Method for decontaminating, cleaning and disinfecting food contact surface

A food and cleaning technology, applied in the direction of cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of cleaning cycle steps and time extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0067] Example 1 : Conduct laboratory studies to generate cleaning efficiency data for different CIP compositions and protocol phases. A basic CIP protocol has five stages: a) rinse with water, b) first chemical effect, c) rinse with water, d) second chemical effect and e) rinse with water; in addition there is a final disinfection step.

[0068] Preparation of test models: Soiled food panels were obtained by the following method.

[0069] A. Clean the stainless steel panels with ethanol and dry in a hot air oven at 105°C for 1 hour. Weigh it to 4 digits. It was then placed in an oven preheated to 220°C. A 2 ml liquid food sample (eg Lipton iced tea / tomato soup) is applied to an area of approximately 20 cm2. It was baked at 220°C for 1 hour. The panels were then cooled and weighed again to 4 digits.

[0070] B. Piping pieces containing tea soil and milk tea soil were collected from the actual tea and coffee beverage manufacturing site and cut into small boards / panels....

example 2

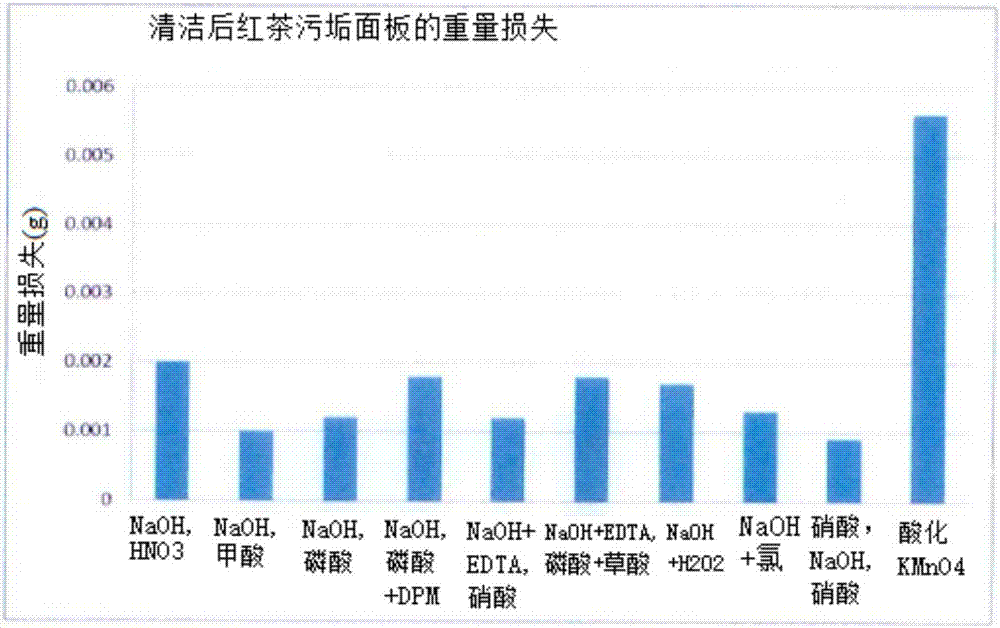

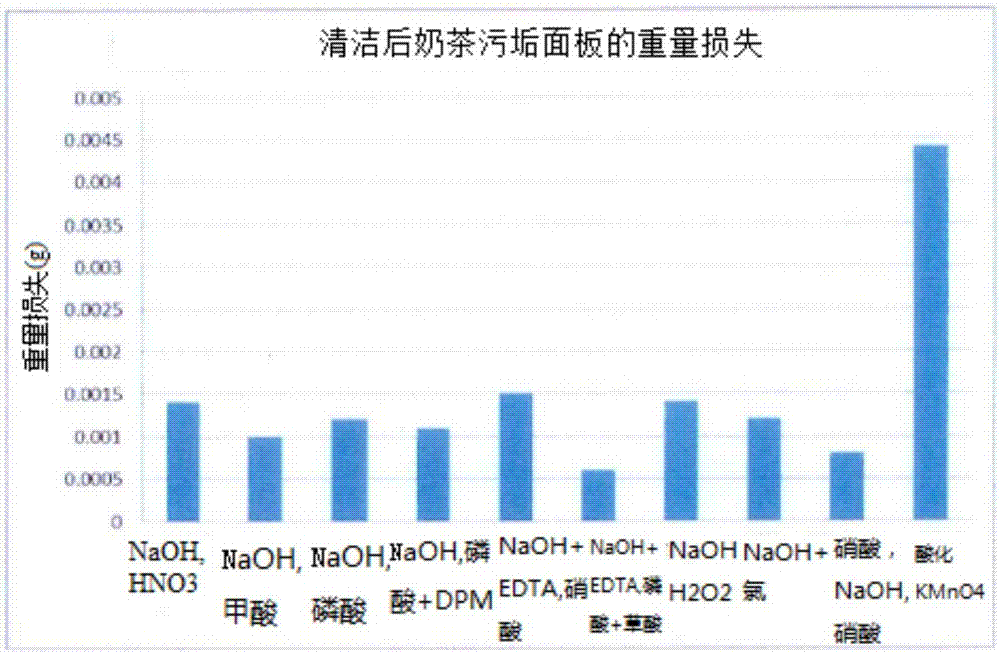

[0071] Example 2 : demonstrates the in-situ cleaning of panels with black and milk tea soils obtained according to the method described in Example 1B). After the pre-rinse step, the test panel is placed in the beaker containing the first chemical solution at the desired temperature. It should be noted that the temperatures described herein are the temperatures of the reagents for a given time by CIP. It was further rinsed with water and placed in a second chemical solution. Finally, rinse again with water and dry in an oven at 100° C. for 1 hour. Record the weight of each cleaned panel to calculate weight loss. Details of the cleaning compositions are reported in Table 1 below.

[0072] In this cleaning evaluation, each test panel was evaluated for visual observation and weight loss after cleaning.

[0073] It can be seen from Tables 2 and 3 that the combination of oxidizing agent and acid has a significant cleaning synergistic effect, while caustic is completely incapab...

example 3

[0083] Example 3: Additionally, two specific protocols were performed to examine the cleaning efficiency of potassium permanganate as given below.

[0084] Scheme 1: Place the dirt panel in a solution containing 5% sodium hydroxide and 0.5% potassium permanganate at a solution temperature of 80° C. for 30 minutes. Rinse with water at room temperature. The panels were then removed and placed in a solution comprising 0.77% nitric acid, 0.14% phosphoric acid and 1% ferrous sulfate at a temperature of 80° C. for 10 minutes. The panels were dried in an oven at 100°C for 1 hour.

[0085] Protocol 2: The soiled panel was placed in a solution containing 1.9% nitric acid and 0.35% phosphoric acid and 0.5% potassium permanganate at a temperature of 50 to 80° C. for 30 minutes. Rinse with water with 0.005% w / w peracetic acid and 0.02% w / w hydrogen peroxide at room temperature. The panels were dried in an oven at 100°C for 1 hour.

[0086] Visual observation:

[0087] Alkaline pota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com