A kind of anti-protein adsorption capillary column and preparation method thereof

An anti-protein adsorption and capillary column technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of complex preparation process, high toxicity in the production process, harsh operating conditions, etc., and achieve simple and fast preparation process, excellent anti-protein The effect of adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

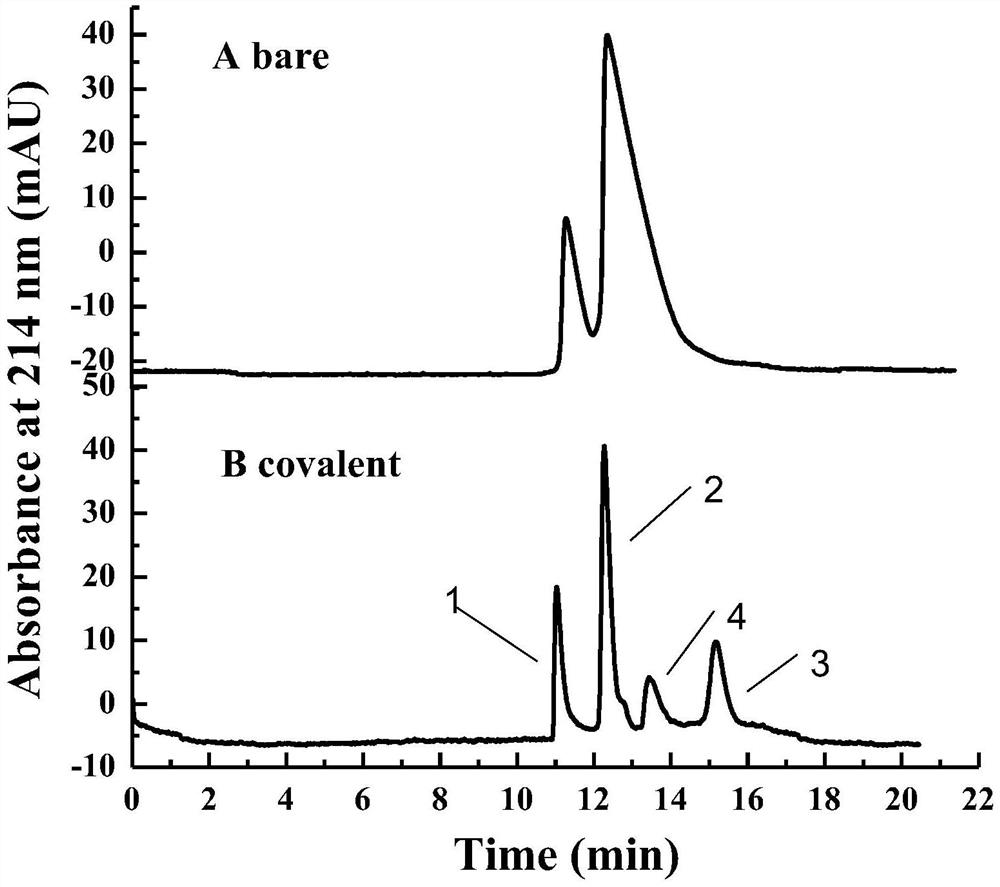

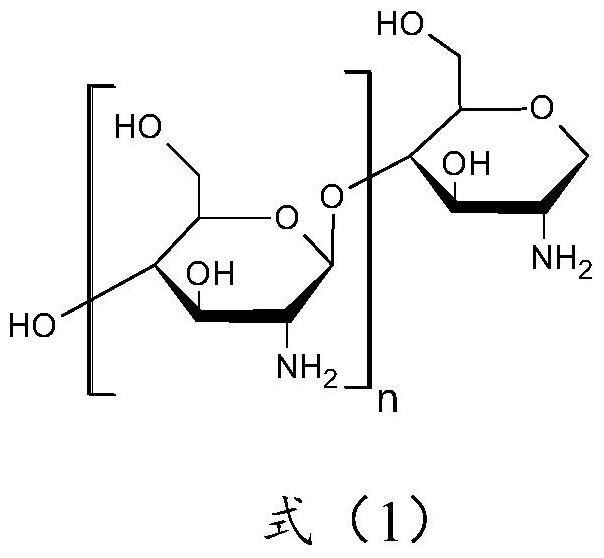

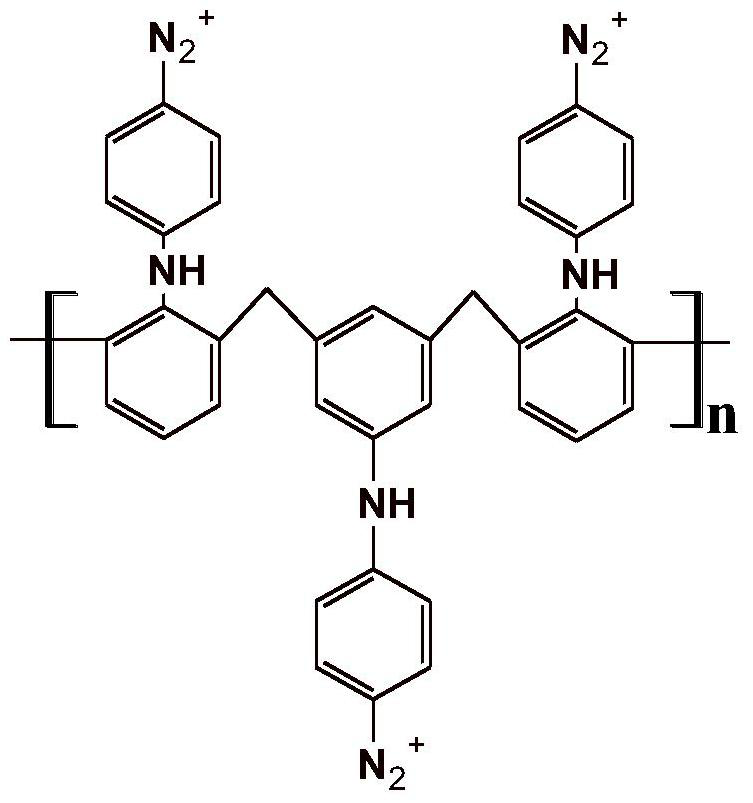

[0028] The preparation method of the above-mentioned anti-protein adsorption capillary column uses diazo resin and carboxylated chitosan to self-assemble layer by layer on the inner wall of the quartz capillary column through electrostatic interaction, and undergoes a photocuring cross-linking reaction under ultraviolet light to make the original hydrogen The bonds are converted to covalent bonds, thereby forming a stable covalently bonded coating on the inner wall of the quartz capillary. Specifically, the preparation method comprises the following steps:

[0029] S1, the concentration is 0.05-500mg·ml -1 Photosensitive diazo resin solution, water, concentration 0.05-500mg·ml -1 The carboxylated chitosan aqueous solution and water are slowly injected into the capillary successively; the mass ratio of the photosensitive diazo resin to the carboxylated chitosan aqueous solution is 1:1.

[0030] The concentrations of the above-mentioned diazo resin and carboxylated chitosan aq...

Embodiment 1

[0046] This implementation provides a preparation method for an anti-protein adsorption capillary column, including the following steps:

[0047] S0, capillary internal activation pretreatment

