Sonochemical preparation method for CsPbBr3 quantum dots

A technique for preparing cesium-lead-bromide perovskite and sonochemistry, which is applied in the field of information materials, can solve problems such as large organic waste liquid, complex operation, unfavorable quantum dot reaction kinetics, and achieve energy saving, simple reaction conditions, and excellent Effect of Optical Unity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

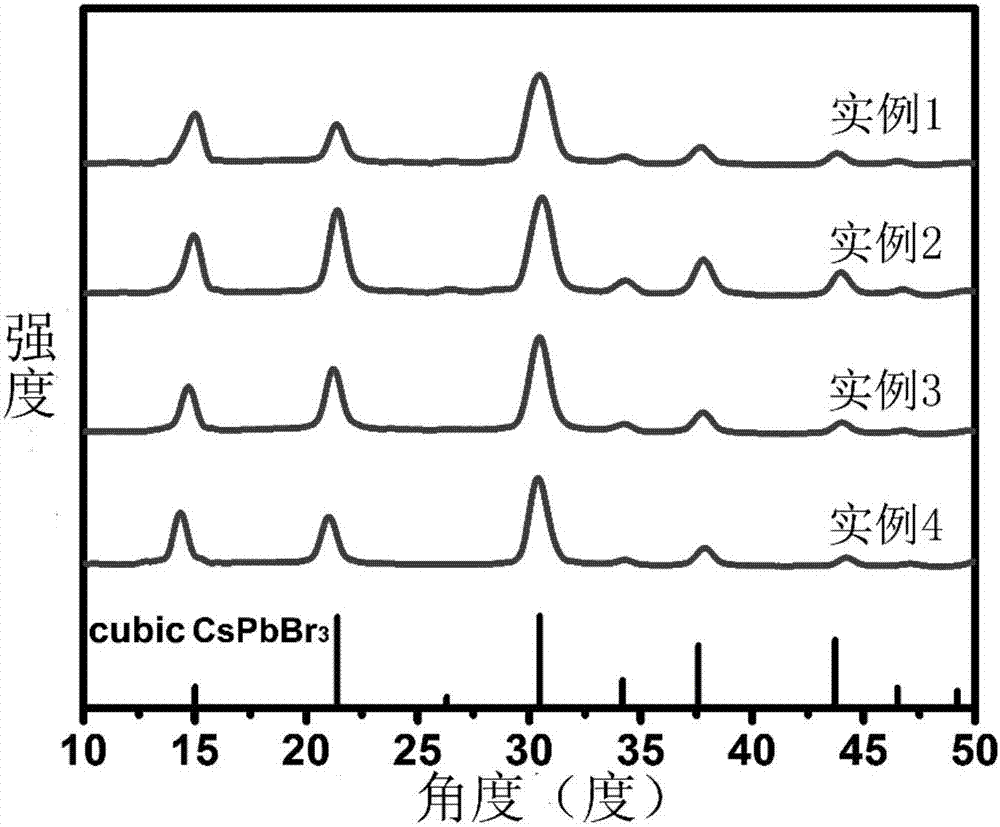

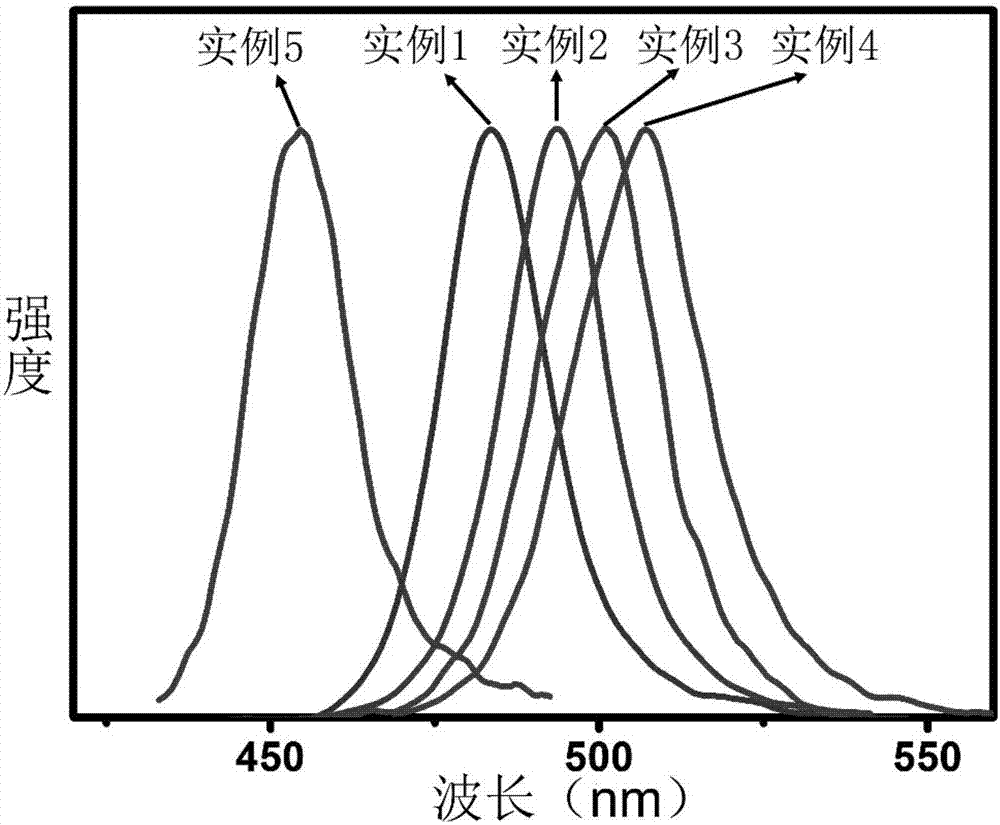

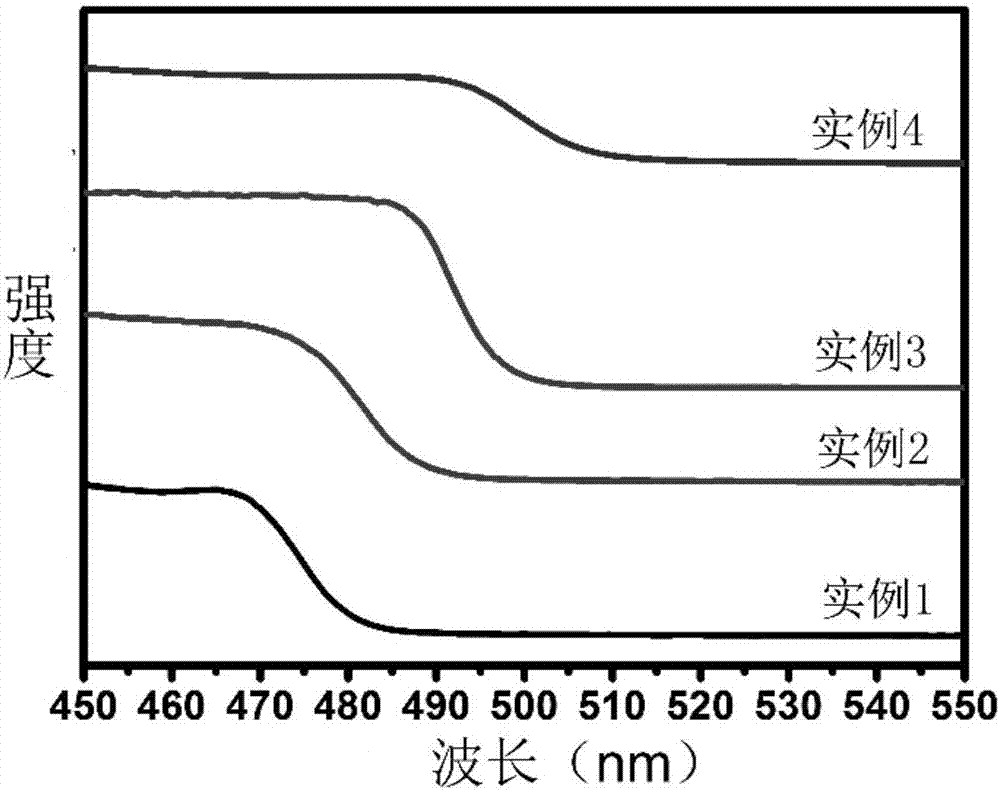

Embodiment 1

[0033] A kind of sonochemical synthesis of cesium lead bromide perovskite quantum dots (CsPbBr 3 ), the specific steps are as follows:

