Desulfurization and denitrification mixed reaction device and desulfurization and denitrification integrated process

A desulfurization, denitrification, and reaction device technology, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems affecting desulfurization and denitrification efficiency, utilization of unflue gas waste heat, low decomposition rate, etc., and achieves compact structure. The effect of large land area and high equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

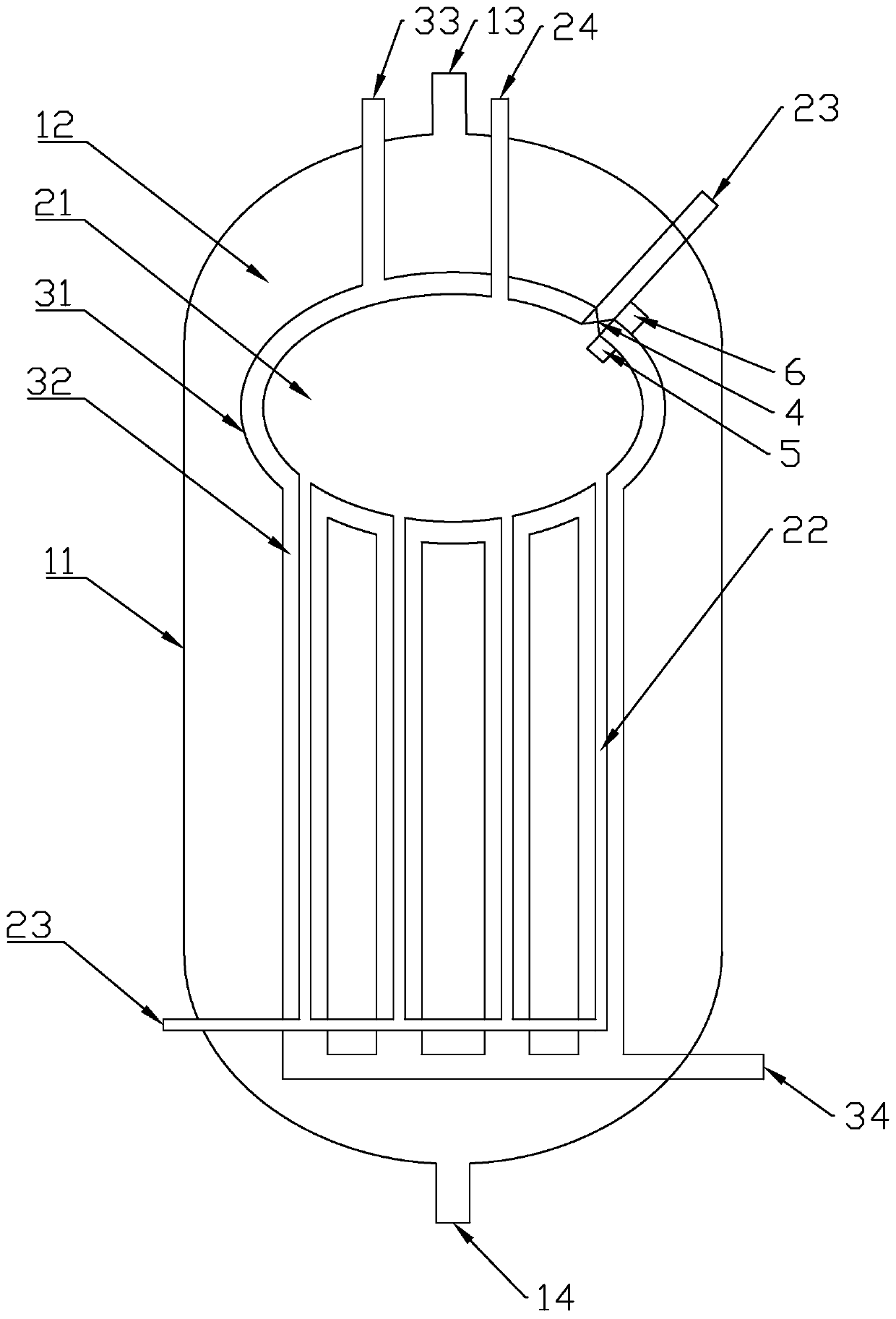

[0034]The present invention provides a desulfurization and denitrification mixed reaction device, which includes a device body 11, a reaction kettle 21 and at least one flue gas pipe 22 arranged inside the device body 11, and the device body 11 is provided with a The flue gas inlet 23, the flue gas outlet 24 and the ozone inlet 25, the reactor 21 communicates with the flue gas inlet 23 through the flue gas pipeline 22; The airtight casing 31 on the outside of the pipe 22, the shape of the casing 31 is consistent with the shape of the reaction kettle 21 and the flue gas pipeline 22, and an airtight second is formed between the casing 31 and the reaction kettle 21 and the flue gas pipeline 22. Cooling medium channel 32, the device body 11 is provided with a second cooling medium inlet 33 and a second cooling medium outlet 34 communicating with the second cooling medium channel 32; The first cooling medium passage 12, the device body 11 is also provided with a first cooling mediu...

Embodiment 2

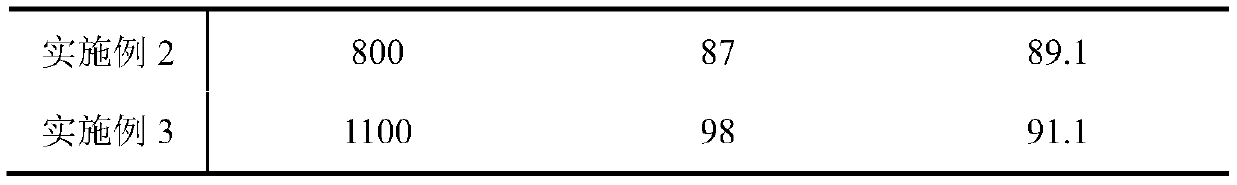

