Extruded molecular sieve honeycomb catalyst and preparation method thereof

A honeycomb catalyst and molecular sieve technology, applied in molecular sieve catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of easy coating peeling, complicated preparation process and improvement, achieve good De-NOx activity, overcome coating problems, etc. Layer shedding, high efficiency load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

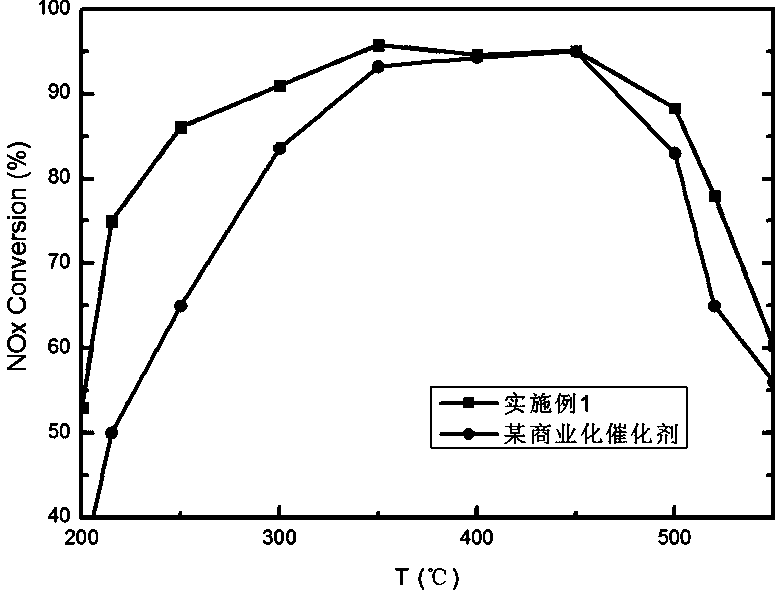

Embodiment 1

[0017] The first step: the preparation of mud

[0018] Put 5.5kg of kaolin, 2.0kg Beta25 molecular sieve, 0.5kg of mullite fiber, 2.0kg of aluminum dihydrogen phosphate, 0.3kg of methylcellulose, 0.3kg of tung oil, 0.3kg of glycerin and 2kg of water into a kneader for 4h. Mud; put the mud in a vacuum mud mixer for smelting, and the mixing time is 4h; after that, wrap the mud after vacuum smelting with plastic wrap and put it in a cool and humid air for 20 hours to age. Get good plasticity;

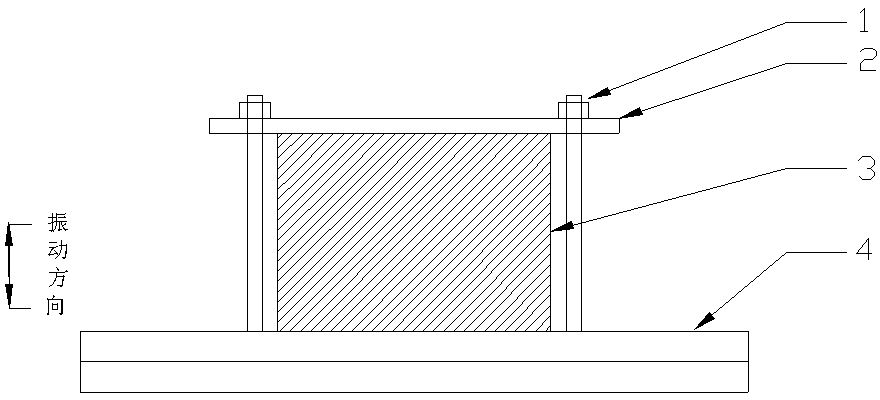

[0019] Step 2: Setting the honeycomb ceramic body

[0020] Put the stale mud blank into the extruder for extrusion molding, the extrusion pressure is 23Mpa, the mud blank is passed through a stainless steel mold with a bottom diameter of 18cm and 200 mesh, and then cut into the required length of honeycomb ceramic wet with molybdenum wire Green body: After the green body is extruded, it is quickly put into the microwave for drying and shaping, the drying temperature is 105℃, until it is dry, th...

Embodiment 2

[0026] The first step: the preparation of mud

[0027] Put 5.5kg kaolin, 1.7kg Sapo-34 molecular sieve, 0.3kg mullite fiber, 2.5kg glass powder, 0.4kg hydroxypropyl methylcellulose, 0.3kg tung oil, 0.3kg glycerin and 2.5kg water into the kneader After mixing for 8 hours into mud; then put the mud in a vacuum mud mixer for mixing, and the mixing time is 1 hour; then wrap the mud after vacuum mud mixing with plastic wrap and put it in cool and humid air It is aged for 24 hours, and the plastic body is prepared;

[0028] Step 2: Setting the honeycomb ceramic body

[0029] Put the stale mud blank into the extruder for extrusion molding, the extrusion pressure is 23Mpa, the mud blank is passed through a stainless steel mold with a bottom diameter of 18cm and 200 mesh, and then cut into the required length of honeycomb ceramic wet with molybdenum wire Green body: After being extruded, the green body is quickly placed in a microwave at 105°C for drying and setting, until it dries out, the...

Embodiment 3

[0033] The first step: the preparation of mud

[0034] Put 6kg attapulgite, 0.8kg SSZ-13 molecular sieve, 0.2kg mullite fiber, 3.0kg silica sol, 0.3kg hydroxyethyl cellulose, 0.3kg tung oil, 0.3kg glycerin and 0.5kg water into the kneader Mix the mud for 4h; then put the mud in a vacuum mud mixer for mud refining for 2h; then wrap the mud after vacuum mud refining with plastic wrap and put it in a cool and humid air for 20 hours to aging to obtain plasticity Good mud

[0035] Step 2: Setting the honeycomb ceramic body

[0036] Put the stale mud blank into the extruder for extrusion molding, the extrusion pressure is 23Mpa, the mud blank is passed through a stainless steel mold with a bottom diameter of 18cm and 200 mesh, and then cut into the required length of honeycomb ceramic wet with molybdenum wire Green body: After the green body is extruded, it is quickly placed in the microwave at 110°C for drying and shaping, until it is dry, the end surface is processed; 580°C, sintered f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com