Method for preparing fatty alcohol through in-situ hydrogenation of fatty acid

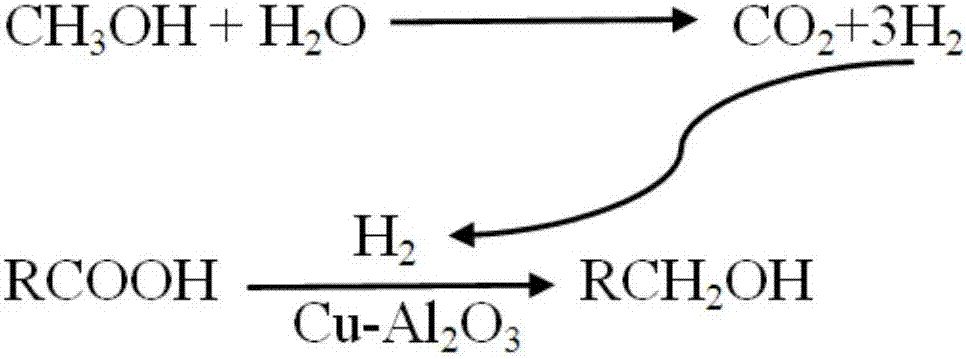

An in-situ hydrogenation and fatty acid technology is applied in chemical instruments and methods, preparation of hydroxyl compounds, and preparation of organic compounds. It can solve problems such as high price, reduced purity of reaction products, and obstacles to industrialization. The effect of economy, reduction of pollution and harm to human body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

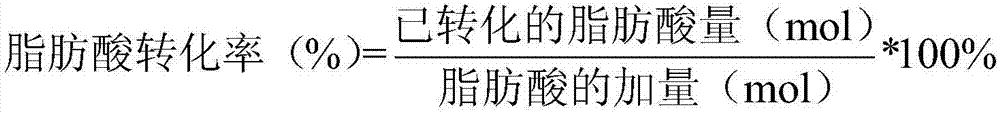

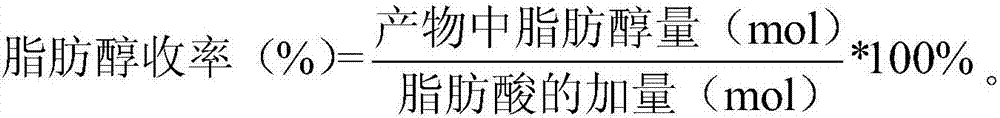

Embodiment 1

[0034] Add 5g lauric acid, 5g methanol, 1.5gCu-Al 2 o 3 Mix with 50mL deionized water, stir, heat up to 330°C and react for 3h, after the reaction is over, cool to room temperature, the liquid phase product is allowed to stand and separate, and the separated organic phase is fixed to volume with acetone, then quantitatively analyzed by GC-FID, and the calculation The conversion rate of lauric acid was 100%, and the molar yield of dodecyl alcohol was 99.1%.

Embodiment 2

[0036] According to the preparation in Example 1, only the amount of methanol added was changed to 0.5 g, the calculated conversion rate of lauric acid was 21.1%, and the molar yield of dodecanol was 20.9%.

Embodiment 3

[0038] According to the preparation in Example 1, only changing the amount of methanol added to 1 g, the calculated conversion rate of lauric acid is 45.4%, and the molar yield of dodecanol is 44.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com