Polybutylene succinate ionomer with low molecular weight and high melt viscosity and its preparation and microcellular foaming material based on it and its application

A technology of polybutylene succinate and low molecular weight, which is applied in the field of microcellular foaming materials, polybutylene succinate ionomer and its preparation, and can solve the problem of difficult processing and difficult control of hexamethylene The amount of base diisocyanate, easy to produce cross-linking and other problems, to achieve high foaming ratio, easy control of cell size, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

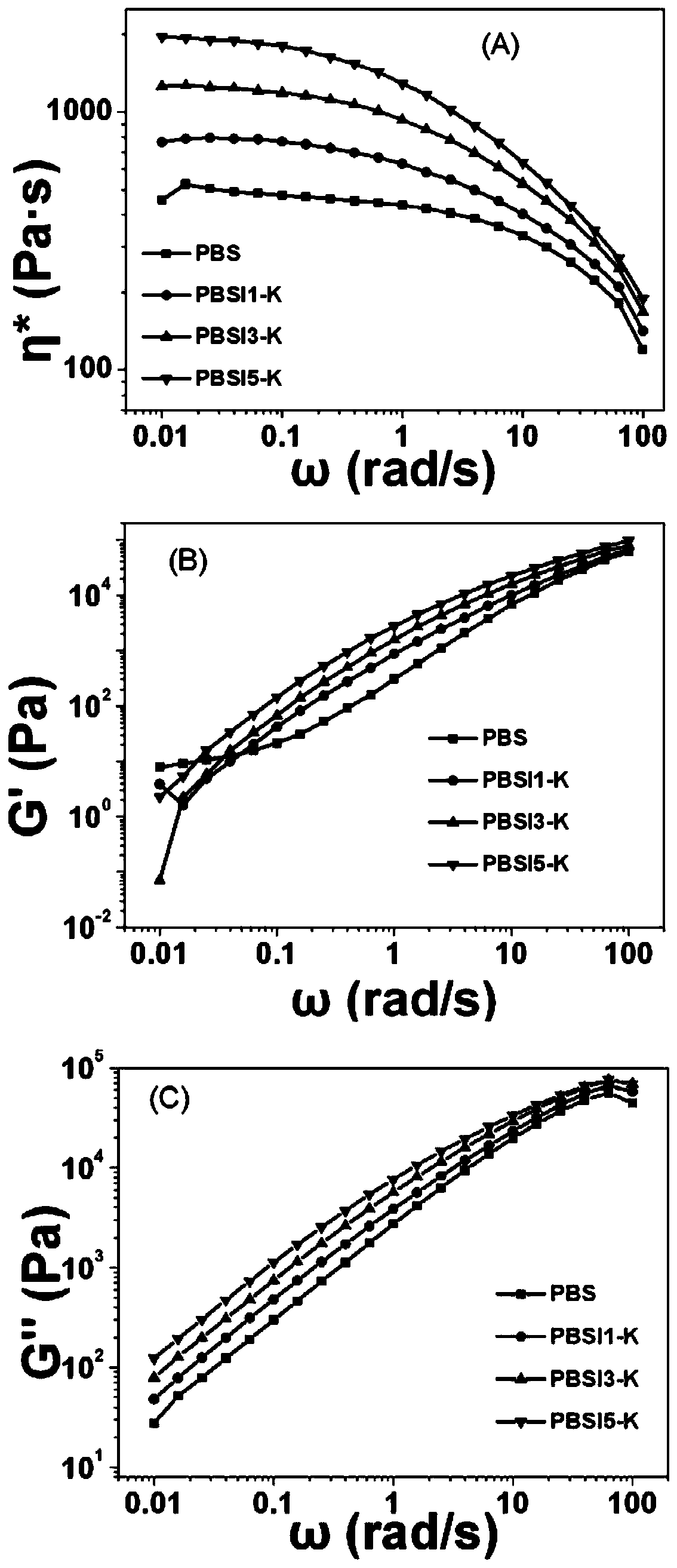

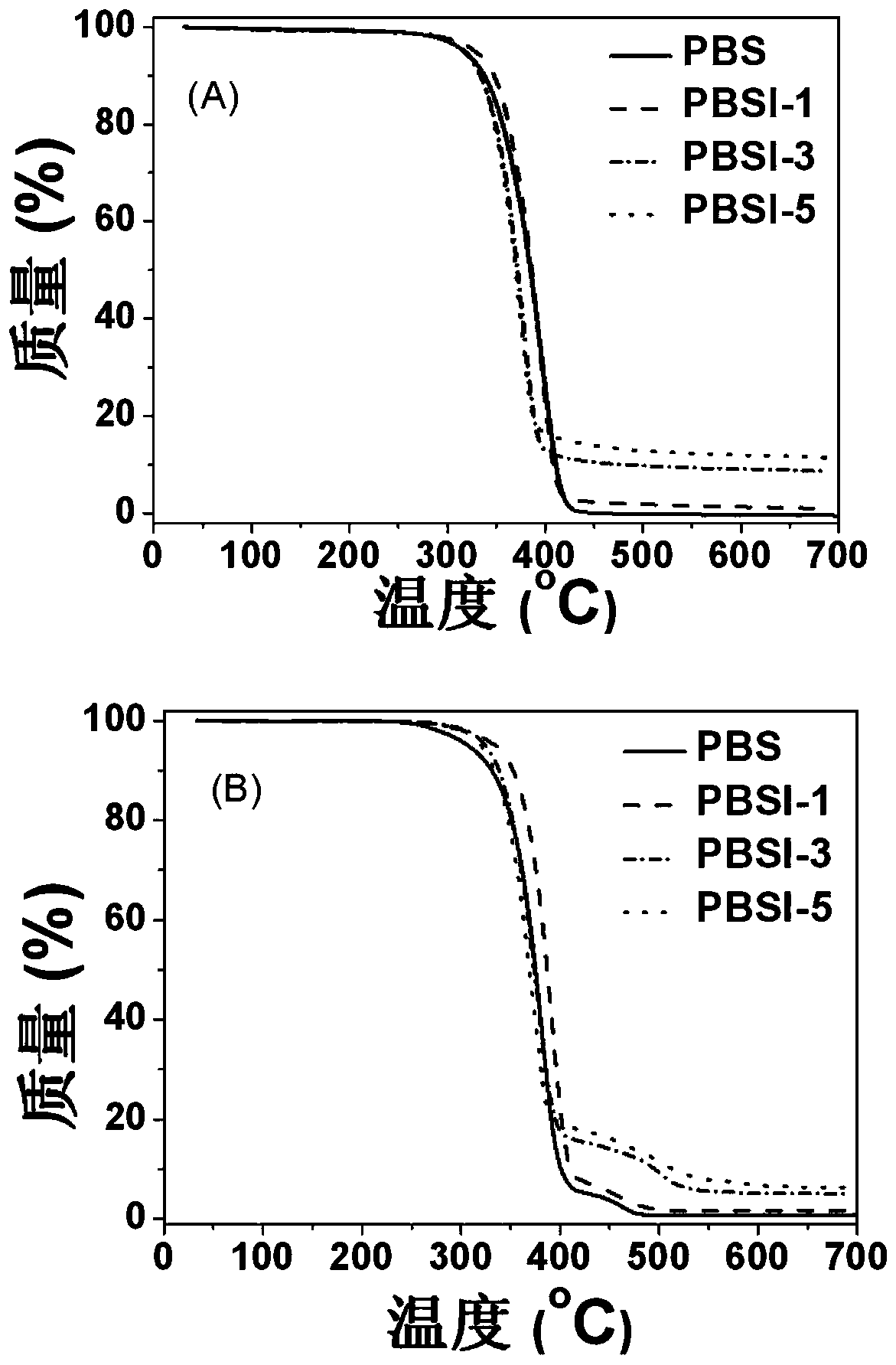

Embodiment 1

[0056] Succinic acid (SA, 1 mole part), butanediol (BD, 1.2 mole parts) and tetrabutyl titanate (100 ppm, as a catalyst) are mixed, and dry nitrogen is passed into the flask before esterification to replace the The air in the bottle was repeated 5 times to remove the air in the bottle. The system was under the protection of nitrogen, and then the system was heated up to 140-180°C under stirring, and the temperature was maintained until the collected by-product water was close to the theoretical value. After the reaction temperature rose As high as 210-250°C, about 2-4 hours. Then add a butanediol solution containing 0.01 mole parts of DHPPO-K, react for 10 minutes under nitrogen protection, and start vacuuming the system, and react for 4 to 10 hours to obtain PBSI1-K. The viscosity-average molecular weight tested is listed in Table 1.

Embodiment 2

