Transformer oil fire extinguishing agent

A technology for transformers and fire extinguishing agents, applied in fire protection equipment and other directions, can solve problems such as damage to electrical equipment, reduce flash point, and long duration, and achieve the effects of safe and reliable use, improved practical performance, and strong extinguishing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

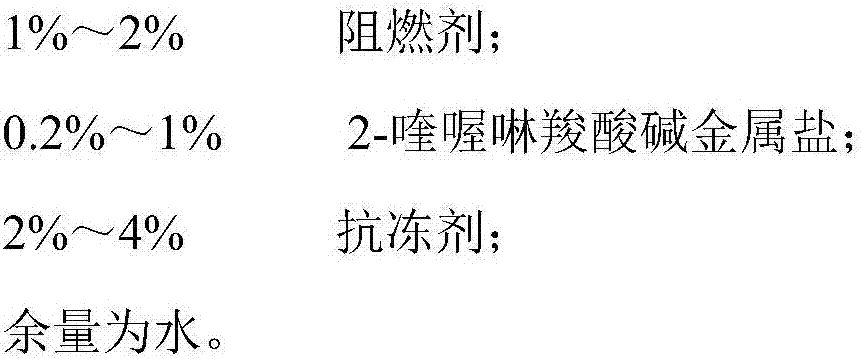

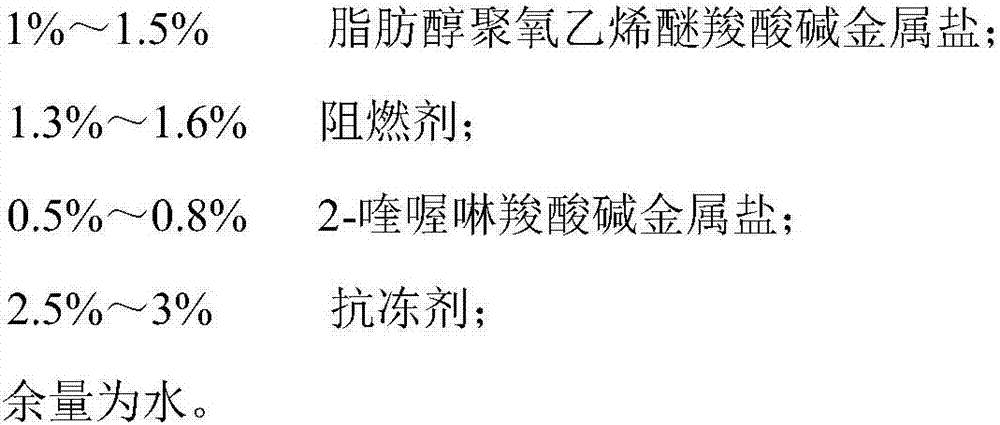

Method used

Image

Examples

Embodiment 1

[0033] Weigh 1kg of potassium 2-quinoxaline carboxylate, 4kg of ethylene glycol, 0.1kg of fluorescent dye, and 92.8kg of water, respectively, and stir uniformly in the reaction kettle for 1 hour. Then weigh 0.1 kg sodium fatty alcohol polyoxyethylene ether carboxylate, add 2 kg ammonium bicarbonate into the reaction kettle, and stir for 1 hour to obtain sample 1.

Embodiment 2

[0035] Weigh 0.2kg of potassium 2-quinoxaline carboxylate, 2kg of ethylene glycol, 0.05kg of fluorescent dye, and 94.75kg of water, respectively, and stir uniformly in the reaction kettle for 1 hour. Then weigh 2 kg of sodium fatty alcohol polyoxyethylene ether carboxylate, add 1 kg of ammonium bicarbonate into the reaction kettle, and stir for 1 hour to obtain sample 2.

Embodiment 3

[0037] Weigh 0.5kg of potassium 2-quinoxaline carboxylate, 2.5kg of ethylene glycol, 0.1kg of fluorescent dye, and 94.6kg of water, respectively, and stir uniformly in the reaction kettle for 1 hour. Then weigh 1 kg sodium fatty alcohol polyoxyethylene ether carboxylate, add 1.3 kg ammonium bicarbonate into the reaction kettle, and stir for 1 hour to obtain sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com