Novel magnetic sealing material and preparation method thereof

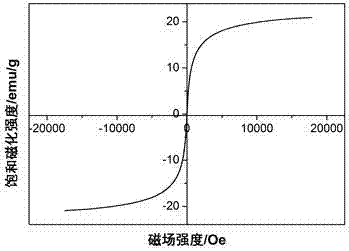

A sealing material and magnetic technology, applied in the direction of magnetic materials, magnetic objects, magnetic liquids, etc., can solve the problems of magnetic sealing parts that cannot meet the sealing requirements, poor stability, settlement, etc., and achieve good magnetic sealing effect and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

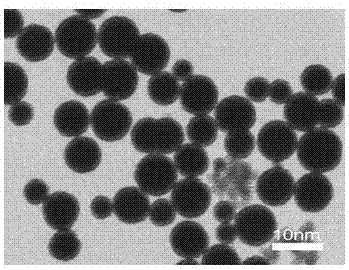

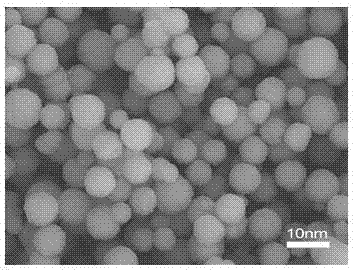

[0025] Silica-coated perfluorooctanoic acid-grafted Fe3O4 magnetic nanoparticles. Take 27.8g ferrous sulfate heptahydrate and 3.99g ferric chloride to prepare 50mL solution, then add 200mL ammonia solution (100mL concentrated ammonia water and 100mL deionized water), and mechanically stir at 300rpm for 2h. The mixture is then transferred to a beaker, and the beaker is placed above the magnet, so that the ferroferric oxide magnetic nanoparticles are quickly precipitated to the bottom of the beaker, the water and impurities in the upper part are poured off, and the deionized water is used to clean 2-3 times to obtain High-purity ferroferric oxide magnetic nanoparticles; disperse the ferroferric oxide magnetic nanoparticles into a mixed solution formed by 100mL ethanol and 200mL deionized water, stir at 50°C at a rate of 300rpm for 15min and then at 50°C Add 30mL of concentrated ammonia water, add 20g of tetraethyl orthosilicate after another 20min, add 0.5g of aminopropyltrimeth...

Embodiment 2

[0027]Silica-coated perfluorohexanoic acid-grafted ferroferric oxide magnetic nanoparticles. Take 27.8g ferrous sulfate heptahydrate and 3.99g ferric chloride to prepare 50mL solution, then add 200mL ammonia solution (100mL concentrated ammonia water and 100mL deionized water), and mechanically stir at 300rpm for 2h. Then transfer the mixture to a beaker, and place the beaker above the magnet, so that the magnetic ferroferric oxide quickly settles to the bottom of the beaker, pour off the upper water and impurities, and use deionized water to wash 2-3 times to obtain high purity Fe3O4 nanoparticles. Disperse the ferroferric oxide magnetic nanoparticles into the mixed solution formed by 100mL ethanol and 200mL deionized water, add 30mL concentrated ammonia water after stirring at a rate of 300rpm for 15min, add 20g tetraethyl orthosilicate after another 20min, and react After 1 hour, add 0.5 g of aminopropyltrimethoxysilane to the system, keep the stirring rate and reaction te...

Embodiment 3

[0029] Silica-coated ferric oxide magnetic nanoparticles grafted with fluoroether acid. Take 27.8g ferrous sulfate heptahydrate and 3.99g ferric chloride to prepare 50mL solution, then add 200mL ammonia solution (100mL concentrated ammonia water and 100mL deionized water), and mechanically stir at 300rpm for 2h. Then transfer the mixture to a beaker, and place the beaker above the magnet, so that the magnetic ferroferric oxide quickly settles to the bottom of the beaker, pour off the upper water and impurities, and use deionized water to wash 2-3 times to obtain high purity Fe3O4 magnetic nanoparticles. Disperse the ferroferric oxide magnetic nanoparticles into a mixed solution formed by 100mL ethanol and 200mL deionized water, stir at 50°C at a rate of 300rpm for 15min, add 30mL of concentrated ammonia water, and add 20g of orthosilicate tetrachloride after another 20min. Ethyl ester, after reacting for 1 hour, add 0.5 g of aminopropyltrimethoxysilane to the system, keep the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com