Nuclear power 1E-grade K3-class heat-shrinkable tubing material and preparation thereof

A heat-shrinkable sleeve, nuclear power technology, applied in the direction of circuits, electrical components, insulated cables, etc., to achieve the effects of excellent mechanical properties, excellent heat resistance, and excellent radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

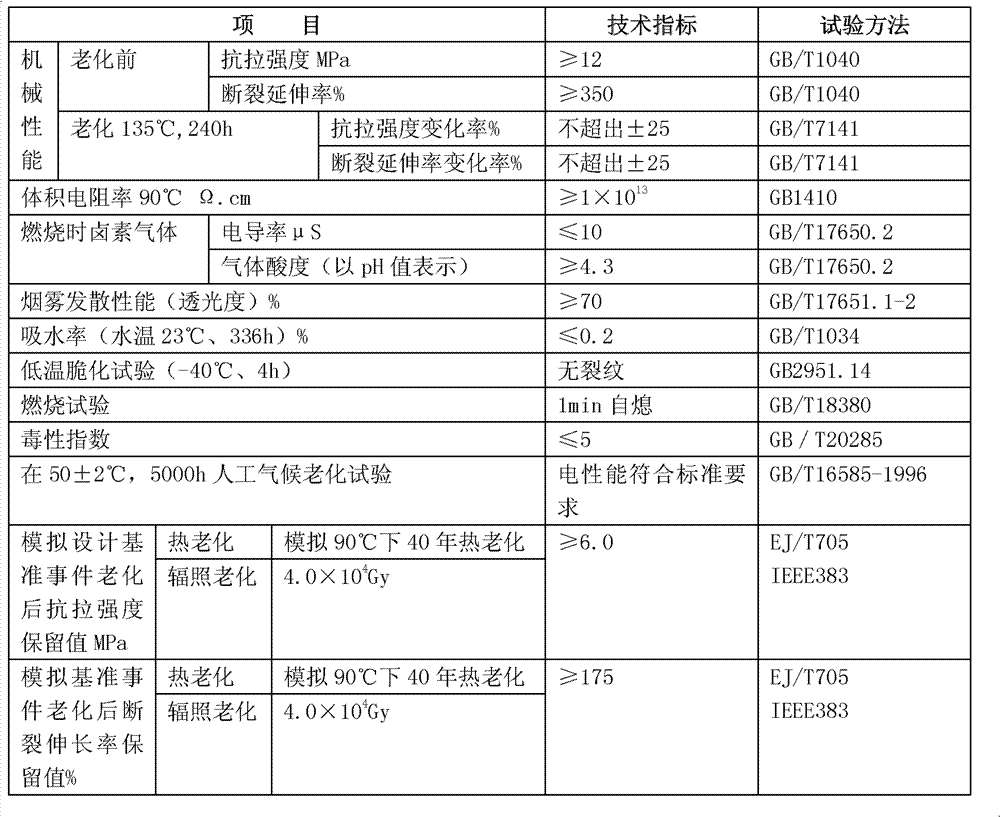

Image

Examples

Embodiment 1

[0049]29g POE (Model 810), 31g EVA (Model 260), 37g EPDM 3072EM, 3.5g antioxidant RD, 1.8g antioxidant MB, 2g antioxidant 1010, 34g coupling treated aluminum hydroxide, 20g coupling Add magnesium hydroxide after joint treatment, 15g nitrogen-based flame retardant FR-PN, 15g zinc borate, 3g silicone rubber (120-1), 1.5g colorant (N330) and 0.1g ultraviolet light absorber OB into the internal mixer In the process, knead at 135°C for 20 minutes to complete the first internal mixing and granulation, where the temperature of each section of the granulator is 130°C, 130°C, and 130°C; and then knead at 135°C for 15 minutes to complete The second banburying and granulation; then mix the masterbatch of the second banburying and granulation at 135°C for 10 minutes, add 5g of lubricant fly-off, 2ml of sensitizer (TAIC), and mix at 135°C Practice for 10 minutes. Obtain the masterbatch of nuclear power 1E grade K3 heat-shrinkable sleeve material, press the masterbatch with a flat vulcaniz...

Embodiment 2

[0051] 29g POE (model 810), 18g EVA (model 260), 13g EVA (model 14-2), 37g EPDM 3072EM, 3.5g antioxidant RD, 1.8g antioxidant MB, 2g antioxidant 1010, 34g coupling Treated aluminum hydroxide, 20g coupling treated magnesium hydroxide, 15g nitrogen-based combustion additive FR-PN, 15g zinc borate, 3g silicone rubber (120-1), 1.5g colorant (N330) and 0.1g ultraviolet light The absorbent OB is added to the internal mixer, and mixed at 135°C for 20 minutes to complete the first internal mixing and granulation. The temperature of each section of the granulator is 130°C, 130°C, and 130°C; and then mixed at 135°C After 15 minutes of refining, complete the second internal mixing and granulation; then mix the masterbatch for the second internal mixing and granulation at 135°C for 10 minutes, then add 5g of lubricant and 2ml of sensitizer (TAIC) , and kneaded at 135° C. for 10 minutes. Obtain the masterbatch of nuclear power 1E grade K3 heat-shrinkable sleeve material, press the masterb...

Embodiment 3

[0053] Put 29g POE (model 810), 31g EVA (model 14-2), 37g EPDM rubber (model 3072EM), 3.5g antioxidant RD, 1.8g antioxidant MB, 2g antioxidant 1010, 34g coupling treated hydrogen Alumina, 20g magnesium hydroxide after coupling treatment, 15g nitrogen-based combustion additive FR-PN, 15g zinc borate, 3g silicone rubber (120-1), 1.5g colorant (N330) and 0.1g ultraviolet light absorber OB Put it into the internal mixer, mix at 135°C for 20 minutes, and complete the first internal mixing and granulation, where the temperature of each section of the granulator is 130°C, 130°C, 130°C; then mix at 135°C for 15 minutes Finally, complete the second banburying and granulation; then mix the masterbatch of the second banburying and granulation at 135°C for 10 minutes, add 5g of lubricant, 2ml of sensitizer (TAIC), and mix at 135°C °C for 10 minutes. Obtain the masterbatch of nuclear power 1E grade K3 heat-shrinkable sleeve material, press the masterbatch with a flat vulcanizing machine t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com