Integrated proteomic sample pretreatment platform based on SCX (strong cation exchange)/SAX (strong anion exchange) mixed filling material and application thereof

A technology of proteomics and sample pretreatment, which is applied in the direction of scientific instruments, material separation, and analytical materials, etc., which can solve the problems such as greater influence of pH on the effect of enrichment, limited effect of protein enrichment, and limitations of proteomics methods. Achieve the effect of increasing sample capacity, improving reproducibility and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1 Proteomics sample pretreatment platform integrating protein pretreatment

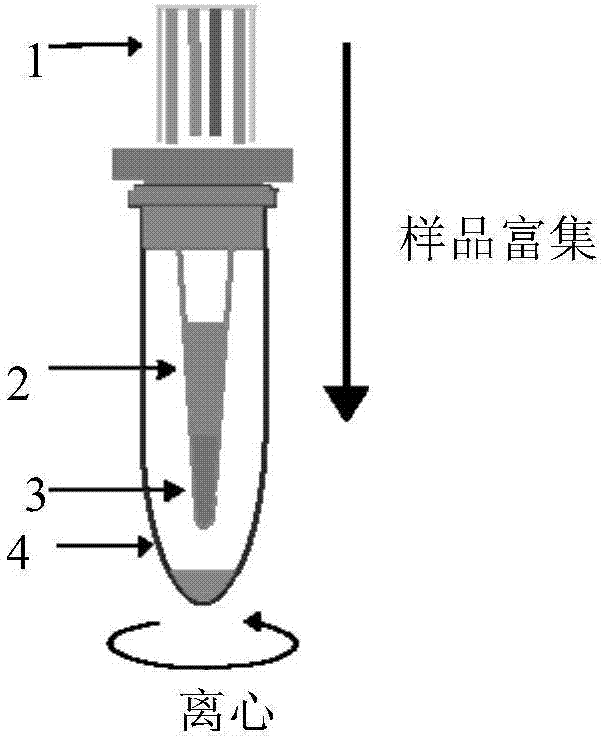

[0048] like figure 1 Shown, a proteomics sample preparation platform with integrated protein preparation, including pipette tip 1, SAX and SCX mixed media 2 and C18 membrane 3. Among them, the pipette tip 1 is a standard 200μL tip, the C18 film 3 is filled at the lower end of the pipette tip 1 with a length of about 3 mm, and the 2mg SAX and SCX mixed filler 2 is filled at the lower end of the pipette tip 1 and C18 on the membrane 3.

[0049] Place the support block on the upper end of the 1.5mL collection tube 4, place the proteomics sample pre-processing platform on the collection tube 4 through the support block, put the collection tube 4 into the centrifuge, and centrifuge the protein solution or reagents. Flow through the proteomics sample pre-processing platform to complete protein pre-enrichment, enzymatic hydrolysis and other operations. The specific steps are as follows:

[...

