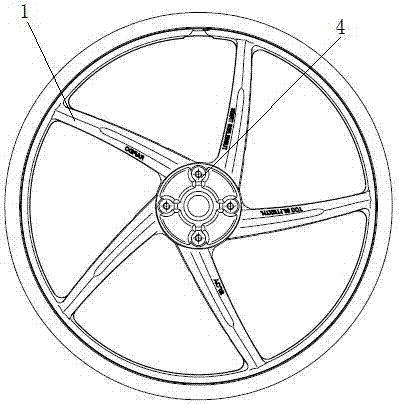

Production process for motorcycle wheel hub

A production process and technology for motorcycles, applied in the direction of wheels, wheels made of non-metallic materials, vehicle parts, etc., can solve the problems of poor surface quality, dim product valve hole position, high baking temperature, and achieve improved effect and appearance. Quality, effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: motorcycle hub production process, comprises the following steps:

[0041] 1) Melting and composition analysis: the raw material aluminum ingots and other additives are heated through natural gas to form aluminum water, after degassing, slag removal, and refining treatment, the temperature is controlled between 680-720°C to prepare qualified casting aluminum water. The raw materials include A00 Aluminum ingot, silicon, magnesium, titanium and auxiliary materials, the specific ratio is: aluminum ingot 93.5%, silicon 6%, magnesium 0.2%, iron 0.2%, titanium 0.003%, other auxiliary materials 0.097%, the process is through natural gas furnace, crucible, In the pellet furnace, refining agent and slag removal agent are added during the smelting process. These two are auxiliary materials to ensure the qualified aluminum liquid and improve the effect of solution smelting; this step requires composition testing: the composition test is to use the M5000 direct-reading...

Embodiment 2

[0062] Embodiment 2: Different from Embodiment 1:

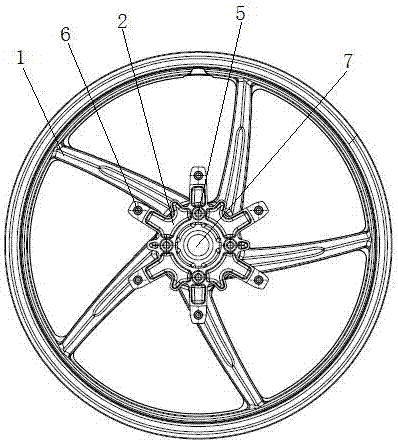

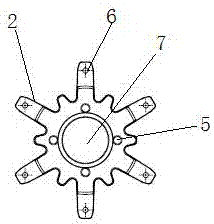

[0063] The aluminum sheet structure 2 3 in step (10) is different from that in Example 1. It is the front wheel hub of another car model with 5 disc brake holes 6 in the periphery, and the middle is also processed to match the shape of the aluminum sheet structure 1 2 The hole 7 is the same, but the matching hole 7 of different size is processed in the same way, and the aluminum sheet structure that completely matches the processing drawing is processed, and the positioning hole 4 in the center is assembled with the mounting hole 5 of the basic wheel hub to realize the second model. wheel production and processing.

[0064] The present invention only cites the above two embodiments to illustrate the improvement of the present invention. Through the above embodiments, the purpose of processing three pairs of front wheels on one mold can be realized. The basic wheel hub is also a separate one during actual production. For the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com