Intelligent biomass straw degradation device and use method thereof

A biomass straw and ozone generating device technology, which is applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problems of high lignin content and low degradation reaction efficiency, and achieve benefits Evaporation, accelerated degradation reaction rate, clear working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

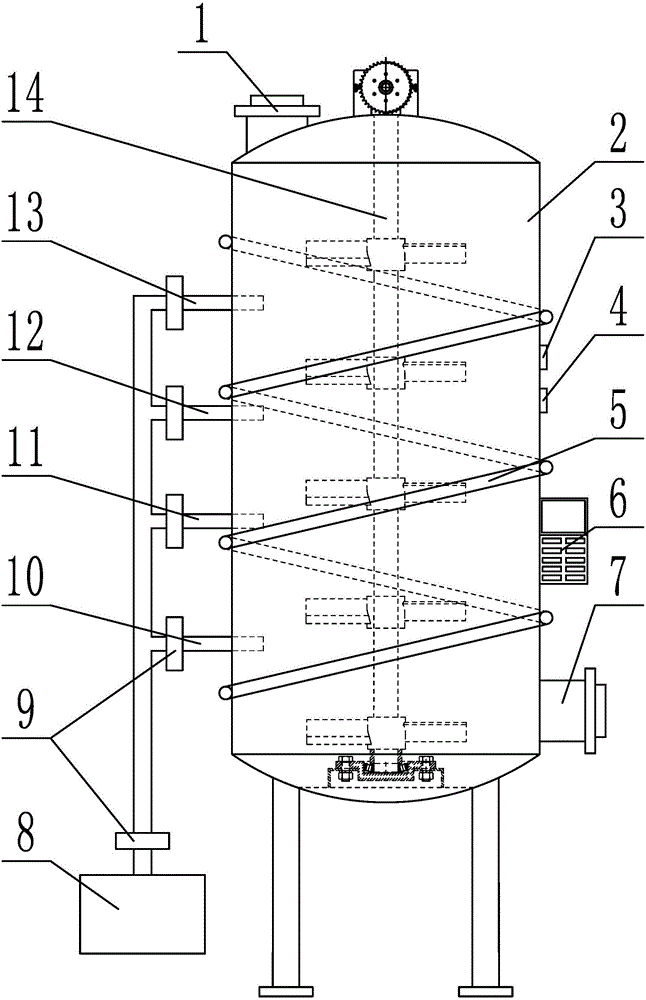

[0017] The present invention will be further described below in conjunction with accompanying drawing:

[0018] Such as figure 1 As shown, an intelligent biomass straw degradation device includes a sealed degradation tank 2, a material inlet 1, a material outlet 7, a stirring shaft 14, a spiral heating tube 5, an ozone generator 8, a flow control valve 9, and an ozone delivery Pipe one 10, ozone conveying pipe two 11, ozone conveying pipe three 12, ozone conveying pipe four 13, temperature sensor 4, pressure sensor 3, display controller 6. The sealed degradation tank 2 is vertically arranged; the biomass straw feed port 1 is arranged on the top of the sealed degradation tank, and a biomass straw outlet 7 is arranged at the bottom of the side wall of the sealed degradation tank to facilitate the entry and exit of the biomass straw powder. Degradation tank 2; the stirring shaft 14 is arranged in the middle of the sealed degradation tank 2, so as to realize the uniform and suffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com