[0058] Succinic acid (SA, 1 mole part), butanediol (BD, 1.2 mole parts) and tetrabutyl titanate (100 ppm, as a catalyst) are mixed, and dry nitrogen is passed into the flask before esterification to replace the The air in the bottle was repeated 5 times to remove the air in the bottle. The system was under the protection of nitrogen, and then the system was heated up to 140-180°C under stirring, and the temperature was maintained until the collected by-product water was close to the theoretical value. After the reaction temperature rose As high as 210-250°C, about 2-4 hours. Then add a butanediol solution containing 0.03 mole parts of DHPPO-K, react for 10 minutes under the protection of nitrogen, and start vacuuming the system, and react for 4 to 10 hours to obtain PBSI3-K. The viscosity-average molecular weight tested is listed in Table 1.

Embodiment 3

[0060] Succinic acid (SA, 1 mole part), butanediol (BD, 1.2 mole parts) and tetrabutyl titanate (100 ppm, as a catalyst) are mixed, and dry nitrogen is passed into the flask before esterification to replace the The air in the bottle was repeated 5 times to remove the air in the bottle. The system was under the protection of nitrogen, and then the system was heated up to 140-180°C under stirring, and the temperature was maintained until the collected by-product water was close to the theoretical value. After the reaction temperature rose As high as 210-250°C, about 2-4 hours. Then add a butanediol solution containing 0.05 mole parts of DHPPO-K, react for 10 minutes under the protection of nitrogen, and start vacuuming the system, and react for 4 to 10 hours to obtain PBSI5-K. The viscosity-average molecular weight tested is listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com