Anti-fogging and Anti-fouling laminate and method for producing same, article and method for producing same, and Anti-fouling method

A manufacturing method and anti-fouling layer technology, applied in lamination, layered products, lamination devices, etc., can solve problems such as low manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0241] The first embodiment is an example of the above-mentioned anti-fogging and anti-fouling layer forming process using a transfer original disk by using a photoresist having a predetermined pattern shape as a protective film on the transfer original disk. The surface is etched to form any of fine protrusions and recesses.

[0242] First, the transfer master and its manufacturing method will be described.

[0243] 〔Composition of the transfer master disk〕

[0244] Figure 3A It is a perspective view showing an example of the configuration of a roll master as a transfer master. Figure 3B will be Figure 3A An enlarged view of a portion of the roll master shown. Figure 3C Yes Figure 3B Profile plot in trajectory T. The roll master 231 is a transfer master for making the anti-fog and antifouling laminate with the above-mentioned structure, more specifically, the roll master 231 is used to form a plurality of Raw discs with convex or concave parts. The roll master 23...

no. 2 Embodiment approach

[0270] The second embodiment is an example of the above-mentioned anti-fogging and anti-fouling layer forming process using a transfer original disk formed by laser processing of the transfer original disk by irradiating a laser beam on the surface of the transfer original disk. Any of the fine protrusions and recesses is formed.

[0271] First, the transfer master and its manufacturing method will be described.

