Carbon nanotube conductive ball as well as preparation method and application thereof

A technology of carbon nanotubes and conductive balls, which is applied in the field of conductive adhesives, can solve problems such as carbon nanotube detachment and reduced conductivity, and achieve the effects of improving conductivity, reducing risks, and reducing puncture risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

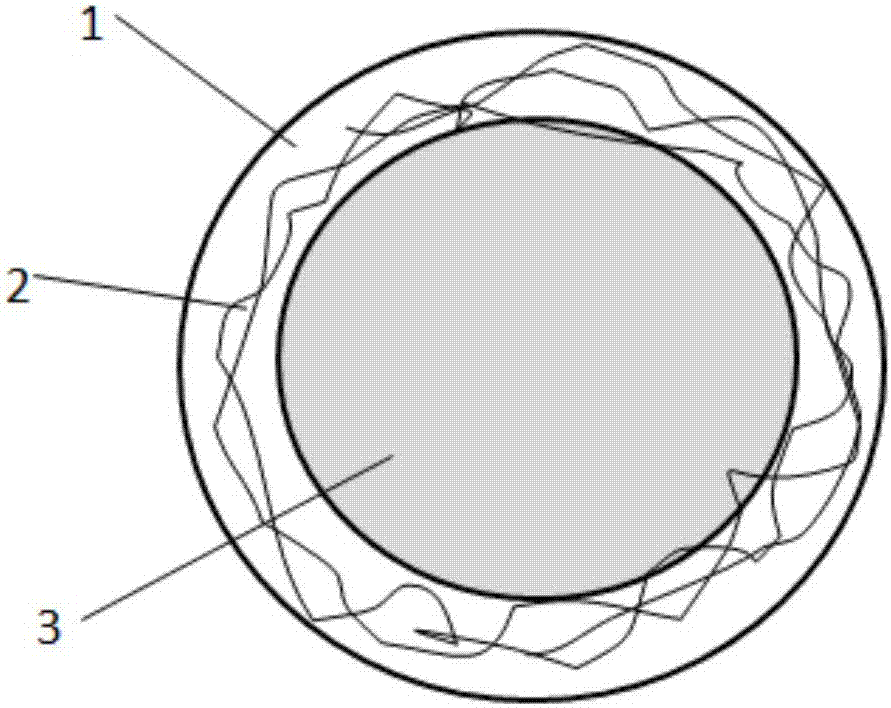

[0033] A carbon nanotube conductive ball, the conductive ball has a core-shell structure, wherein the core is a silicon ball with a diameter of 2 μm, and the shell layer is polyethylene doped with carbon nanotubes.

[0034] Its preparation method is as follows:

[0035] Provide carbon nanotubes with a length of 15-20um and a diameter of 1-2nm, polyethylene, and silicon spheres with a diameter of 2μm.

[0036] Heat polyethylene above its melting point to make it flow, and then disperse carbon nanotubes in polyethylene according to the mass ratio of carbon nanotubes and polyethylene at a ratio of 1:99. In this process, stirring is used to accelerate carbon Dispersion of nanotubes in polyethylene, finally prepared polyethylene doped with 1wt% carbon nanotubes.

[0037] Maintain the heating state, mix the polyethylene doped with carbon nanotubes and cue balls according to the mass ratio of 0.5:1, stir to disperse the cue balls evenly, and after standing for a period of time, disc...

Embodiment 2

[0039] A carbon nanotube conductive ball, the conductive ball has a core-shell structure, wherein the core is a polymer microsphere with a diameter of 10 μm, and the shell layer is polyvinyl chloride doped with carbon nanotubes.

[0040] Its preparation method is as follows:

[0041] Carbon nanotubes with a length of 20-25 μm and a diameter of 1.5-2 nm, polyvinyl chloride, and polymer microspheres with a diameter of 10 μm are provided.

[0042] Heat polyvinyl chloride above its melting point to make it flow, carbon nanotubes are pre-acidified, and then carbon nanotubes and polyvinyl chloride are dispersed in polyvinyl chloride according to the mass ratio of 20:80. In vinyl chloride, stirring is used to accelerate the dispersion of carbon nanotubes in polyvinyl chloride during this process, and finally polyvinyl chloride doped with 20 wt% carbon nanotubes is obtained.

[0043] Maintain the heating state, mix the polyvinyl chloride doped with carbon nanotubes with the cue ball ...

Embodiment 3

[0045] A carbon nanotube conductive ball, the conductive ball has a core-shell structure, wherein the core is a silicon ball with a diameter of 20 μm, and the shell layer is polypropylene doped with carbon nanotubes.

[0046] Its preparation method is as follows:

[0047] Carbon nanotubes with a length of 15-20 μm and a diameter of 1-2 nm, polypropylene, and silicon spheres with a diameter of 20 μm were provided.

[0048] Heating the polypropylene above its melting point to make it flow, the carbon nanotubes are pre-aminated, and then the carbon nanotubes and polypropylene are dispersed in the polypropylene according to the mass ratio of 15:85. In this process, ultrasound is used to accelerate the dispersion of carbon nanotubes in polypropylene, and finally polypropylene doped with 15wt% carbon nanotubes is obtained.

[0049] Maintain the heating state, mix the polypropylene doped with carbon nanotubes with the cue ball at a mass ratio of 0.2:1, stir to help it disperse evenly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com