Antibacterial rubber glove and preparation method thereof

A technology of antibacterial rubber gloves and antibacterial agent, applied in protective clothing and other directions, can solve the problem that the growth and reproduction of harmful bacteria cannot be effectively inhibited.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

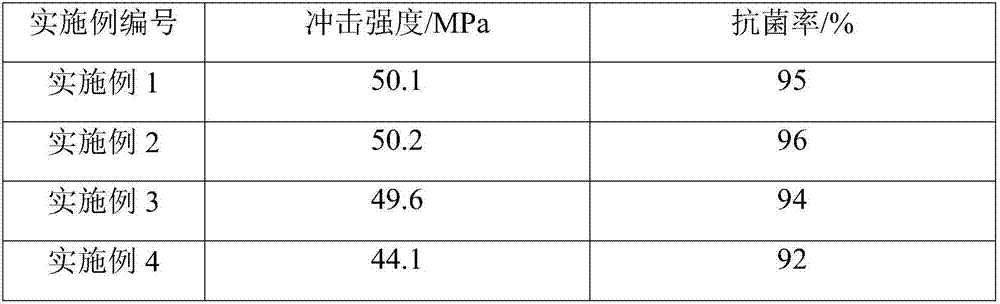

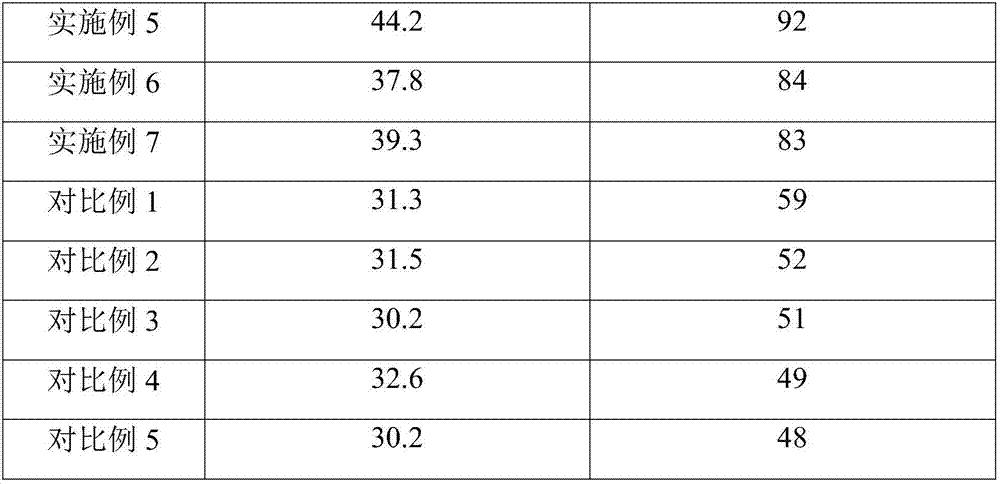

Examples

preparation example Construction

[0015] The invention provides a kind of preparation method of antibacterial rubber gloves, it is characterized in that, described preparation method comprises:

[0016] (1) soak natural rubber in liquid antibacterial agent, take out after 2-3h, obtain antibacterial rubber raw material; Wherein, liquid antibacterial agent is selected from 2-n-octyl-4-isothiazolin-3-ketone and / or n- Butylbenzisothiazolinone;

[0017] (2) Mix the antibacterial rubber raw material, polyethylene wax, zinc oxide, pentaerythritol and N-phenylmaleimide, and carry out the first internal mixing at 60-80° C. to obtain the first mixed rubber;

[0018] (3) mixing the first mixed rubber, nano-silver, anti-aging agent and accelerator, and performing the second internal mixing at 85-95° C. to obtain the second mixed rubber;

[0019] (4) Add the second mixed rubber into the vulcanizer, extrude, vulcanize and shape to obtain antibacterial rubber gloves; wherein, the extrusion conditions include: the temperatur...

Embodiment 1

[0033] Soak the natural rubber in the liquid antibacterial agent and take it out after 2 hours to obtain the antibacterial rubber raw material; wherein the liquid antibacterial agent is selected from 2-n-octyl-4-isothiazolin-3-one and n-butylbenzisothiazoline Ketone; 100g antibacterial rubber raw material, 4g polyethylene wax, 4g zinc oxide, 14g pentaerythritol and 4gN-phenylmaleimide are mixed, and carry out banburying for the first time at 60°C to obtain the first mixing rubber; 100g of the first mixed rubber, 6g of nano-silver, 3g of anti-aging agent and 2g of accelerator are mixed, and the second mixed rubber is carried out at 85°C to obtain the second mixed rubber; Extrusion, vulcanization and thermocompression molding (the temperature of thermocompression molding is 110 ℃, and the pressure of thermocompression molding is 20Mpa.), obtain antibacterial rubber gloves A1; Wherein, the condition of extruding comprises: the temperature of machine head is 65 ℃, The temperature ...

Embodiment 2

[0035] Soak the natural rubber in the liquid antibacterial agent, take it out after 2-3h, and obtain the antibacterial rubber raw material; wherein, the liquid antibacterial agent is selected from 2-n-octyl-4-isothiazolin-3-one; 100g antibacterial rubber raw material, 6g of polyethylene wax, 6g of zinc oxide, 16g of pentaerythritol and 7g of N-phenylmaleimide were mixed, and the first internal mixing was carried out at 80°C to obtain the first mixed rubber; 100g of the first mixed rubber, 8g Nano-silver, 5g anti-aging agent and 3g accelerator are mixed, and the second internal mixing is carried out at 95°C to obtain the second compound rubber; the second compound rubber is added to the vulcanizer, and is extruded, vulcanized and hot-pressed (The temperature of thermocompression molding is 120 ℃, and the pressure of thermocompression molding is 30Mpa), obtains antibacterial rubber glove A2; Wherein, the condition of extruding comprises: the temperature of machine head is 70 ℃, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com