[0272] 〔Composition of the transfer master disk〕

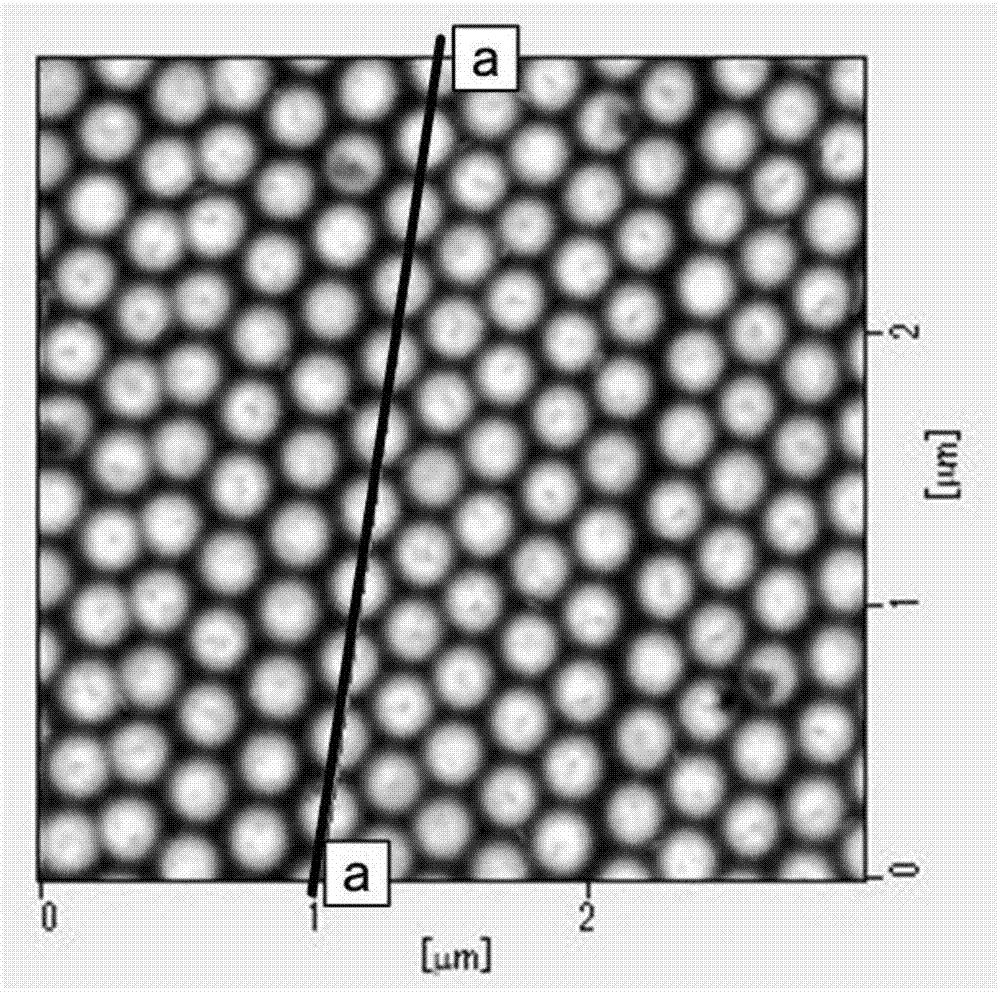

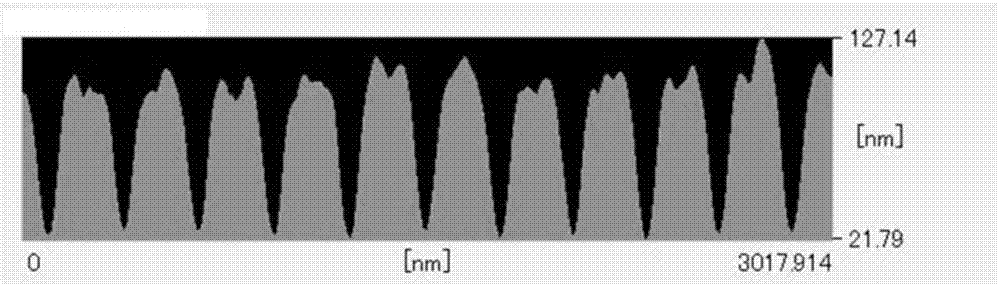

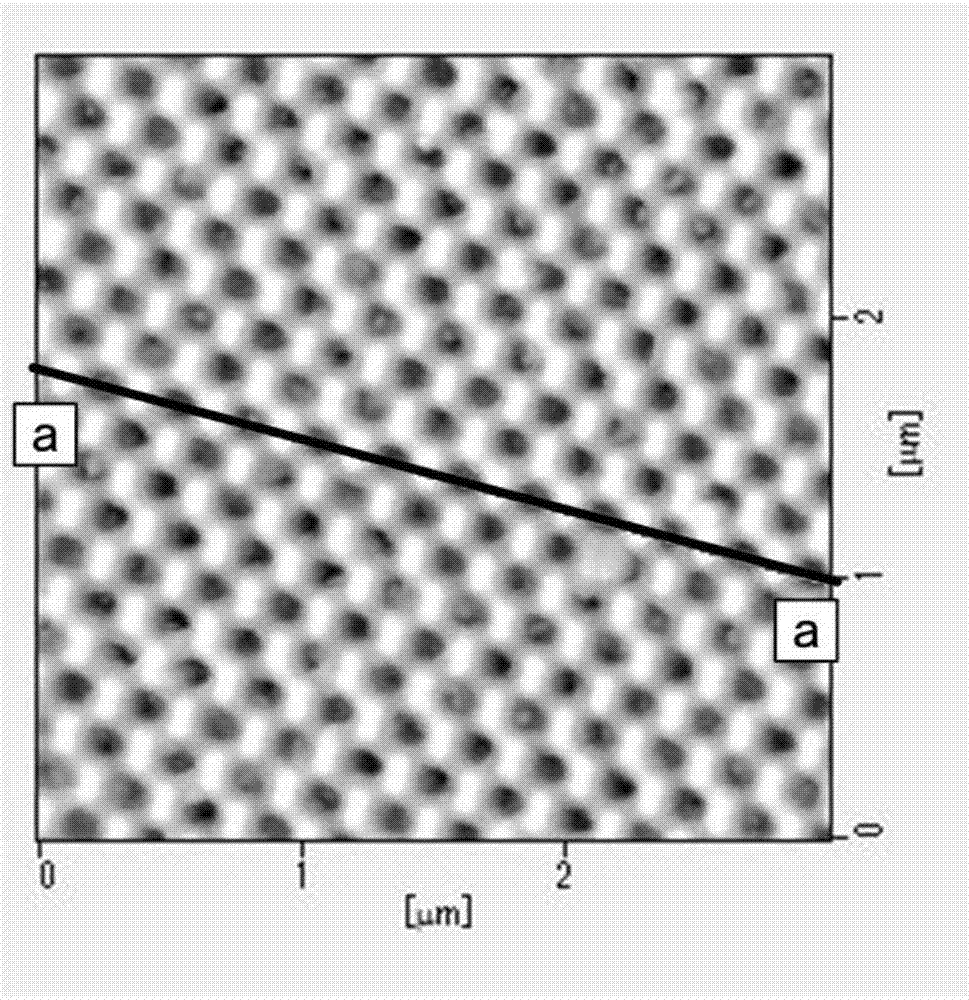

[0273] Figure 7A It is a plan view showing an example of the configuration of a plate-shaped original disk. Figure 7B is along Figure 7A The section view of line a-a is shown. Figure 7C will be Figure 7B Sectional view showing enlarged part of . The plate-shaped master 331 is a master for producing the anti-fog and anti-fouling laminated body having the above-mentioned structure. Or the original disk of the concave part. The plate-shaped master 331 has, for example, a surface provided with a fine concave-c...

Embodiment 1

[0423]

[0424] First, a glass roll master with an outer diameter of 126 mm was prepared, and a resist layer was formed on the surface of the glass roll master as follows. That is, the photoresist is diluted with a diluent at a mass ratio of 1 / 10, and the diluted resist is coated on the cylindrical surface of the glass roll master by a dipping method so that the average thickness becomes about 70 nm, thereby forming a resist Floor. Next, transport the glass roll master to the Figure 4 In the roll master exposure device shown in the figure, the resist layer is exposed to form a helical shape, and at the same time, a latent image of a hexagonal pattern is formed between three adjacent lines of tracks and is patterned on the resist layer. . Specifically, a laser beam of 0.50 mW / m was irradiated to a region where a hexagonal grid exposure pattern should be formed to form a hexagonal grid exposure pattern.

[0425]Next, developing treatment is performed on the resist layer on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com