Device and method for preparing nano-material or nano-composite material through quick reacting

A technology of nanocomposite materials and nanomaterials, which is applied in the field of rapid reaction preparation of nanomaterials or nanocomposite materials. It can solve the problems of rapid reaction three-pass and reaction speed mismatch, and adhere to the wall of the device, so as to achieve uniform appearance. , Narrow particle size distribution and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

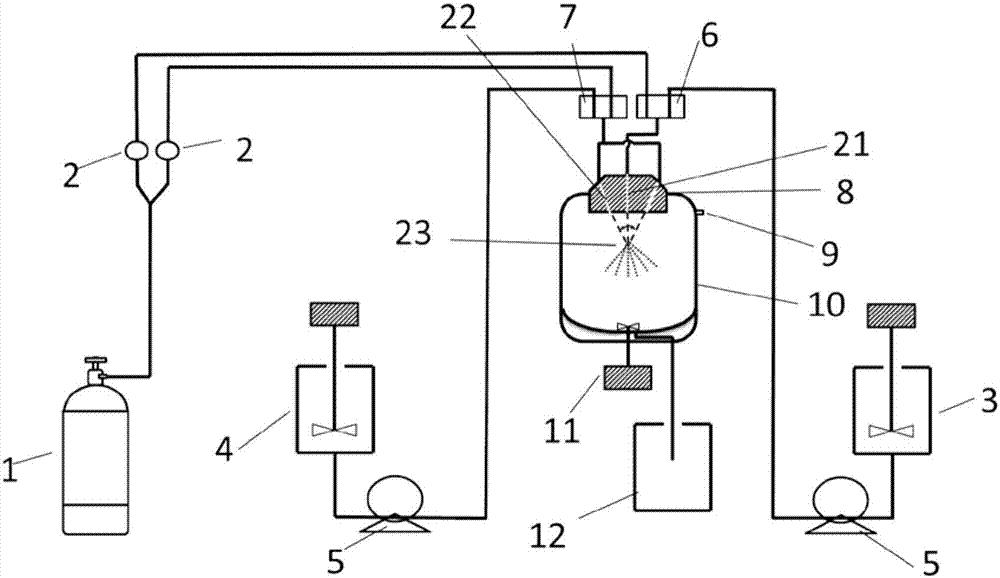

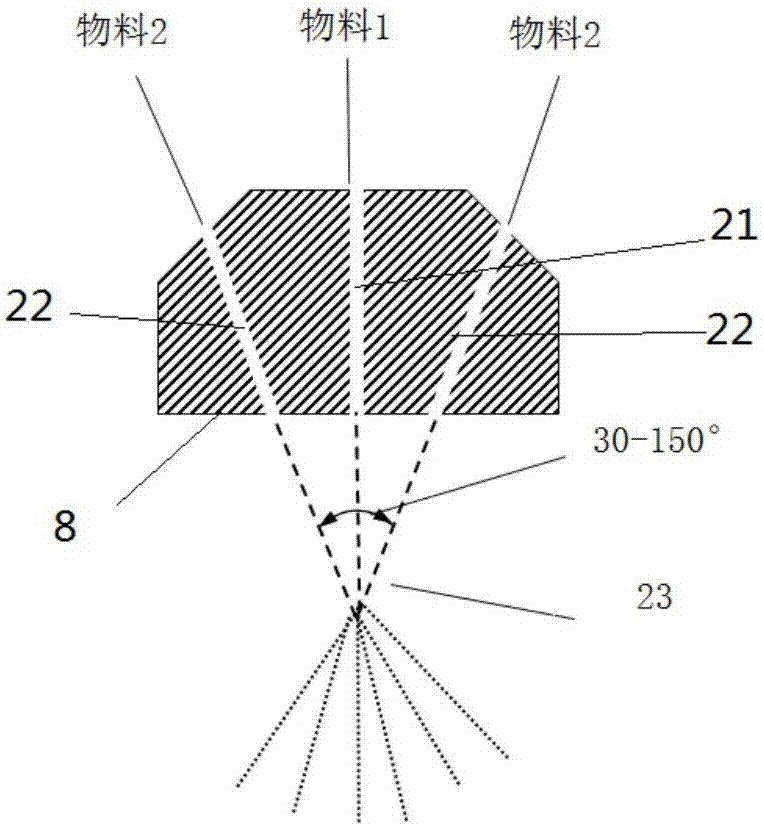

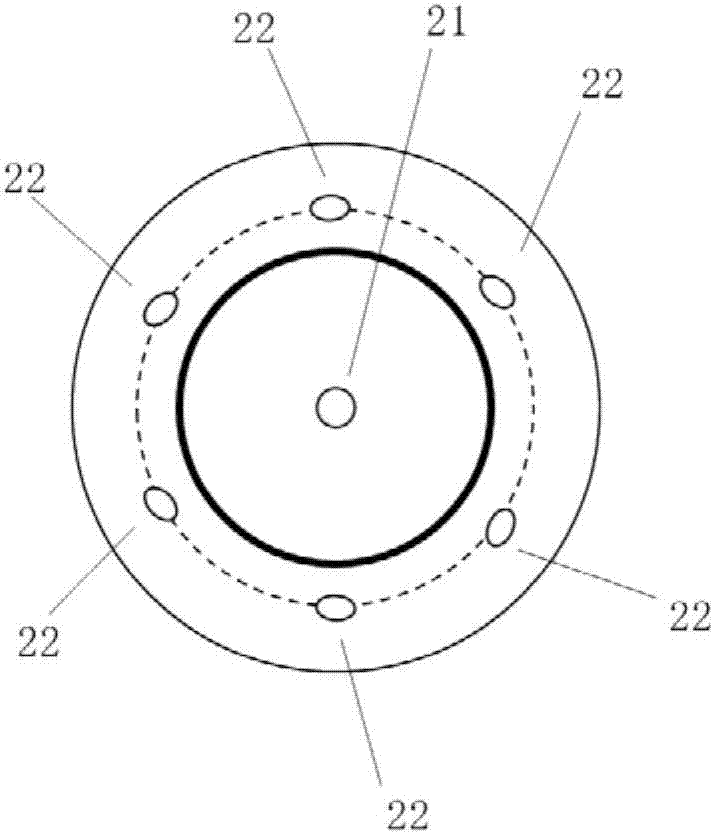

[0046] Such as Figure 1~Figure 2 As shown, a device for rapid reaction preparation of nanomaterials or nanocomposites, which includes a high-pressure inert gas cylinder 1, a gas pressure gauge 2, a raw material stirring tank, a peristaltic pump 5, a pressure storage tank, an impact reactor 8, a temperature control Reaction vessel 10, product storage tank 12, described impact reactor 8 is positioned at the upper opening of temperature control reaction vessel 10; A symmetrical guide channel 22, the angle between the symmetrical guide channels 22 is 30 ~ 150 °, the raw material stirring tank includes the first raw material stirring tank 3 and the second raw material stirring tank 4, the pressure storage The feed tank includes a first pressure storage tank 6 and a second pressure storage tank 7, the first raw material stirring tank 3 is connected with the first pressure storage tank 6 through a peristaltic pump 5, and the second raw material stirring tank 4 is passed through The...

Embodiment 4

[0057] Adopt the continuous reaction system and method that embodiment 1 provides to prepare silver-coated nickel nano-sol, it comprises the following steps:

