Finished potato protein as well as processing technique and processing equipment for finished potato protein

A processing technology and finished product technology, which is applied in the field of nutrition and health products preparation, can solve the problems of raw material cost and transportation cost loss, cumbersome production process, and other sweet potato rot, and achieve the effect of avoiding deterioration loss, reducing transportation process, and good health care effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

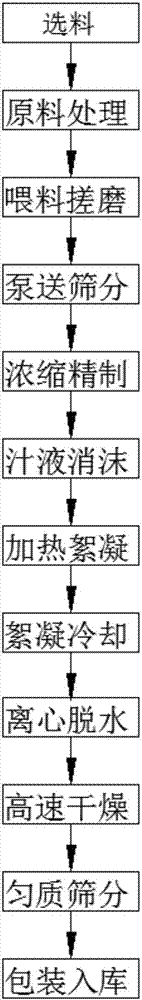

[0045] see figure 1 , a processing technology of potato finished protein, comprising the steps of:

[0046] The present invention realizes in this way, a kind of processing technology of potato product protein, comprises the following steps:

[0047] S1: material selection

[0048] Take fresh raw potato as raw material;

[0049] S2: Raw material handling

[0050] Remove the mud and stone from the raw materials and clean them.

[0051] S3: Feeding and rubbing

[0052] After the processed raw materials are evenly fed, they are rubbed and ground.

[0053] S4: Pumping and screening

[0054] The rubbed raw potatoes are pumped to the sieving equipment for sieving treatment, the lumps are removed, and the sieved raw potato juice is obtained.

[0055] S5: concentrated and refined

[0056] Concentrate and refine the sieved raw potato juice to remove part of the water and unwanted components.

[0057] S6: juice defoaming

[0058] The concentrated and refined raw potato juice is ...

Embodiment 2

[0074] see figure 1 , a processing technology of potato finished protein, comprising the steps of:

[0075] The present invention realizes in this way, a kind of processing technology of potato product protein, comprises the following steps:

[0076] S1: material selection

[0077] Take fresh raw potato as raw material;

[0078] S2: Raw material handling

[0079] Remove the mud and stone from the raw materials and clean them.

[0080] S3: Feeding and rubbing

[0081] After the processed raw materials are evenly fed, they are rubbed and ground.

[0082] S4: Pumping and screening

[0083] The rubbed raw potatoes are pumped to the sieving equipment for sieving treatment, the lumps are removed, and the sieved raw potato juice is obtained.

[0084] S5: concentrated and refined

[0085] Concentrate and refine the sieved raw potato juice to remove part of the water and unwanted components.

[0086] S6: juice defoaming

[0087] The concentrated and refined raw potato juice i...

Embodiment 3

[0103] see figure 1 , a processing technology of potato finished protein, comprising the steps of:

[0104] The present invention realizes in this way, a kind of processing technology of potato product protein, comprises the following steps:

[0105] S1: material selection

[0106] Take fresh raw potato as raw material;

[0107] S2: Raw material handling

[0108] Remove the mud and stone from the raw materials and clean them.

[0109] S3: Feeding and rubbing

[0110] After the processed raw materials are evenly fed, they are rubbed and ground.

[0111] S4: Pumping and screening

[0112] The rubbed raw potatoes are pumped to the sieving equipment for sieving treatment, the lumps are removed, and the sieved raw potato juice is obtained.

[0113] S5: concentrated and refined

[0114] Concentrate and refine the sieved raw potato juice to remove part of the water and unwanted components.

[0115] S6: juice defoaming

[0116] The concentrated and refined raw potato juice i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com