Slag removing mechanism for PCB hole

A technology for PCB boards and pallets, applied in the field of PCB board hole slag removal mechanism, can solve problems such as poor environmental protection of slag, achieve good removal effect, prevent secondary adhesion, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

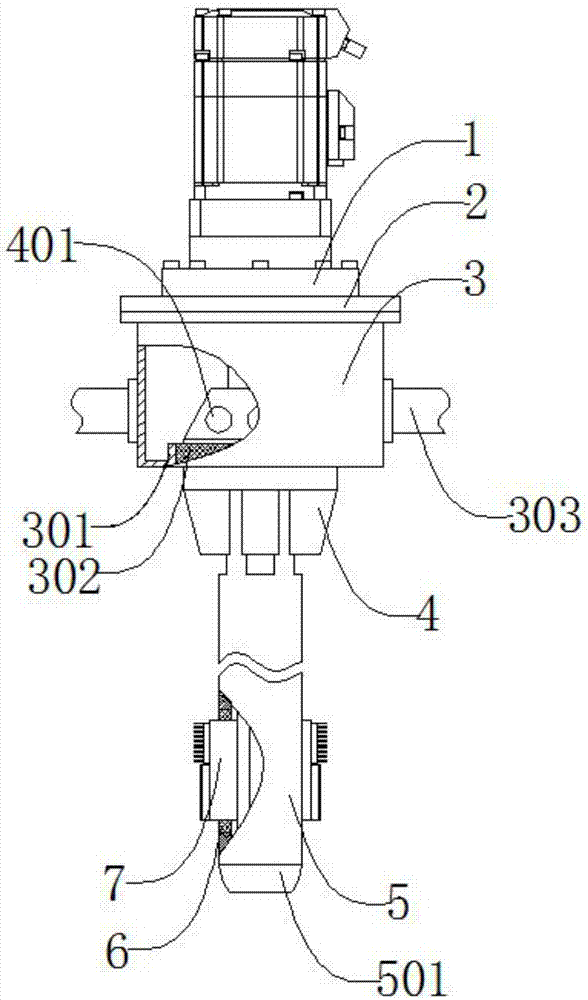

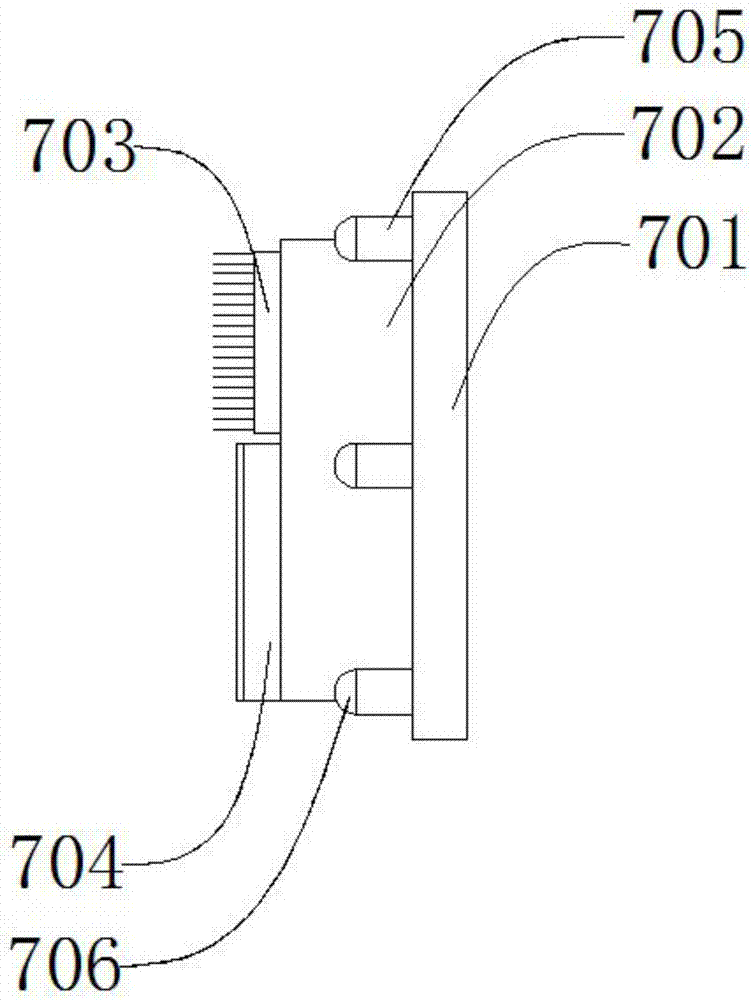

[0028] like figure 1 , figure 2 As shown, a PCB board hole slag removal mechanism includes a motor 1, a supporting plate 2, a bellows 3, a chuck 4, a hollow sleeve 5, and two spacer sleeves 6 symmetrically arranged along the hollow sleeve 5. , drill mechanism 7, described supporting plate 2 is positioned at motor 1 lower end, and described supporting plate 2 is connected with motor 1 screw thread, and described bellows 3 is positioned at supporting plate 2 lower ends, and described bellows 3 is threaded with supporting plate 2 connected, the chuck 4 is located at the lower end of the motor 1 and runs through the bellows 3, the chuck 4 is threadedly connected with the motor 1 and is movably connected with the bellows 3, the hollow sleeve 5 is located at the lower end of the chuck 4, the The hollow casing 5 is threadedly connected with the collet 4, the spacer sleeve 6 is embedded in the pipe wall of the hollow casing 5, the spacer sleeve 6 is closely connected with the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com