Low-energy-consumption green tea washing device

A technology of cleaning equipment and low energy consumption, applied in the direction of tea processing before extraction, can solve the problems of time-consuming and labor-intensive, unclean cleaning, and inability to thoroughly clean tea stains, etc., to achieve efficient removal and improve the effect of discharging speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

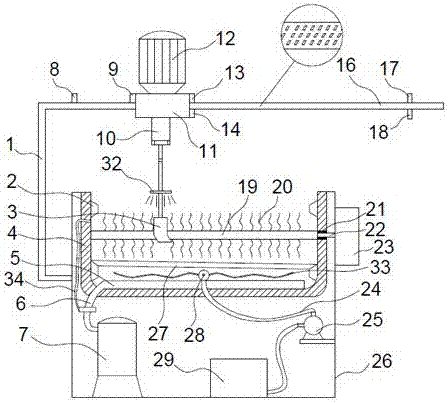

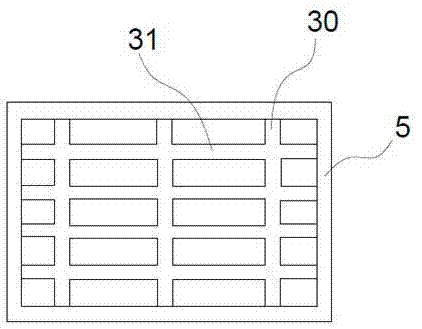

[0022] Such as Figure 1-4As shown, a green tea cleaning device with low energy consumption includes a support 26, a water tank 4 placed above the inside of the support 26, a stirring rod 19 horizontally placed in the middle of the water tank 4, an air compressor 7 and a storage tank 29 arranged below the inside of the support 26, The air compressor 7 is connected with a reversing valve, and the reversing valve is respectively connected to the air delivery pipe 6 and the drying pipe 34. The air delivery pipe 6 penetrates the water tank 4 and is connected to the bubble generation pipeline 5 horizontally arranged at the bottom of the water tank 4. The air bubble generation pipeline 5 is a mesh pipeline, and the mesh pipeline is composed of a number of longitudinal bubble pipes 30 and a number of horizontal bubble pipes 31. The longitudinal bubble pipes 30 and the horizontal bubble pipes 31 are connected to each other, which is beneficial to the generation of air bubbles. The air ...

Embodiment 2

[0027] Such as Figure 1-4 As shown, when the green tea cleaning equipment with low energy consumption of the present invention actually works: the green tea is cleaned by combining the ultrasonic generator 2 with the bubble generation pipeline 5 and the bucket 3 moving back and forth in the water tank 4, and the bubbles occur The bubbles produced by the pipeline 5 can stir the green tea and improve the effect of cavitation. When the sound pressure or sound intensity reaches a certain level, the bubbles will expand rapidly and then close suddenly. During this process, the bubbles Shock waves are generated at the moment of closure, causing a pressure of 1012-1013pa and local temperature adjustment around the bubbles. The huge pressure generated by this ultrasonic cavitation can destroy insoluble dirt and make them differentiate in the solution. The bubble generation pipeline 5 is installed in The bottom of the water tank 4 realizes that the air bubbles emerge upward from the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com