Method for extracting rubidium and cesium in salt lake brine

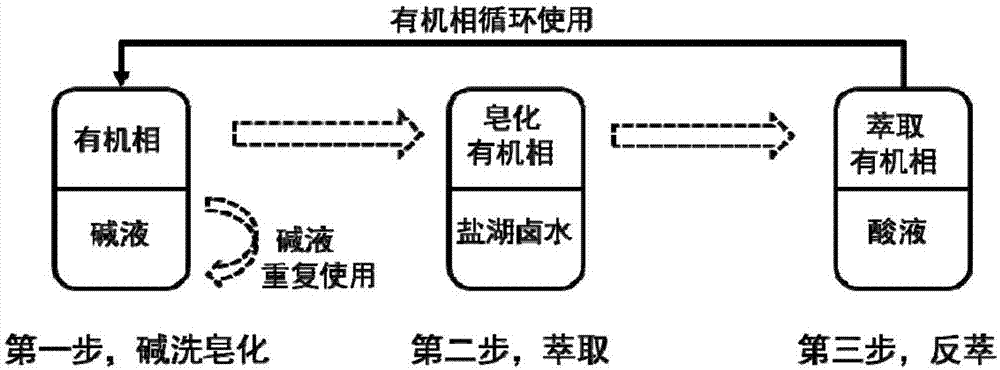

A salt lake brine and extraction technology, applied in the field of hydrometallurgy, can solve the problems of polluting the environment, increasing production and treatment costs, etc., and achieves the effect of small consumption of lye, reduced production costs and treatment costs, and good separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) t-BAMBP and n-hexane are mixed to obtain an organic phase with a t-BAMBP concentration of 0.5mol / L, and the sodium hydroxide solution and the organic phase with a concentration of 0.1mol / L are mixed according to a volume ratio of 1:1, Shake for 1 hour and centrifuge to separate layers to obtain the upper saponified organic phase and the lower lye;

[0044] (2) the organic phase after the saponification that utilizes step (1) to obtain contains 0.005g / L Cs (I), 0.01g / L Rb (I), the saline lake brine of 1g / L K (I) plasma carries out extraction, organic phase and The volume ratio of the salt lake brine is 1:1, and the extraction time is 1 min to obtain an organic extract phase loaded with Cs(I) and Rb(I) in the upper layer and an aqueous raffinate phase in the lower layer;

[0045] (3) back-extract the organic extract phase that step (2) obtains with the sulfuric acid that concentration is 0.1mol / L, the volume ratio of sulfuric acid and organic extract phase 1:1, obtain...

Embodiment 2

[0048] (1) After mixing t-BAMBP and n-heptane to obtain an organic phase with a t-BAMBP concentration of 1.5 mol / L, mix and shake a sodium hydroxide solution with a concentration of 1 mol / L and the organic phase for 5 hours according to a volume ratio of 1:10 After centrifugation and stratification, the organic phase after the saponification of the upper layer and the lye of the lower layer are obtained;

[0049] (2) Utilize the organic phase after the saponification that step (1) obtains to contain 15g / L Cs (I), 20g / L Rb (I), the salt lake brine of 25g / LK (I) plasma is extracted, organic phase and salt lake brine The volume ratio of is 1:10, and the time of extraction is 5min, obtains the organic extract phase that the upper layer is loaded with Cs(I) and Rb(I) and the lower floor water system raffinate phase;

[0050] (3) back-extract the organic extract phase that step (2) obtains with the sulfuric acid that concentration is 0.5mol / L, the volume ratio of sulfuric acid and o...

Embodiment 3

[0053] (1) After mixing t-BAMBP and dodecane to obtain an organic phase with a t-BAMBP concentration of 2mol / L, mix and oscillate a sodium hydroxide solution with a concentration of 1.3mol / L and the organic phase according to a volume ratio of 1:25 Centrifugal layering after 10h, obtain the organic phase after the saponification of the upper layer and the lye of the lower layer;

[0054] (2) Utilize the organic phase after the saponification that step (1) obtains to contain 20g / L Cs (I), 35g / L Rb (I), the salt lake brine of 40g / LK (I) is extracted, the organic phase and salt lake brine The volume ratio is 1:20, and the extraction time is 10min, to obtain an organic extract phase loaded with Cs(I) and Rb(I) in the upper layer and an aqueous raffinate phase in the lower layer;

[0055] (3) the organic extract phase that step (2) obtains is carried out stripping with the nitric acid that concentration is 2mol / L, and the volume ratio of nitric acid and organic extract phase is 1:2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com