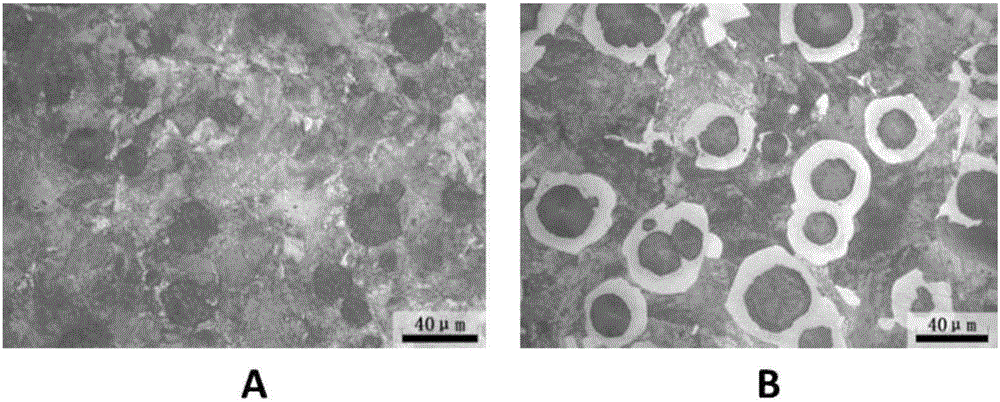

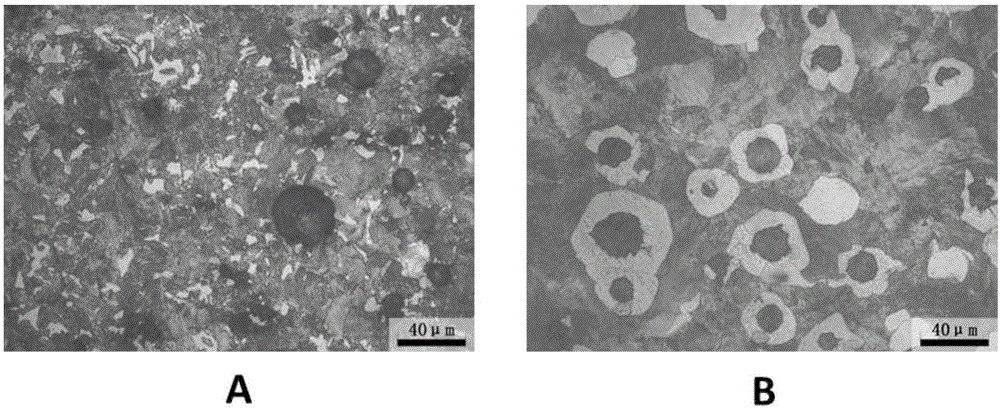

Fragmentation-type ferrite pearlitic structure high strength and toughness nodular cast iron and production method thereof

A technology of nodular cast iron and ferrite, which is applied in the field of high-strength nodular cast iron and its production, can solve the problems of complex production process and high cost, and achieve the effects of high elongation, high impact toughness and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 The production process of broken type ferrite plus pearlite high-strength and tough ductile iron crankshaft is as follows:

[0018] (1) Composition ratio: by weight percentage, C: 3.5-3.9%, Si: 1.7-2.1%, Mg: 0.03-0.05%, Cu: 0.4-0.8%, Mn: 0.3-0.6%, Sb: 0.006 -0.02%, S≤0.025%, P≤0.06%, Re: 0.012-0.015%, total content of other impurities≤0.02-0.05%, the balance is Fe;

[0019] (2) Charge selection: 5% of low-P and low-S scrap steel and 10% of iron filings are used, 35% of the return charge, and the rest are high-purity pig iron, which is used as the charge according to the composition ratio of step (1);

[0020] (3) Smelting and refining: use the intermediate frequency induction furnace to melt the charge to obtain molten iron, add industrial ferromanganese 0.6%, industrial ferrosilicon 1.0% and electrolytic copper 0.5% according to the composition ratio of step (1) for uniform smelting, and release after desulfurization and refining. The furnace temperature ...

Embodiment 2

[0029] (1) Composition ratio: by weight percentage, C: 3.5-3.9%, Si: 1.7-2.1%, Mg: 0.03-0.05%, Cu: 0.4-0.8%, Mn: 0.3-0.6%, Sb: 0.006 -0.02%, S<0.025%, P<0.06%, Re: 0.012-0.015%, the total content of other impurities is ≤0.02-0.05%, and the balance is Fe;

[0030] (2) Charge selection: 5% of low-P and low-S scrap steel and 10% of iron filings are used, 35% of the return charge, and the rest are high-purity pig iron, which is used as the charge according to the composition ratio of step (1);

[0031] (3) Smelting and refining: use the intermediate frequency induction furnace to melt the charge to obtain molten iron, add industrial ferromanganese 0.6%, industrial ferrosilicon 1.0% and electrolytic copper 0.5% according to the composition ratio of step (1) for uniform smelting, and release after desulfurization and refining. The furnace temperature is: 1480℃;

[0032] (4) Spheroidizing treatment: Z6S spheroidizing agent is selected, and the addition ratio is 0.9%;

[0033] (5) I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com