[0048] successively with a concentration of 0.1mol·L -1 Sodium hydroxide solution, distilled water, the concentration is 0.1mol L -1 Flush the capillary with hydrochloric acid solution, distilled water and methanol for 30min, 10min, 30min, 10min and 10min respectively, and then use N 2 The activated capillary can be obtained by drying the capillary.

[0049] S1. At a temperature of 25°C, use a concentration of 0.1 mg·ml -1 The photosensitive diazo resin solution (molecular weight 1000) rinses the capillary column for 10 minutes, and distilled water rinses the capillary column for 2 minutes. Then use a concentration of 0.5mg·ml -1 Carboxylated chitosan aqueous solution (weight-average molecular weight 150000) washes the capillary column for 10 minutes, and then uses distilled water...

Embodiment 2

[0053] This implementation provides a preparation method for an anti-protein adsorption capillary column, including the following steps:

[0054] S0, capillary internal activation pretreatment

[0055] successively with a concentration of 0.09mol·L -1 Sodium hydroxide solution, distilled water, the concentration is 0.11mol L -1 Flush the capillary with hydrochloric acid solution, distilled water and methanol for 35min, 8min, 35min, 8min and 8min respectively, and then use N 2 The activated capillary can be obtained by drying the capillary.

[0056] S1. At a temperature of 25°C, the concentration is 100mg·ml -1 The photosensitive diazo resin solution (weight average molecular weight 5500) washes the capillary column for 10 minutes, distilled water washes the capillary column for 2 minutes, and then washes the capillary column with a concentration of 100mg·ml -1 Carboxylated chitosan aqueous solution (weight-average molecular weight 200000) washes the capillary column for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com