Field effect transistor and forming method therefor

A technology of field effect transistors and gates, applied in the field of field effect transistors and their formation, can solve the problems of unfavorable device size reduction, excessive width of side walls, etc., and achieve the effects of reducing distance, simplifying process, and enhancing stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

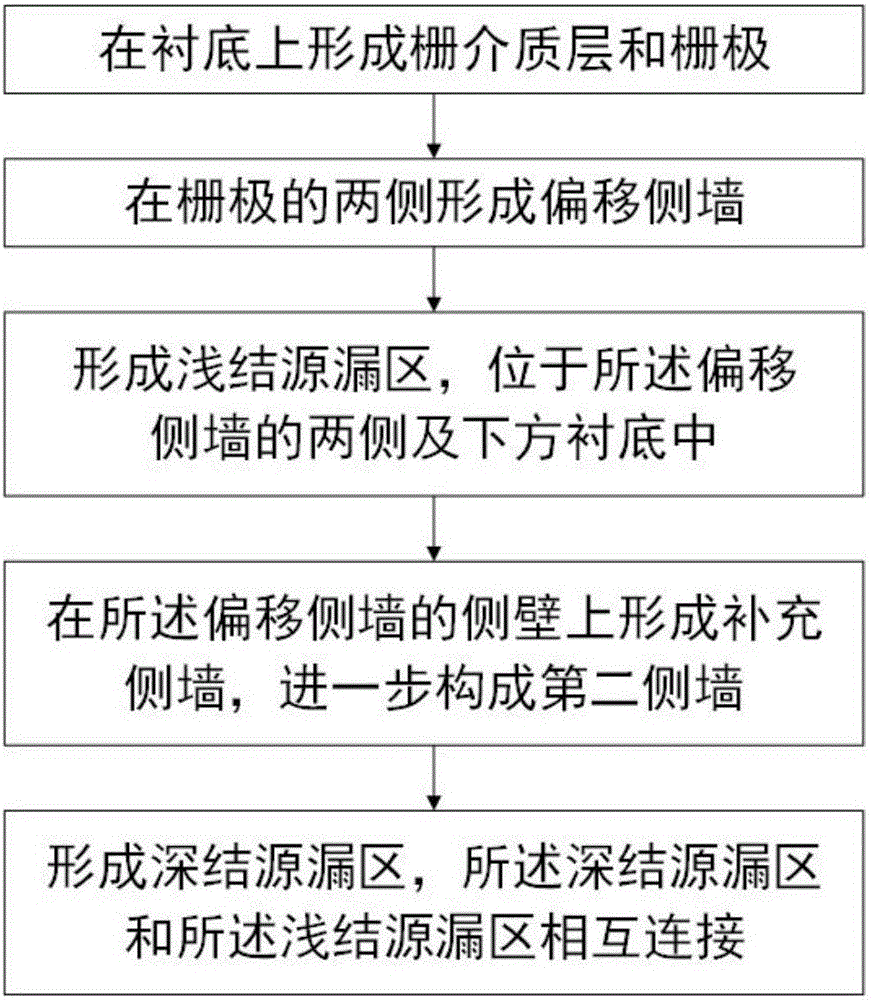

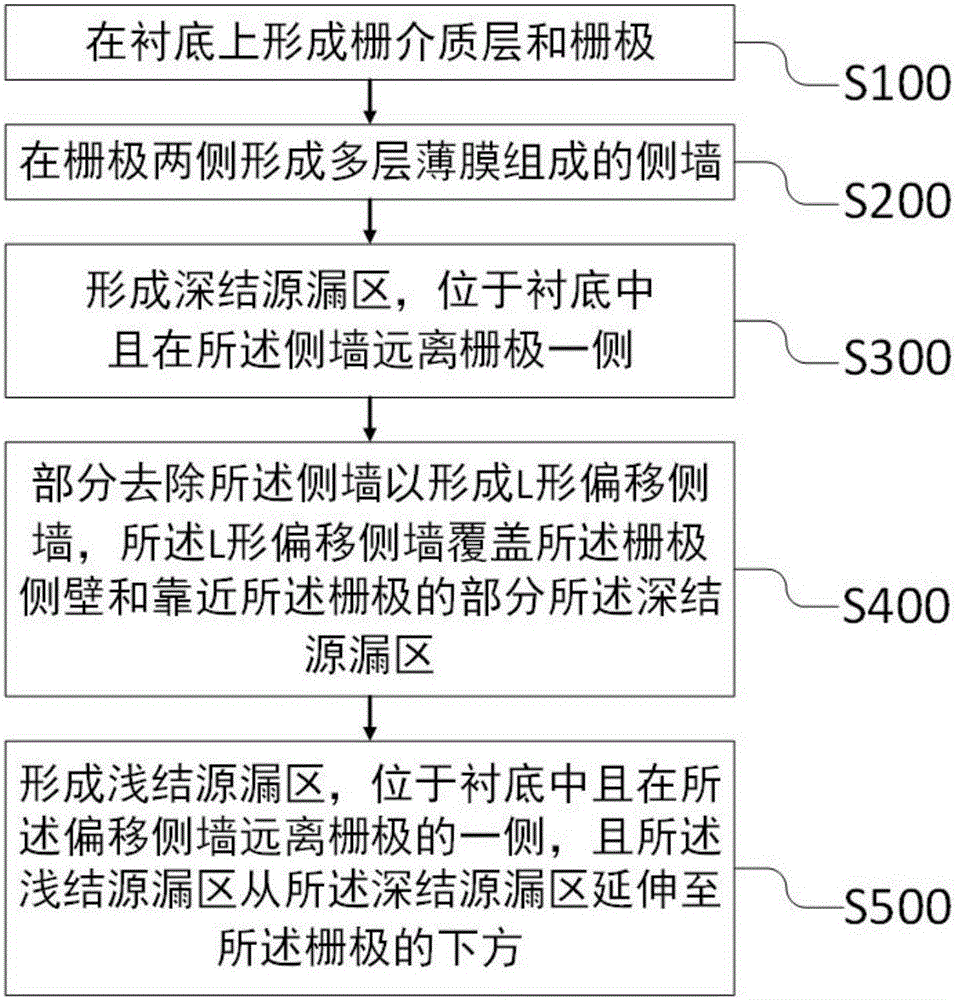

[0048] figure 2 It is a schematic flow diagram of the method for preparing a field effect transistor in Embodiment 1 of the present invention; Figure 3 to Figure 6 It is a structural schematic diagram of the method for manufacturing a field effect transistor in Embodiment 1 of the present invention during its preparation. The following reference figure 2 , image 3 , Figure 4 and Figure 5 , a specific embodiment of the present invention in detail, in this embodiment, the preparation method of the field effect transistor includes the following steps in sequence:

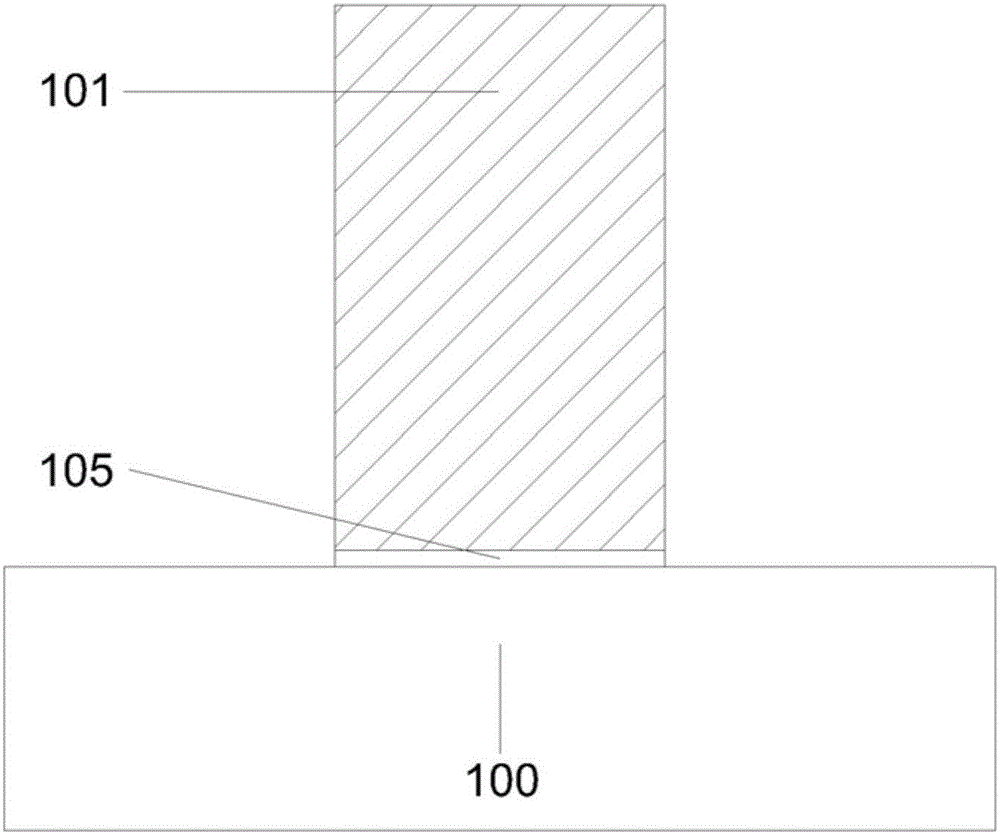

[0049] First, execute step S100, for details, refer to image 3As shown, a gate dielectric layer 105 and a gate 101 are formed on a substrate 100 , the gate 101 is formed on the gate dielectric layer 105 , and the substrate surface is exposed on both sides of the gate 101 . Optionally, the substrate 100 is a silicon substrate or a silicon germanium substrate, etc., the gate dielectric layer 105 is, for exam...

Embodiment 2

[0068] Figure 7 It is a schematic diagram of a partial structure during the preparation process of the field effect transistor preparation method in Example 2 of the present invention. combine Figure 5 and Figure 7 As shown, the difference from Embodiment 1 is that in this embodiment, the side wall adopts a two-layer structure. Therefore, the difference between the first embodiment and the second embodiment is mainly reflected in step S200 and step S400, therefore, only these two steps in this embodiment will be described in detail below.

[0069] Concrete combination figure 2 and Figure 7 As shown, in step S200 , during the process of forming sidewalls on both sides of the gate 101 , the structure of the formed sidewalls is a double-layer ON structure of silicon oxide layer 202 / silicon nitride layer 203 . The specific formation method can refer to the following steps: first, the silicon oxide layer 202 can be deposited by atomic layer deposition (Atomic Layer Depos...

Embodiment 3

[0072] Figure 8 It is a schematic diagram of the partial structure of the method for preparing the field effect transistor in the third embodiment of the present invention during its preparation process. combine Figure 7 and Figure 8 As shown, the difference from the second embodiment is that in this embodiment, the film layer in the sidewall close to the gate is a silicon oxide layer.

[0073] In this example, specific reference Figure 8As shown, in the step S200 , during the process of forming sidewalls on both sides of the gate 101 , the structure of the formed sidewalls is a double-layer NO structure of silicon nitride layer 302 / silicon oxide layer 303 . The specific formation method can refer to the following steps: first, the silicon nitride layer 302 can be deposited by atomic layer deposition (Atomic Layer Deposition, ALD) technology; then, silicon oxide can be deposited by chemical vapor deposition (Chemical Vapor Deposition, CVD) Layer 303, for example, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com