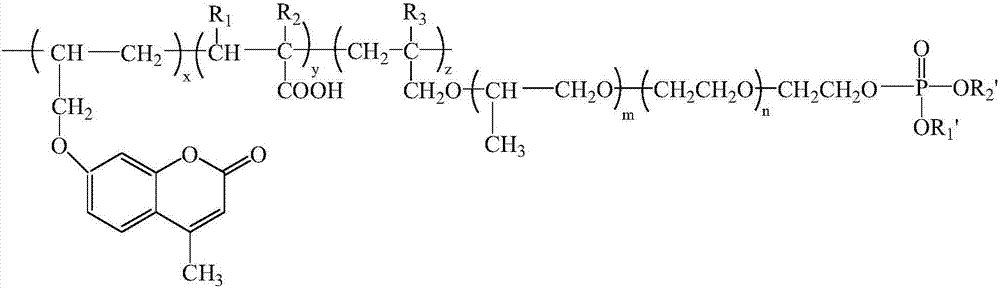

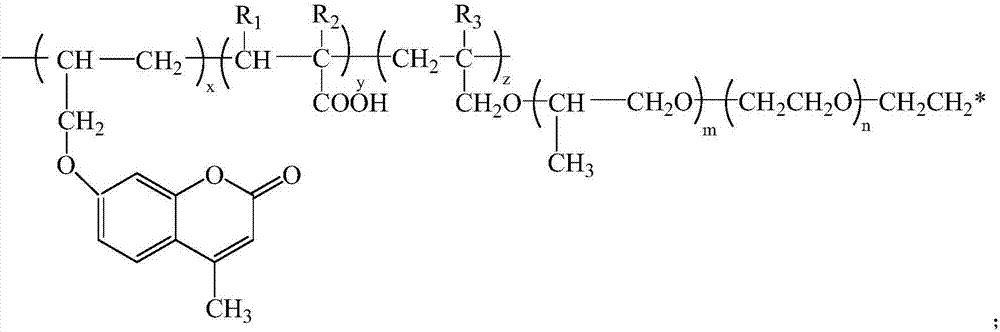

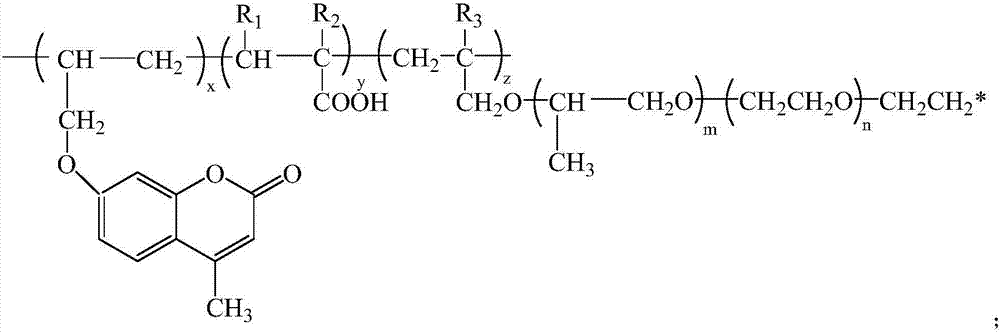

Phosphorus spectrum and fluorescent double tracer polycarboxylate superplasticizer and preparation method thereof

A technology of double tracer and polycarboxylate, which is applied in the field of phosphorus spectrum, fluorescent double tracer polycarboxylate water reducer and its preparation, to achieve the effect of good hydrophilicity and dispersion performance, high practical performance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Example 1: In a dry four-necked flask equipped with a stirrer, a reflux condenser and a thermometer, under N 2 Under atmosphere, put 600g of allyl polyethylene glycol monoether with ethyleneoxy polymerization degree n of 45 and average molecular weight of 2000 into a flask, heat to 40°C and melt, then add 35g of anhydrous orthophosphoric acid and allylpolyethylene glycol monoether Mix ethylene glycol monoether, heat up to 55°C under rapid mechanical stirring, react with temperature control for 3.5 hours, then cool to room temperature to obtain light yellow transparent viscous liquid allyl polyethylene glycol monoether phosphate monomer. Weigh 210g above-mentioned allyl polyethylene glycol monoether phosphate monomer and dissolve in 20g distilled water, pour in the flask and stir; 2Add 36g of acrylic acid (dissolved in 100g of distilled water) and 5g of sodium superphosphate (dissolved in 25g of distilled water) and 4.36g of 7-allyloxy-4-methylcoumarin at the same time d...

example 2

[0033] Example 2: In a dry four-necked flask equipped with a stirrer, a reflux condenser and a thermometer, under N 2 Under atmosphere, put 600g of allyl polyethylene glycol monoether with ethyleneoxy polymerization degree n of 45 and average molecular weight of 2000 into a flask, heat to 40°C and melt, then add 35g of anhydrous orthophosphoric acid and allylpolyethylene glycol monoether Mix ethylene glycol monoether, heat up to 55°C under rapid mechanical stirring, react with temperature control for 3.5 hours, then cool to room temperature to obtain light yellow transparent viscous liquid allyl polyethylene glycol monoether phosphate monomer. Weigh 210g above-mentioned allyl polyethylene glycol monoether phosphate monomer and dissolve in 20g distilled water, pour in the flask and stir; 2 Atmosphere and mechanical stirring, at 70°C, use a peristaltic pump to add dropwise 42g methacrylic acid (dissolved in 100g distilled water) and 5g sodium superphosphate (dissolved in 25g dis...

example 3

[0034] Example 3: In a dry four-necked flask equipped with a stirrer, a reflux condenser and a thermometer, under N 2 Under atmosphere, put 460g of allyl polyethylene glycol monoether with ethyleneoxy polymerization degree n of 52 and average molecular weight of 2300 into a flask, heat to 35°C and melt, then add 22g of anhydrous phosphoric acid and allyl polyethylene Mix glycol monoether, heat up to 50°C under rapid mechanical stirring, react at a controlled temperature for 3.5 hours, then cool to room temperature to obtain light yellow transparent viscous liquid allyl polyethylene glycol monoether phosphate monomer. Weigh again the allyl polyethylene glycol monoether phosphate monomer that 240g above-mentioned making is dissolved in 20g distilled water, pour in the flask and stir; 2 Atmosphere, mechanical stirring, at 65°C, use a peristaltic pump to add 36g of acrylic acid (dissolved in 100g of distilled water) and 5g of potassium persulfate (dissolved in 40g of distilled wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com