Economical tool steel with good fatigue life and production method thereof

A technology of fatigue life and production method, applied in the field of metallurgy, can solve the problems of high manufacturing cost, long manufacturing cycle, large energy consumption, etc., and achieve the effects of improving product yield, shortening manufacturing cycle, and shallow decarburization layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

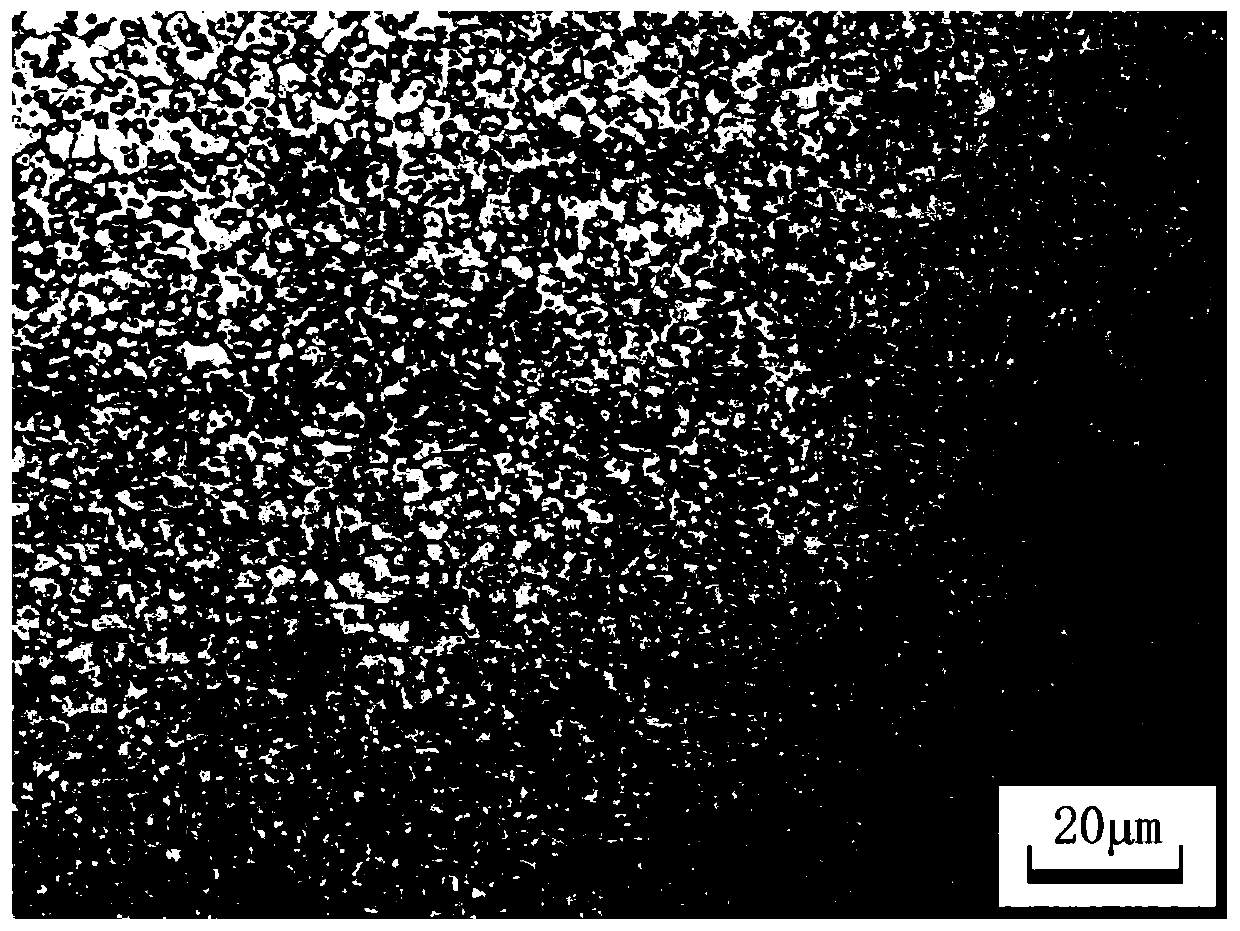

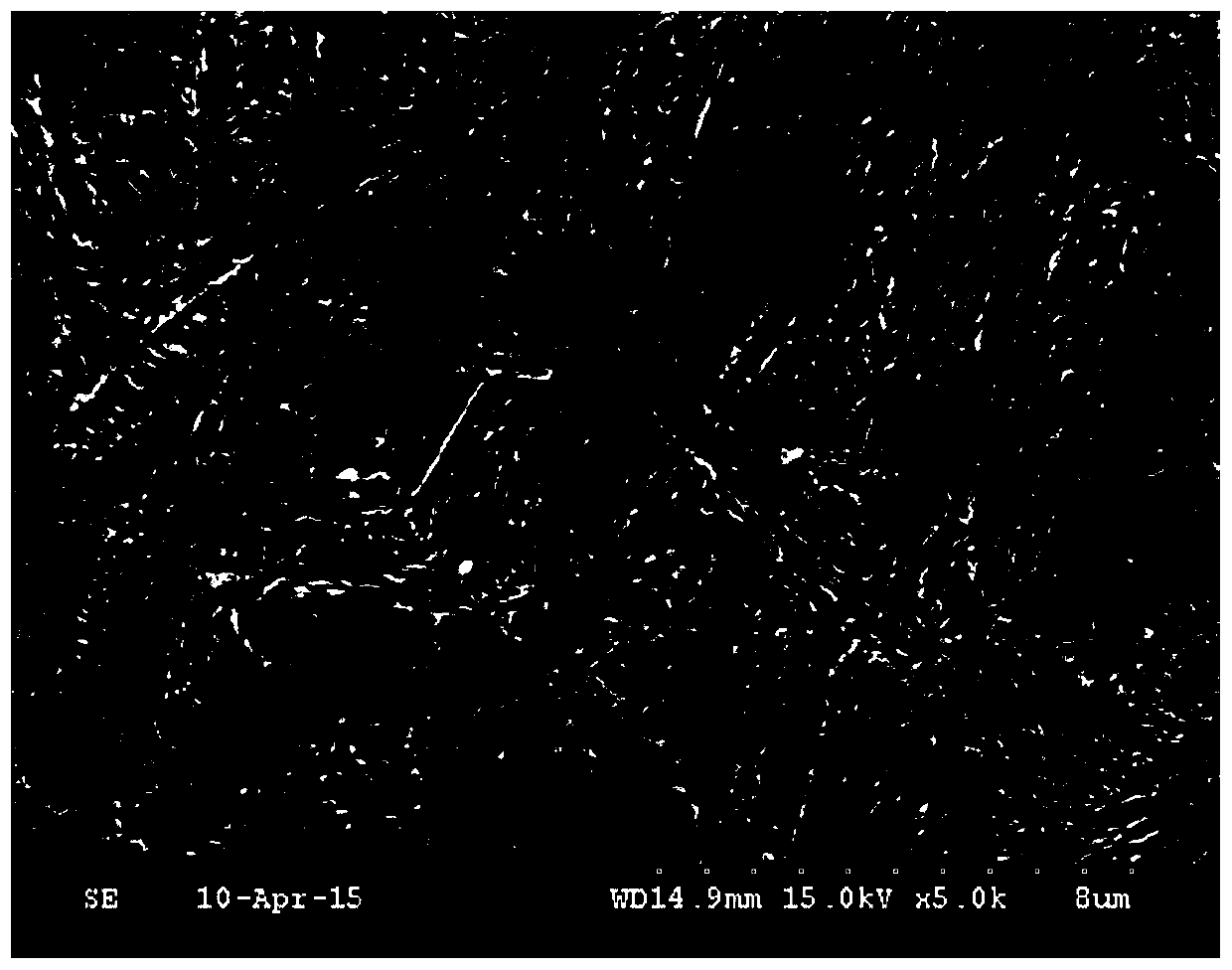

