Metallization coating method for through hole of film circuit

A thin-film circuit and metallization technology, applied in the field of thin-film circuit through-hole metallization coating, can solve the problems of diffraction and sputtering film layers, etc., and achieve the effect of simple operation, solving peeling off, and easy and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

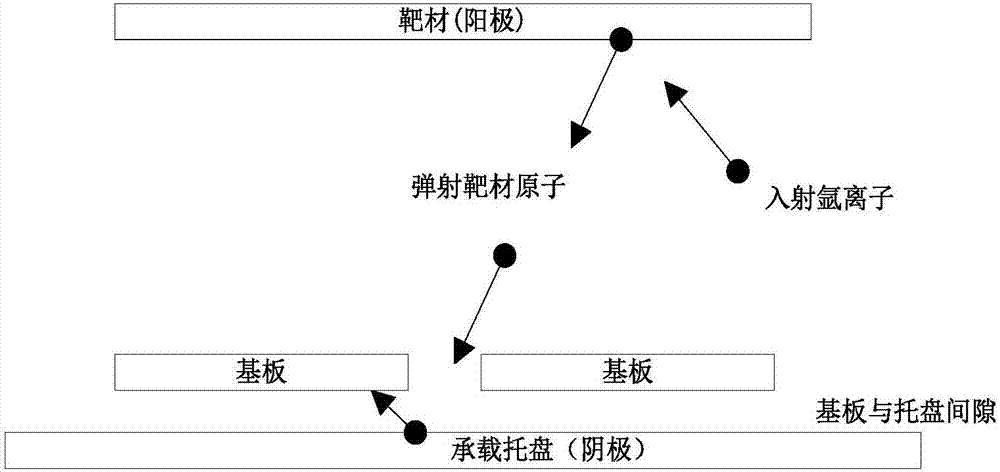

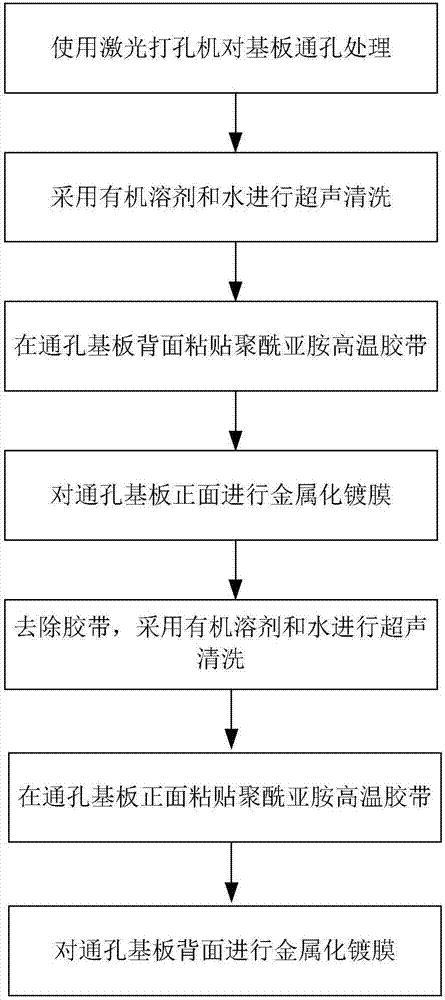

[0031] combine figure 1 and figure 2 , a thin film circuit through-hole metallization coating method, comprising the following steps:

[0032] Step 1: Provide a thin film circuit substrate of the required type and size, and use a laser drilling machine to perform through-hole processing on the thin film circuit substrate.

[0033] The thin film circuit substrate is made of aluminum oxide substrate with a purity of more than 99.6% or an aluminum nitride substrate or a quartz substrate with a purity of 98%, and the thickness of the substrate is 0.1mm to 0.65mm. For example, the selected hard dielectric substrate material is alumina ceramics with a purity of 99.6%, and a thickness of 0.254mm. Use a laser drilling machine, set the spiral interval to 0.01mm, automatically position through the equipment, scan 200 times with an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com