Preparation method and application of wastewater chromium PEI/ZSM-5 (polyethyleneimine/zeolite socony mobil-5) modified absorbent

A technology of ZSM-5 and adsorbent, which is applied in the field of adsorbent preparation, can solve the problems such as the large influence of ZSM-5 adsorption capacity, and achieve the effects of low cost, good application prospect and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

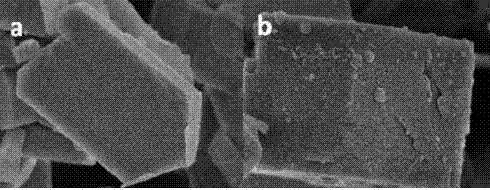

Image

Examples

Embodiment 1

[0036] Preparation of chromium adsorbent:

[0037] (a) Acid modification of ZSM-5 molecular sieve: Grind the commercially available ZSM-5 molecule (silicon-aluminum ratio is 38) to 100 mesh, according to the solid-liquid ratio of ZSM-5 and methanol 1:10 (g:mL) ZSM-5 was dissolved, sonicated under ultrasonic conditions for 15 minutes, vacuum filtered and dried at 100°C for 2 hours after standing still. Put the dried sample in a beaker, add dilute hydrochloric acid so that the solid-liquid ratio of ZSM-5 and dilute hydrochloric acid is 1:5 (g:mL), sonicate under ultrasonic conditions for 15min, vacuum filter and dry at 110°C After 2 hours, grind to 100 mesh to obtain the acid-modified ZSM-5 molecular sieve.

[0038] (b) Dissolve PEI (molecular weight: 600) in methanol according to the ratio of PEI to methanol 1:10 (g:mL), sonicate under ultrasonic conditions for 15 minutes, add 1.5g of acid-modified ZSM-5 to the above PEI / methanol solution, sonicated for 15min, dried at 110°C...

Embodiment 2

[0042] Preparation of chromium adsorbent:

[0043] (a) Acid modification of ZSM-5 molecular sieve: Grinding commercially available ZSM-5 (silicon-aluminum ratio 60) to 100 mesh, according to the solid-liquid ratio of ZSM-5 and methanol 1:5 (g:mL) -5 was dissolved, sonicated under ultrasonic conditions for 15 minutes, vacuum filtered and dried at 90°C for 2 hours after standing still. Put the dried sample in a beaker, add hydrochloric acid so that the solid-to-liquid ratio of ZSM-5 and dilute hydrochloric acid is 2:5 (g:mL), sonicate under ultrasonic conditions for 15min, vacuum filter and dry at 100°C for 2h , Grind to 100 meshes to obtain the acid-modified ZSM-5 molecular sieve.

[0044](b) Dissolve PEI (molecular weight 1800) in methanol according to the ratio of PEI to methanol at 1:5 (g:mL), sonicate under ultrasonic conditions for 15 minutes, add 1.5 g of acid-modified ZSM-5 molecular sieve to the above PEI / methanol solution, sonicated for 15min, dried at 100°C for 2h, ...

Embodiment 3

[0048] Preparation of chromium adsorbent:

[0049] (a) Acid modification of ZSM-5 molecular sieve: Grinding the commercially available ZSM-5 molecular sieve (silicon-aluminum ratio of 120) to 100 mesh, according to the solid-liquid ratio of ZSM-5 and methanol 3:10 (g:mL) ZSM-5 was dissolved, sonicated under ultrasonic conditions for 15 minutes, vacuum filtered and dried at 100°C for 2 hours after standing still. Put the dried sample in a beaker, add hydrochloric acid so that the solid-liquid ratio of ZSM-5 and dilute hydrochloric acid is 1:5 (g:mL), sonicate under ultrasonic conditions for 15min, vacuum filter and dry at 100°C for 2h , Grind to 100 meshes to obtain the acid-modified ZSM-5 molecular sieve.

[0050] (b) Dissolve PEI (molecular weight 3000) in methanol according to the ratio of PEI to methanol at 1:10 (g:mL), sonicate under ultrasonic conditions for 15 minutes, add 1.5 g of acid-modified ZSM-5 molecular sieve to the above PEI / methanol solution, sonicated for 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com