[0058] Add a certain amount of mixed solution of silver nitrate, hydroxyethyl cellulose and nickel nanoparticles into the first raw material stirring tank 3, pour a certain amount of formaldehyde solution into the second raw material stirring tank 4, and start stirring. The peristaltic pump 5 is turned on, and the liquid in the first raw material stirring tank 3 and the second raw material stirring tank 4 flows into the first pressure storage tank 6 and the second pressure storage tank 7 . Simultaneously open high-pressure inert gas cylinder 1 and make gas enter in the first pressure storage tank 6 and the second pressure storage tank 7, make the liquid pressure in the first pressure storage tank 6 and the second pressure storage tank 7 maintain At 0.35MPa. Before the experiment, the temperature control device of the t...

Embodiment 5

[0061] The continuous reaction system and method provided in Example 1 are used to prepare silver-coated tin oxide rice particle sol, including the following steps:

[0062] Add a certain amount of mixed solution of silver nitrate, sodium citrate and tin oxide nanoparticles into the first raw material stirring tank 3, pour a certain amount of hydrazine hydrate solution into the second raw material stirring tank 4, and start stirring. The peristaltic pump 5 is turned on, and the liquid in the first raw material stirring tank 3 and the second raw material stirring tank 4 flows into the first pressure storage tank 6 and the second pressure storage tank 7 . Simultaneously open high-pressure inert gas cylinder 1 and make gas enter in the first pressure storage tank 6 and the second pressure storage tank 7, make the liquid pressure in the first pressure storage tank 6 and the second pressure storage tank 7 maintain At 0.5MPa. Before the experiment, the temperature control device of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com