Ion exchange eluting column for compact moving bed

A dense moving bed and ion exchange technology, applied in the direction of improving process efficiency, can solve the problems of difficult distribution of material and liquid, large equipment and civil construction investment costs, and reduced filter area of filter tubes, etc. The effect of reducing frequent valve operation and reducing automation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

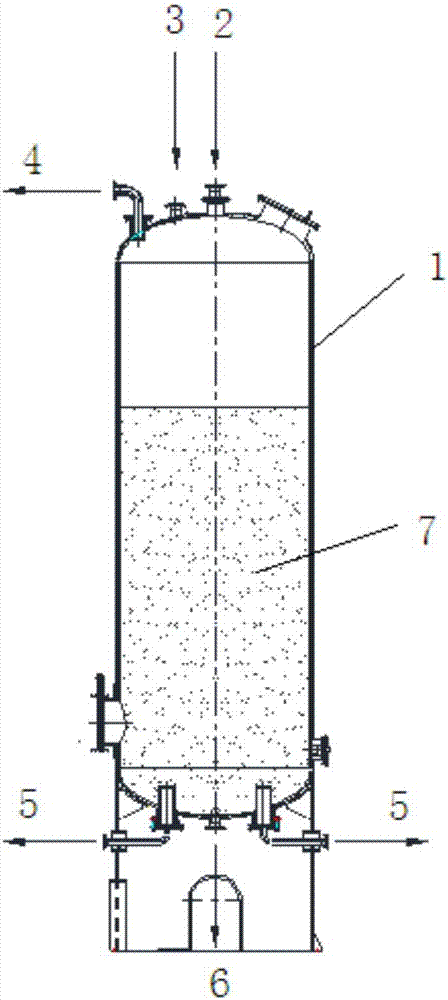

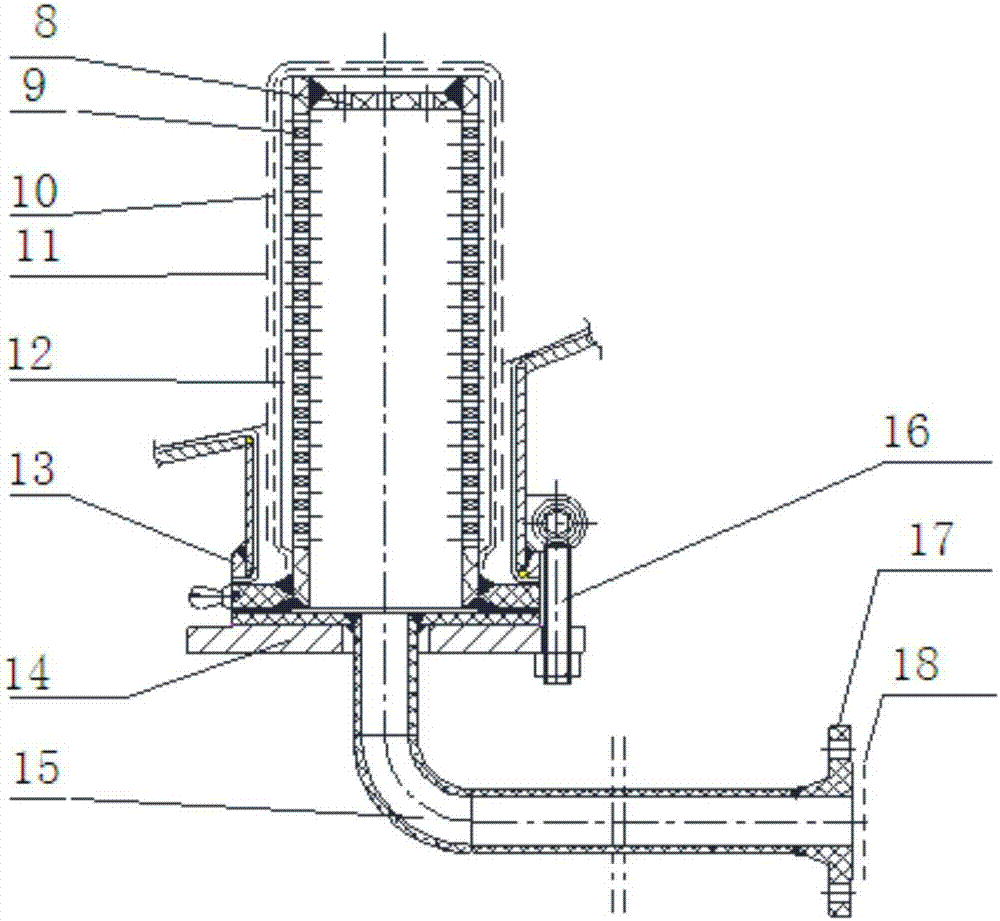

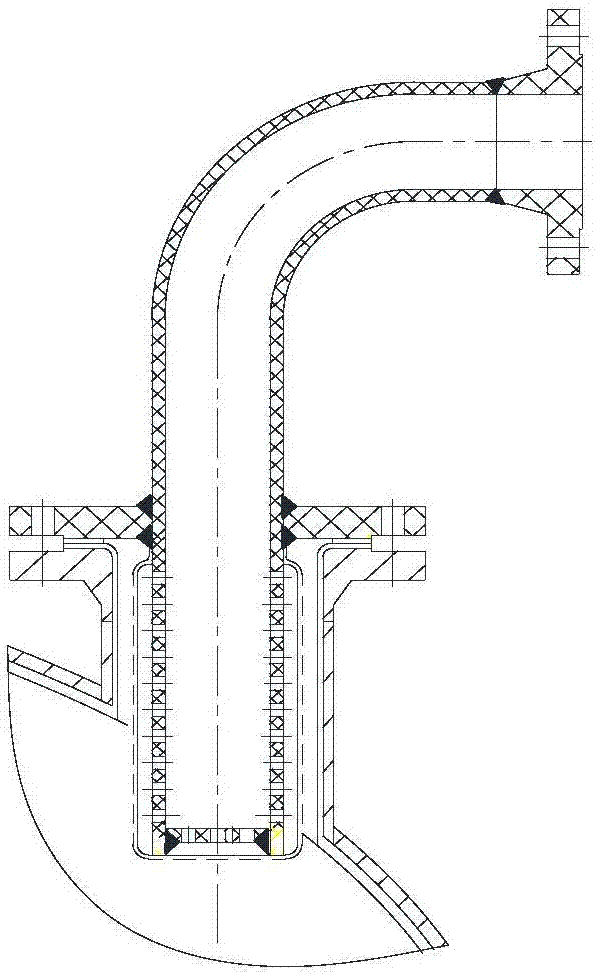

[0021] Such as Figure 1~4 As shown, a dense moving bed ion exchange leaching tower includes an exchange tower 1, a resin inlet port 2, a liquid inlet port 3, an exhaust port 4, a liquid outlet device 5, and a resin outlet port 6, wherein the column type The structure of the exchange tower 1 is provided with a resin inlet 2 and a liquid inlet 3 at the top of the upper head, and an exhaust port 4 is provided near the edge of the upper head; the resin inlet 2 is a detachable flange cylinder structure, It is inserted into the cylinder flange port on the head of the exchange tower 1 and connected and fixed with each other, and the detachable flange cylinder is made of stainless steel detachable parts with good rigidity, vibration resistance, corrosion resistance and wear resistance, which slows down the flow of resin Vibration, impact an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com