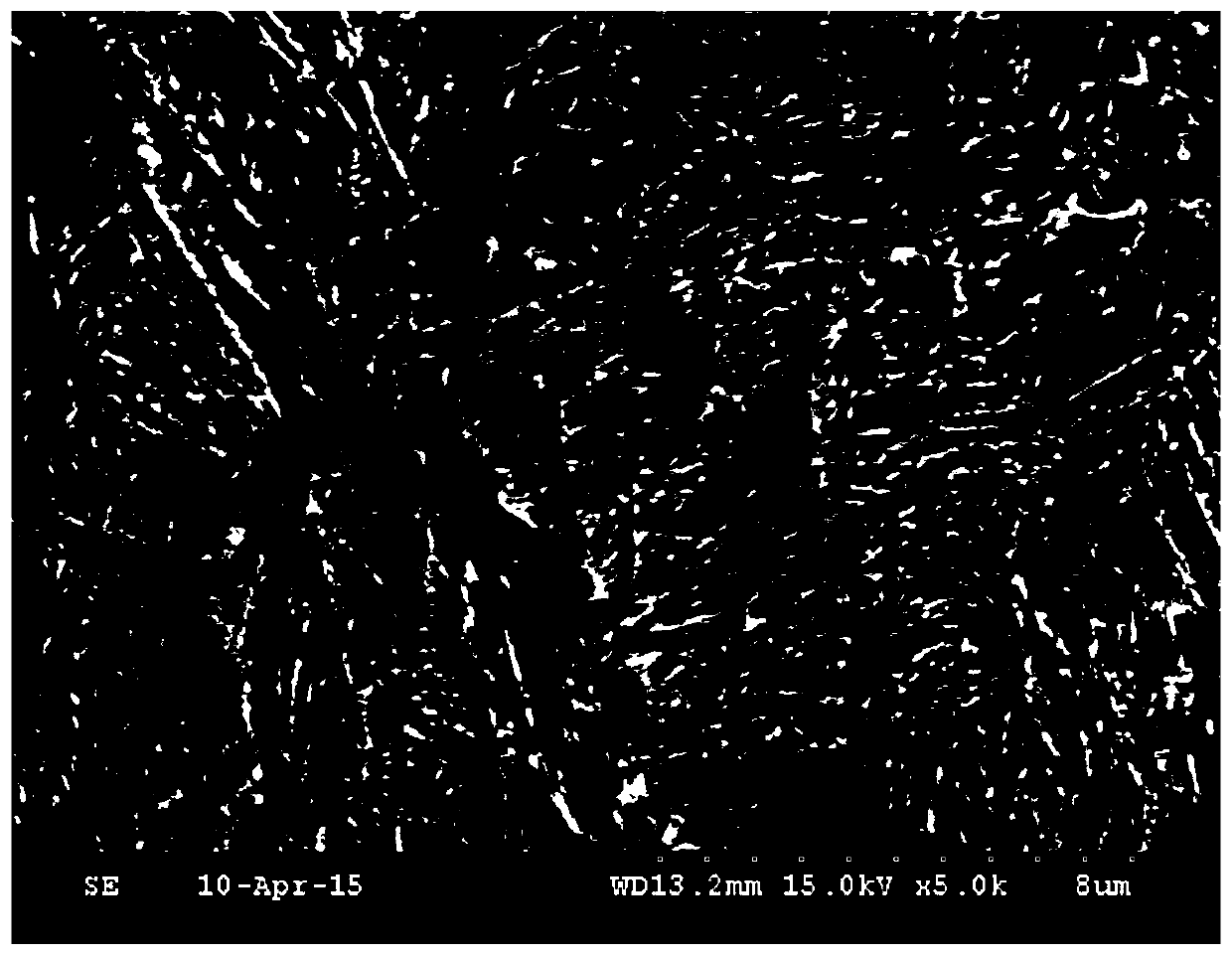

Image

Examples

Embodiment 1~5

[0034] Each embodiment of the present invention is produced according to the following steps:

[0035] 1) Smelting: The carbon content of the steel from the converter is ≥0.05%, and after the deoxidation is completed, add ferrovanadium, and soft blow for 3-8 minutes after calcium treatment in the later stage of refining;

[0036] 2) Continuous casting: the nozzle is sealed with argon to avoid oxygen and nitrogen absorption during the molten steel casting process, the superheat is 15-30°C, and the thickness of the billet is 200-250mm;

[0037] 3) Heating: the billet heating temperature is 1150-1250°C, and the holding time is 30-90 minutes;

[0038] 4) Rough rolling: the starting rolling temperature is 1030-1130°C, the final rolling temperature is 900-980°C, the thickness of the intermediate billet is 45-60mm, and the single-pass reduction rate is ≥45%;

[0039] 5) Finish rolling: the starting rolling temperature is 820-900°C, the final rolling temperature is 630-680°C, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com