Preparation of porous quasi-solidus electrochromism PVB electrolyte membrane with electrostatic spinning method and preparing technology thereof

An electrospinning method and electrochromic technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as easy leakage of liquid or gel electrolyte, difficulty in application by Chinese enterprises, and impact on product service life. Conducive to ion transmission, get rid of industry monopoly, good electrochromic performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

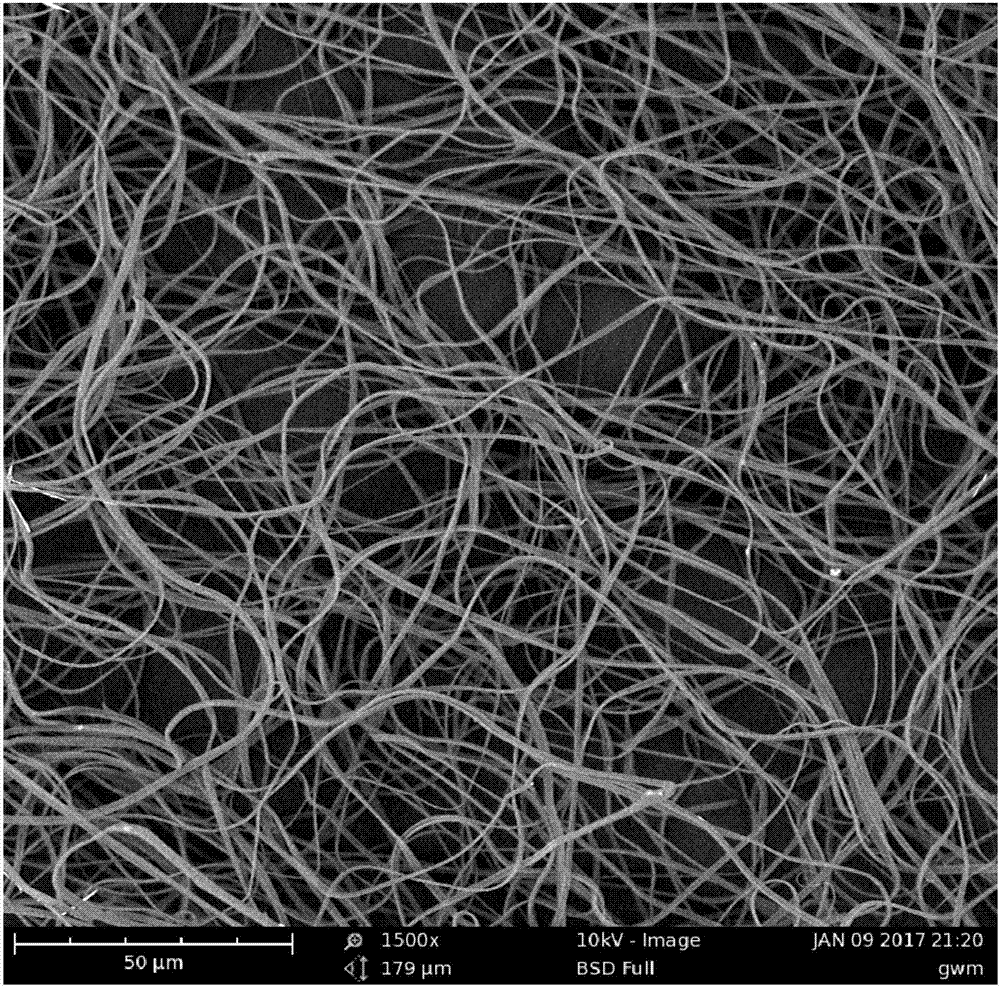

[0031] 1) At room temperature, weigh 5 g of polyvinyl butyral (PVB) and dissolve it in 100 g of ethanol. After 12 hours of magnetic stirring, a clear and transparent solution is obtained, and then ultrasonically treat the resulting solution for 20 minutes to make it uniformly dispersed. Prepare the spinning solution, set the electrospinning voltage to 12kV, the distance between the syringe needle and the receiving plate to 15cm, the flow rate of the spinning solution to 1mL / h, and the electrospinning time to 5min. The spinning solution is spun into a porous film and then peeled off , lay flat on a petri dish, and dry the petri dish and the prepared PVB electrolyte film in an oven at a temperature of 40°C;

[0032] 2), weigh 110g of lithium perchlorate, dissolve it in 1000mL propylene carbonate, and prepare a liquid electrolyte after fully stirring, and remove moisture from the propylene carbonate solution of lithium perchlorate obtained in the previous steps through a vacuum ov...

Embodiment 2

[0037] 1) At room temperature, weigh 5 g of polyvinyl butyral (PVB) and dissolve it in 100 g of ethanol. After 12 hours of magnetic stirring, a clear and transparent solution is obtained, and then ultrasonically disperses the obtained solution for 20 minutes to make it uniformly dispersed. To obtain the spinning solution, set the electrospinning voltage to be 15kV, the distance between the syringe needle and the receiving plate to be 15cm, the flow rate of the spinning solution to be 1mL / h, and the electrospinning time to be 8min. Lay it flat on a petri dish, and dry the petri dish together with the prepared PVB electrolyte film in an oven at 40°C;

[0038] 2), weigh 110g of lithium perchlorate, dissolve it in 1000mL propylene carbonate, and prepare a liquid electrolyte after fully stirring, and remove moisture from the propylene carbonate solution of lithium perchlorate obtained in the previous steps through a vacuum oven at a temperature of 80 degrees Celsius , the vacuum de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com