Method for manufacturing semiconductor epitaxial wafer and method for manufacturing solid-state imaging device

A manufacturing method, epitaxial wafer technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve insufficient problems and achieve the effect of high gettering capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

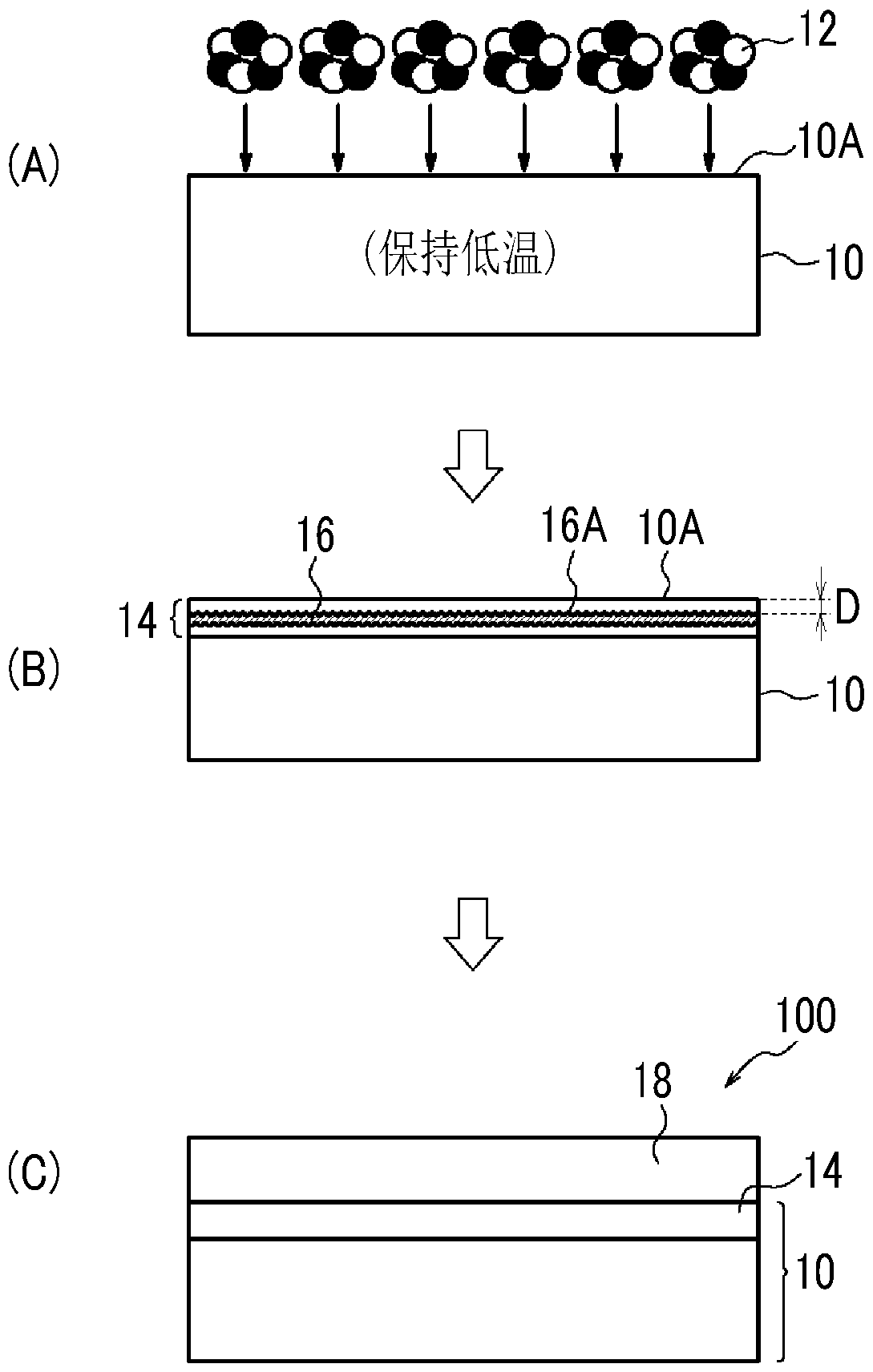

[0072] An n-type silicon wafer (diameter: 300 mm, thickness: 725 μm, dopant: phosphorus, dopant concentration: 5.0×10 14 atom / cm 3 ). Next, the C 3 h 5 Clusters are irradiated onto the surface of the silicon wafer to form a modified layer. The substrate temperature and the dose of carbon at this time were the conditions described in Table 1. The acceleration voltage per carbon atom is 23.4keV / atom, the beam current value is 800μA, the tilt (Tilt): 0°, and the twist (Twist): 0°.