[0034] (1) Put 0.8gCs 2 CO 3 Dissolve in 30ml 1-octadecene, heat to 80℃ under nitrogen atmosphere, add 2.5ml oleic acid, wait for Cs 2 CO 3 After completely dissolved, cool to room temperature to obtain solution R 1 ;

[0035] (2) 0.132gPbBr 2 Dissolve in 10ml 1-octadecene, heat to 80℃ under nitrogen atmosphere, add 1ml oleic acid and 1ml oleylamine, wait for PbBr 2 After completely dissolved, cool to room temperature to obtain solution R 2 ;

[0036] (3) The liquid R obtained in the above steps (1) (2) 1 And R 2 Mix evenly according to the ratio of 1:10 to get R 3 . Mixed solution R 3 Transfer to a glass container, put it in an ultrasonic cleaning machine, and sonicate it with 250W power for 30min;

[0037] (4) Dissolve the liquid obtained in step (3) in toluene, centrifuge and wash with toluene 3 times, and finally disperse the solution in toluene ...

Embodiment 2

[0040] A kind of sonochemical synthesis of cesium lead bromide perovskite quantum dots (CsPbBr 3 ), the specific steps are as follows:

[0041] (1) Put 4g Cs 2 CO 3 Dissolve in 150ml 1-octadecene, heat to 80℃ under nitrogen atmosphere, add 12.5ml oleic acid, wait for Cs 2 CO 3 After completely dissolved, cool to room temperature to obtain solution R 1 ;

[0042] (2) Add 0.66g PbBr 2 Dissolved in 50ml 1-octadecene, in N 2 Heat to 80℃ in a gas atmosphere, add 5ml oleic acid and 5ml oleylamine, wait for PbBr 2 After completely dissolved, cool to room temperature to obtain solution R 2 ;

[0043] (3) The liquid R obtained in the above steps (1) (2) 1 And R 2 Mix evenly according to the ratio of 1:10 to get R 3 . Mixed solution R 3 Transfer to a glass container, put it in an ultrasonic cleaning machine, sonicate at 250W power for 60min;

[0044] (4) Dissolve the liquid obtained in step (3) in toluene, centrifuge and wash with toluene 3 times, and finally disperse the solution in toluene to...

Embodiment 3

[0047] A kind of sonochemical synthesis of cesium lead bromide perovskite quantum dots (CsPbBr 3 ), the specific steps are as follows:

[0048] (1) Put 0.8g Cs 2 CO 3 Dissolved in 30ml 1-octadecene, in N 2 Heat to 80°C under air atmosphere, add 2.5ml oleic acid, wait for Cs 2 CO 3 After completely dissolved, cool to room temperature to obtain solution R 1 ;

[0049] (2) 0.132gPbBr 2 Dissolved in 10ml 1-octadecene, in N 2 Heat to 80°C in an air atmosphere, add 1ml oleic acid and 1ml oleylamine, wait for PbBr 2 After completely dissolved, cool to room temperature to obtain solution R 2 ;

[0050] (3) The liquid R obtained in the above steps (1) (2) 1 And R 2 Mix evenly according to the ratio of 1:10 to get R 3 . Mixed solution R 3 Transfer to a glass container, put it in an ultrasonic cleaning machine, and sonicate it at 250W for 120min;

[0051] (4) Dissolve the liquid obtained in step (3) in toluene, centrifuge and wash with toluene 3 times, and finally disperse the solution in toluen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com