Self-cleaning type low-temperature flue gas heat exchanger

A low-temperature flue gas and heat exchanger technology, applied in heat exchange equipment, lighting and heating equipment, coatings, etc., can solve the problems of low enthusiasm for installing flue gas heat exchangers and low investment returns, and achieve anti-fouling Good clogging performance, avoiding corrosion, and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

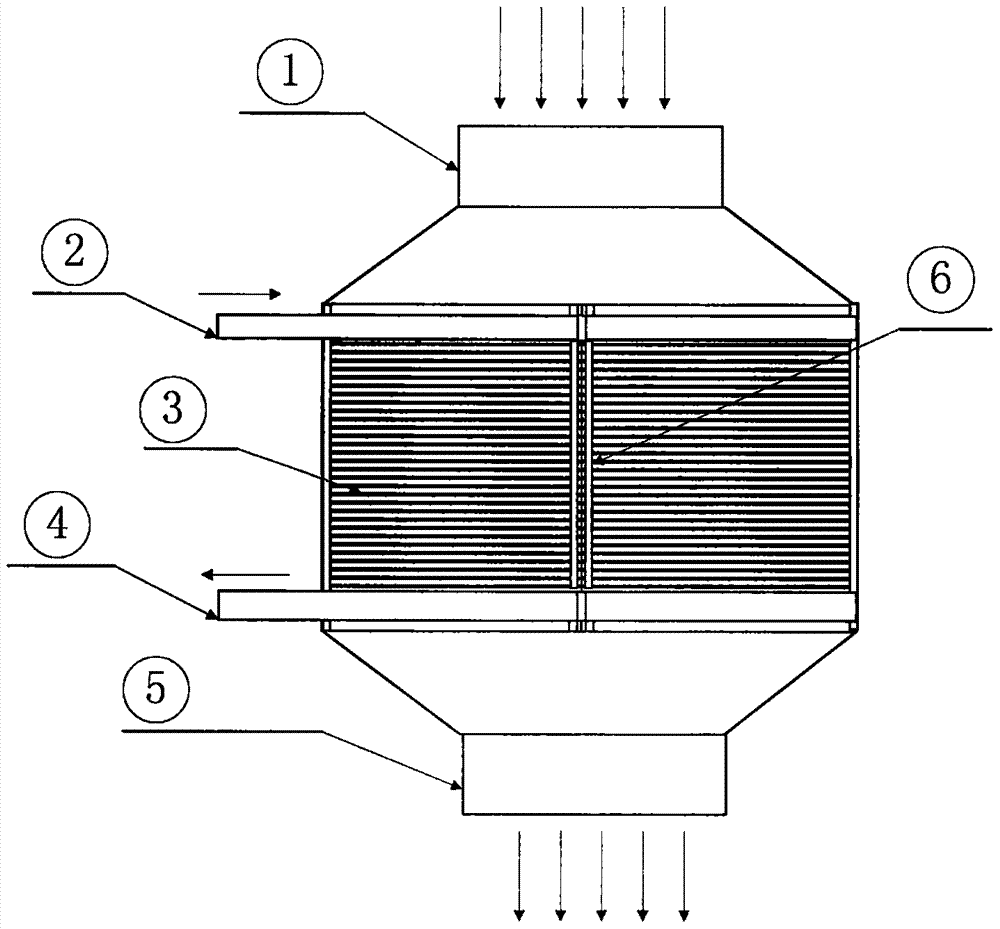

[0011] Such as figure 1 As shown in the self-cleaning low-temperature flue gas heat exchanger device, the low-temperature flue gas of ≤350°C enters through the inlet 1 and travels outside the coiled pipe, while the refrigerant water enters through the water inlet 2, and the flue gas exchanges heat with the refrigerant water. The water is sent out through the outlet 2, and the cooled flue gas is released through the outlet. The coils are held in place by brackets.

[0012] Such as figure 1 As shown, the coil 3 can be a light pipe or can surround fins to increase the contact area, and the surface of the light pipe or the fins is coated with polytetrafluoroethylene material.

[0013] According to the characteristics of PTFE material, such as strong acid and alkali corrosion resistance, high and low temperature resistance, smooth and non-adhesive surface,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com