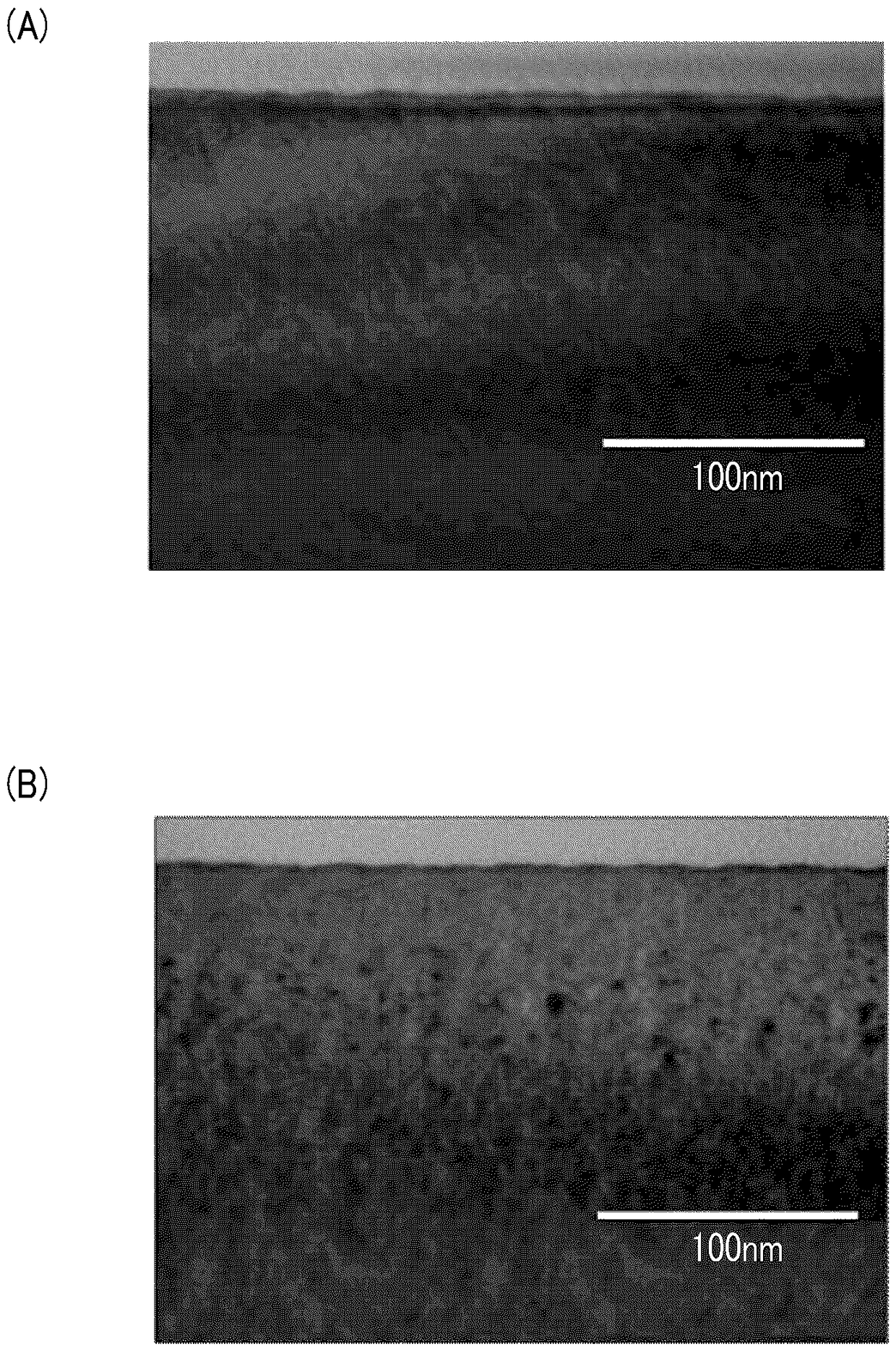

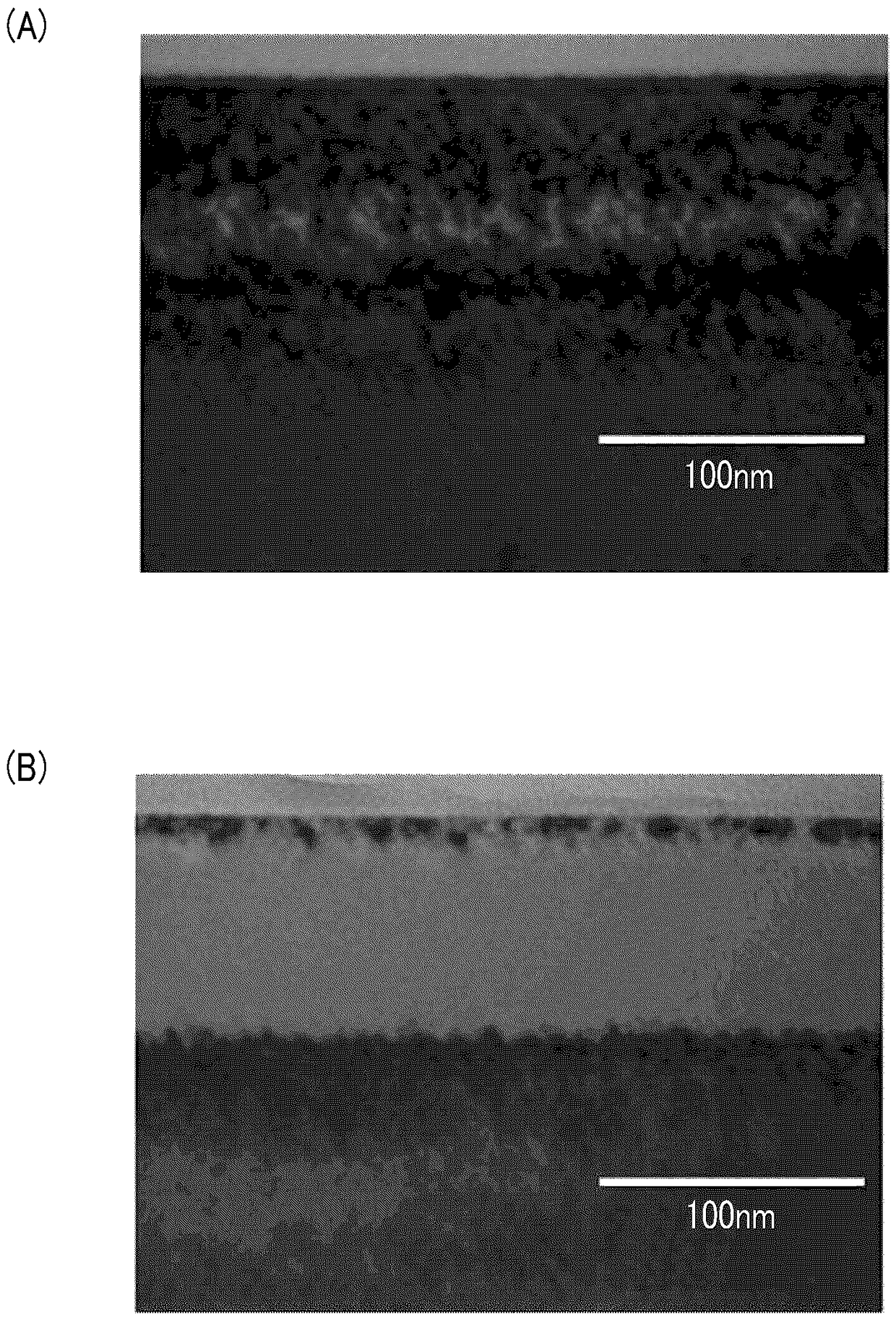

[0073] The cross section around the modified layer immediately after cluster ion irradiation was observed by TEM. Table 1 shows the presence or absence of the amorphous layer, the average depth of the surface, and the thickness in each experimental example. As a representative, No.5 in Table 1 is expressed in figure 2 In (A), No.7 is shown in figure 2 (B). In addition, No. 13 and No. 14 are shown in image 3 (A), image 3 (B). In the figure, the whitish portion is seen to be an amorphous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com