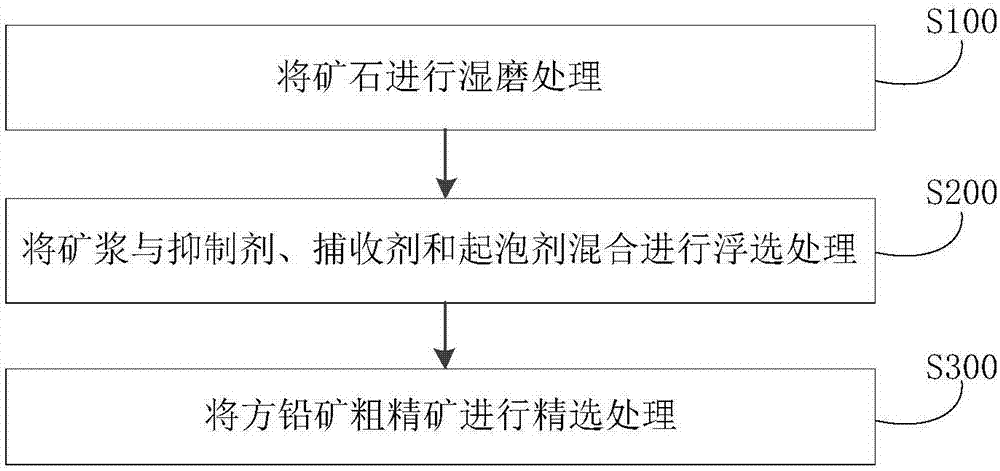

Method for separating lead concentrate from ore

A technology for separating lead and ore, which is applied in solid separation, flotation, etc., and can solve the problems affecting the recovery rate of galena, large consumption, and many types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In a lead-zinc mine in Inner Mongolia, the lead rough concentrate ore contains 14.96wt% Zn, 25.44wt% Pb, and 40.22% pyrite. The ore is mixed with water, and the ore mixed with water is sent to a ball mill for ball milling. , to obtain an ore pulp with a mass concentration of 25wt% and a particle size of not more than 0.074 mm, accounting for 50-90%; then first mix and stir sodium thioglycolate and the ore pulp according to a mass ratio of 15:100000, and stir for 2-6 minutes to obtain the first mixed After the liquid, the collector ethiazide, the foaming agent terpineol oil and the first mixed liquid were mixed and stirred according to the mass ratio of 2:1.5:100000, and stirred for 2-6 minutes to obtain the second liquid with a pH value of 5.0-12.0. The second mixed liquid is then subjected to flotation for 3-10 minutes to obtain galena rough concentrate and tailings; finally, the galena rough concentrate is subjected to secondary concentration to obtain lead concentrate...

Embodiment 2

[0039] In a copper-lead-zinc mine in Canada, the lead rough concentrate ore contains 16.57wt% Zn, 12.36wt% Pb, and 51.12% pyrite. The ore is mixed with water, and the ore mixed with water is sent to a ball mill for ball milling treatment to obtain a pulp with a mass concentration of 33wt% and a particle size of no more than 0.074 mm, accounting for 50-90%; then first mix and stir sodium thioglycolate and the pulp according to a mass ratio of 12:100000, and stir for 2-6 minutes to obtain the first Mix the liquid, then mix and stir the collector xanthate, foaming agent methyl isobutyl carbinol and the first mixed liquid according to the mass ratio of 8:4:100000, stir for 2-6min, and obtain a pH value of 5.0- 12.0 of the second mixed liquid, and then flotation the second mixed liquid for 3-10 minutes to obtain galena coarse concentrate and tailings; finally, the galena coarse concentrate is subjected to three times of beneficiation to obtain lead concentrate . The grade of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com