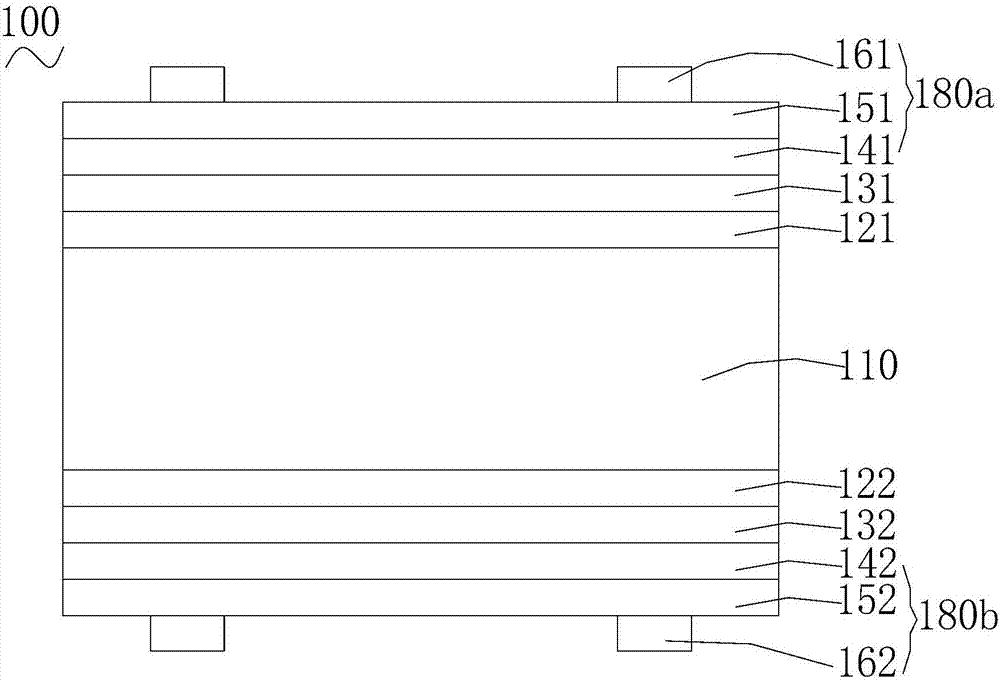

[0090] The N-type crystalline silicon wafer is passed through an alkaline solution to remove the damaged layer; the N-type crystalline silicon wafer is cleaned and textured, and the surface phosphosilicate glass is removed.

[0091] On one surface of the N-type crystalline silicon wafer, the intrinsic hydrogenated amorphous silicon film (i-a-Si:H) and the N-type hydrogenated amorphous silicon film (n-a-Si:H) are deposited by PECVD to form the second intrinsic layer and a second doped amorphous silicon layer.

[0092] On the other surface of the N-type crystalline silicon wafer, the intrinsic hydrogenated amorphous silicon film (i-a-Si:H) and the P-type hydrogenated amorphous silicon film (p-a-Si:H) were deposited by PECVD to form the first intrinsic layer and the first doped amorphous silicon layer.

[0093] Non-stoichiometric molybdenum oxide is grown on the first doped amorphous silicon layer by vacuum evaporation with a thickness of 6 nm.

[0094] Reactive plasma depositi...

Embodiment 2

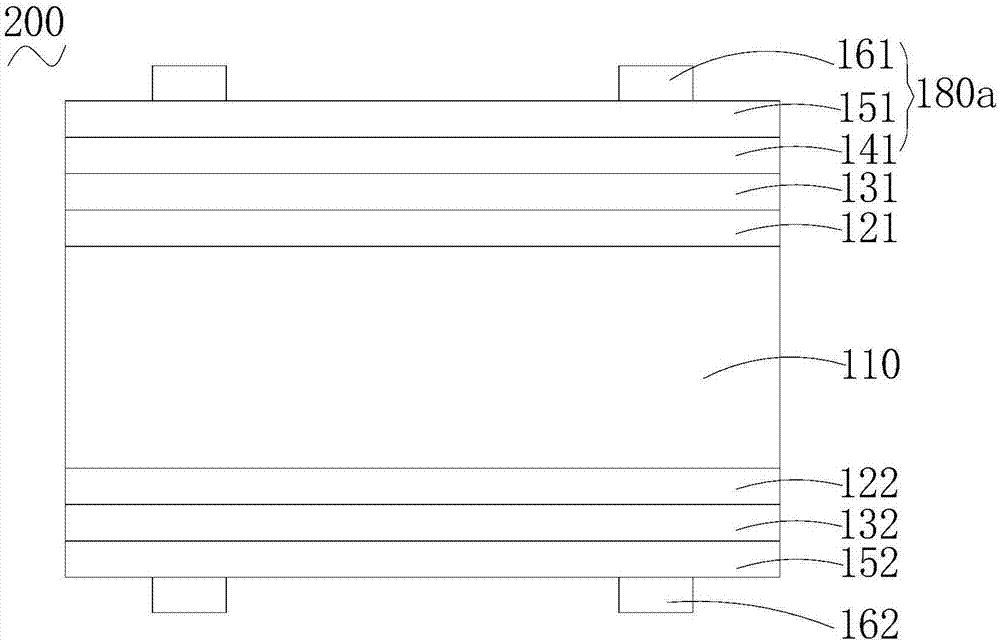

[0098] The N-type crystalline silicon wafer is passed through an alkaline solution to remove the damaged layer; the N-type crystalline silicon wafer is cleaned and textured, and the surface phosphosilicate glass is removed.

[0099] On one surface of the N-type crystalline silicon wafer, the intrinsic hydrogenated amorphous silicon film (i-a-Si:H) and the N-type hydrogenated amorphous silicon film (n-a-Si:H) are deposited by PECVD to form the second intrinsic layer and a second doped amorphous silicon layer.

[0100] On the other surface of the N-type crystalline silicon wafer, the intrinsic hydrogenated amorphous silicon film (i-a-Si:H) and the P-type hydrogenated amorphous silicon film (p-a-Si:H) were deposited by PECVD to form the first intrinsic layer and the first doped amorphous silicon layer.

[0101] Non-stoichiometric molybdenum oxide is grown on the first doped amorphous silicon layer by vacuum evaporation with a thickness of 6 nm.

[0102] Non-stoichiometric titan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Work function | aaaaa | aaaaa |

| Work function | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com