Embodiment 2

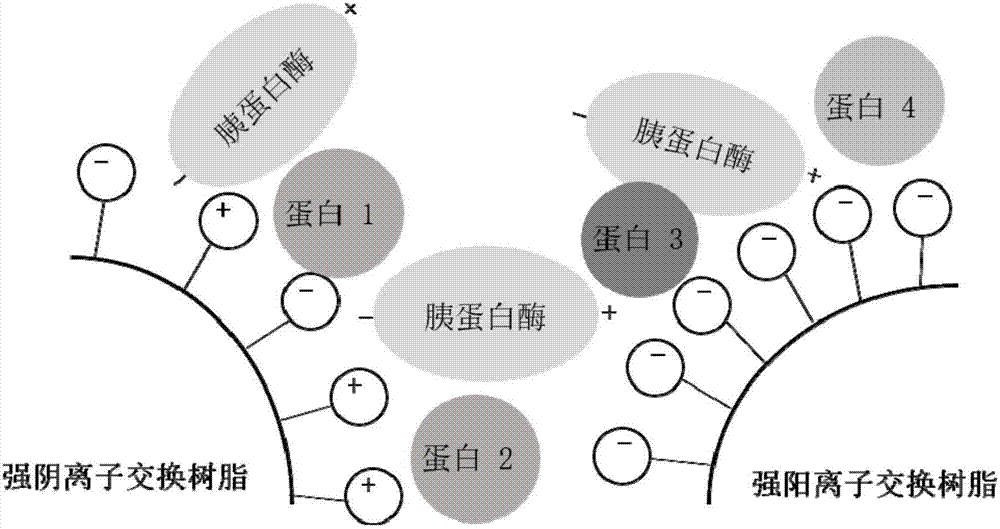

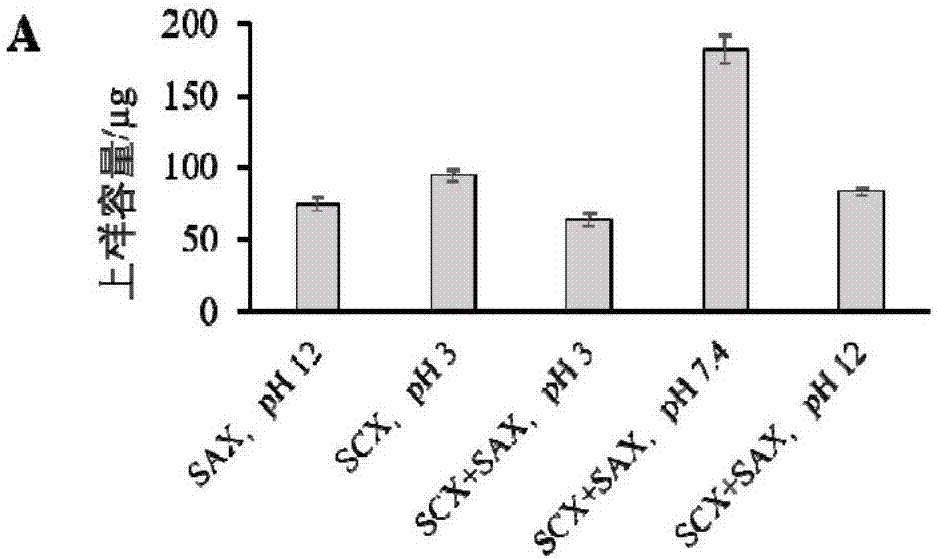

[0053] Example 2 The effect of pH value on the protein enrichment of SCX / SAX mixed fillers

[0054] In this example, the pH value of the protein enrichment of the SCX / SAX mixed filler is optimized, and the BCA test method is adopted.

[0055] For protein reactor devices based on SCX, SAX and SCX / SAX mixed media, place a pipette tip through an adaptor onto a 1.5 mL centrifuge tube. A piece of SCX membrane (3M Empore, USA) was placed on the bottom of the pipette tip to act as a fixed filler, and 50 μL SCX (20 mg / mL), 50 μL SAX (20 mg / mL) and 50 μL SCX / SAX (20 mg / mL) were filled on the SCX membrane respectively. mL) mixed filler. In the determination experiment of the loading capacity of SCX packing, firstly add 20 μL of 100 mM potassium citrate (pH 3) and 20 μL of 10 mM potassium citrate (pH 3) to pre-equilibrate the SCX packing; then replace a new 1.5 mL centrifuge tube, BSA (2 μg / μL) and LYZ (2 μg / μL) stock solutions were mixed 1:1, and the BSA and LYZ mixture was diluted 1:...

Embodiment 3

[0058] Example 3 Effect of pH value on protein enrichment of SCX / SAX mixed fillers

[0059] In this example, the SDS-PAGE method was adopted by optimizing the pH value of the protein enrichment of the SCX / SAX mixed filler.

[0060] In the determination experiment of the loading capacity of the SCX packing, firstly, 20 μL of 100 mM potassium citrate (pH 3) and 20 μL of 10 mM potassium citrate (pH 3) were sequentially added to pre-equilibrate the SCX packing. Then replace with a new 1.5mL centrifuge tube, mix BSA (2 μg / μL) and LYZ (2 μg / μL) stock solutions 1:1, and dilute the BSA and LYZ mixture 1:1 with 1% FA (pH 3) to contain A mixed solution of BSA (0.5 μg / μL) and LYZ (0.5 μg / μL). Take 30 μL of the diluted mixed solution of BSA and LYZ for sample loading, centrifuge for 5 min (300 rcf), and collect the effluent in the 1.5 mL centrifuge tube; ), collect the effluent in the 1.5 mL centrifuge tube; load the sample 7 times, and obtain 7 effluents in turn. The contents of BSA a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com