[0045] The mixed reaction device for desulfurization and denitrification provided in this embodiment is the same as in Example 1, except that the following content is changed: the length of the flue gas pipeline 22 is 7 times the height of the reactor 21, and the inner diameter of the flue gas pipeline 22 is 1 times the inner diameter of the reactor 21. / 10 times;

[0046] The desulfurization and denitrification integrated process provided in this embodiment is the same as that in Embodiment 1, except that the following content is changed: the first cooling medium is water, the second cooling medium is water, and the molar ratio of ozone and nitrogen oxides in the flue gas is 1.

Embodiment 3

[0048] The desulfurization and denitrification mixed reaction device provided in this embodiment is the same as that in Example 1, except that the following content is changed: the length of the flue gas pipeline 22 is 10 times the height of the reactor 21, and the inner diameter of the flue gas pipeline 22 is 1 times the inner diameter of the reactor 21. / 15 times.

[0049] The desulfurization and denitrification integrated process provided in this embodiment is the same as that in Embodiment 1, only the following content is changed: the first cooling medium is water, the second cooling medium is heat transfer oil, the ozone and the nitrogen oxide mole in the flue gas The ratio is 1.3.

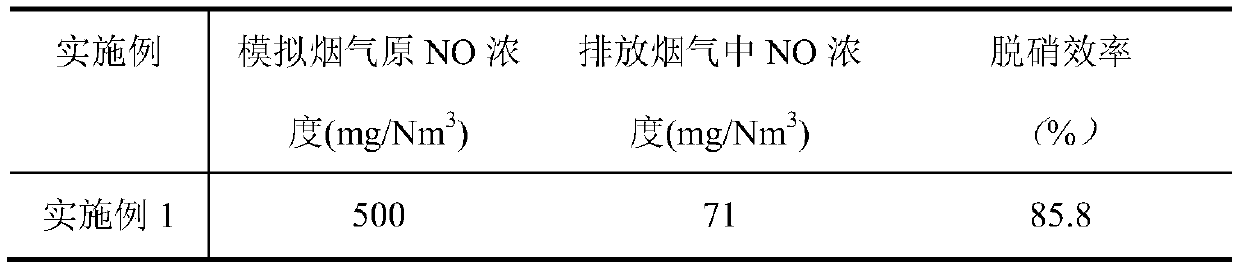

[0050] The desulfurization and denitrification mixed reaction devices of Examples 1 to 3 have the following effects in the desulfurization and denitrification integrated process (because the main form of nitrogen oxides in the flue gas is NO, the denitrification efficiency of the catalyst is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com