Low-smoke ethylene-propylene-diene monomer coating layer

A technology of EPDM and EPDM rubber, applied in the field of solid propellants, can solve problems affecting laser guidance signal transmission, missile off-target, ablation, carbonization, etc., to reduce smoke, increase strength, and improve carbonization effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

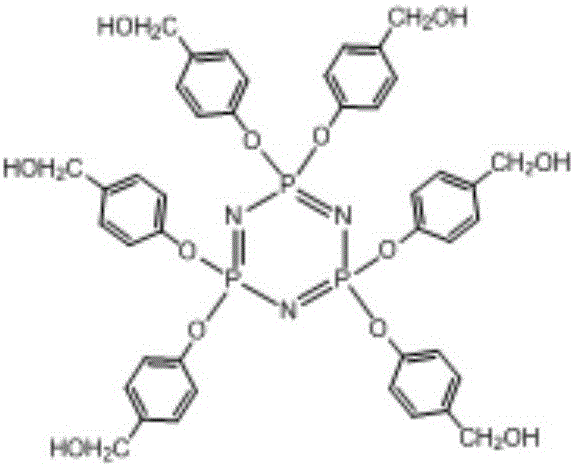

[0013] This embodiment is implemented according to the following mass percentage composition: 77% EPDM rubber, 1.4% cumene peroxide, 0.7% sulfur, 3.7% zinc borate, 3.7% trichloroethyl phosphate, 6.5% polyimide Pulp, 7% hexa(4-hydroxymethylphenoxy) cyclotriphosphazene.

[0014] The preparation method of the coating is as follows:

[0015] (1) Double-roll mill, with a roll distance of 5mm, mixes EPDM rubber to make the rubber roll;

[0016] (2) Add zinc borate, hexa(4-hydroxymethylphenoxy) cyclotriphosphazene, and trichloroethyl phosphate and mix for 10 minutes;

[0017] (3) Add polyimide pulp and mix for 20 minutes;

[0018] (4) Add sulfur and cumene peroxide, mix for 10 minutes, and produce a 2mm thick green film;

[0019] (5) The raw film is vulcanized in a flat vulcanizer.

[0020] In the performance test of the examples, the smoke performance of the coating layer was tested according to WJ20187-2016; the results are as follows: the laser transmittance is 91.2%, and the visible light t...

Embodiment 2

[0022] This embodiment is implemented according to the following mass percentage composition: 80% EPDM rubber, 1.4% cumene peroxide, 0.6% sulfur, 3.5% zinc borate, 3.5% trichloroethyl phosphate, 5% polyimide Pulp, 6% hexa(4-hydroxymethylphenoxy) cyclotriphosphazene.

[0023] In this embodiment, the laser transmittance of the coating layer is 90.1%, and the visible light transmittance is 80.8%.

Embodiment 3

[0025] This embodiment is implemented according to the following mass percentage composition: 75% EPDM rubber, 1.4% cumene peroxide, 0.6% sulfur, 4% zinc borate, 4% trichloroethyl phosphate, 7% polyimide Pulp, 8% hexa(4-hydroxymethylphenoxy) cyclotriphosphazene.

[0026] In this embodiment, the laser transmittance of the coating layer is 90.8%, and the visible light transmittance is 81.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com