Al-Si-Fe-Mg-Cu alloy conductor material and preparation method thereof

A conductor material, al-si-fe-mg-cu technology, is applied in the direction of metal/alloy conductors, conductive materials, conductive materials, etc. It can solve problems such as elastic modulus indicators that are not involved, and achieve improved hardness, low cost, and The effect of increasing the modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

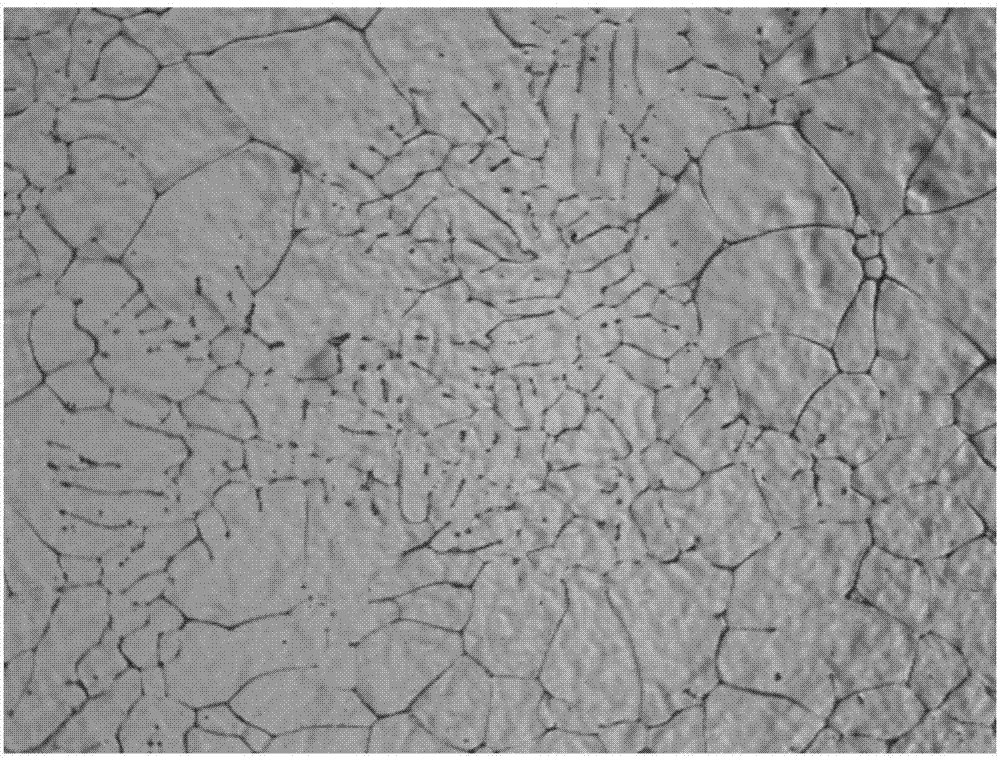

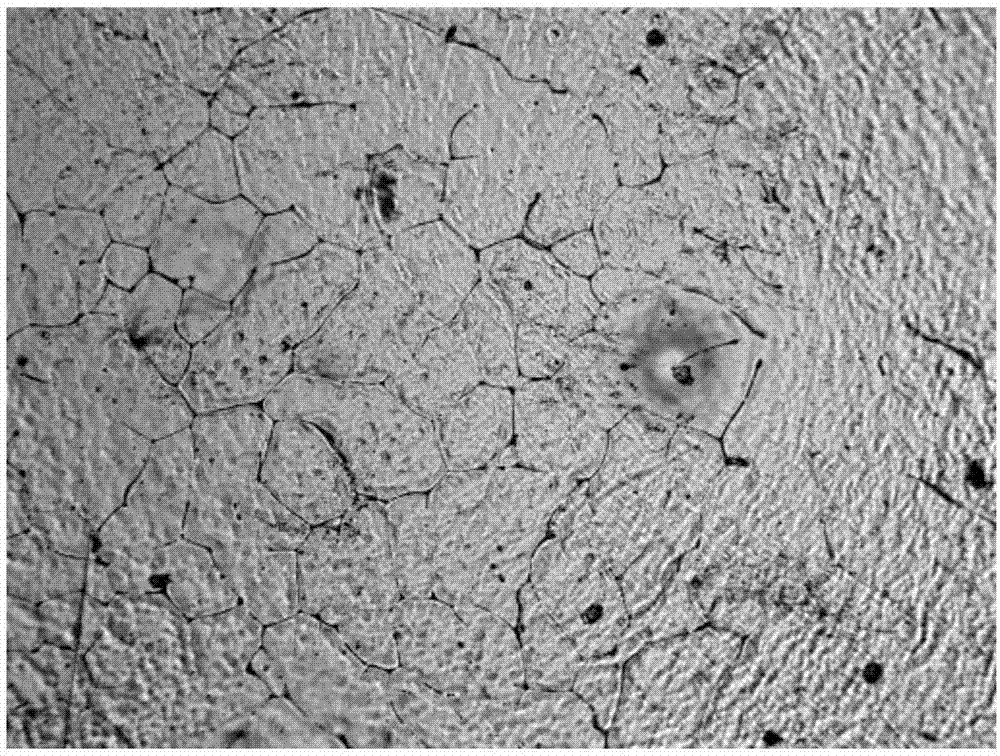

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention are further described below through specific embodiments, which are only for helping to understand the present invention, and should not be regarded as specific limitations to the present invention.

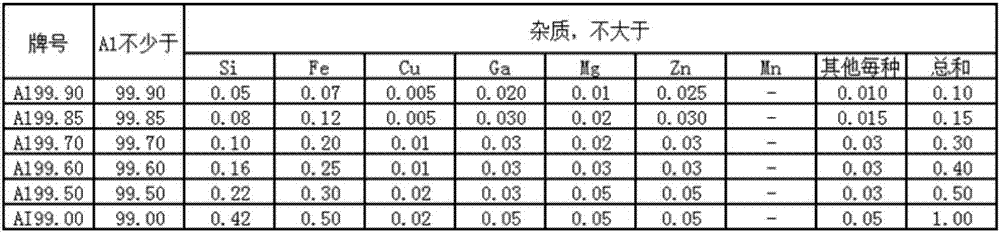

[0040] The composition of Examples 1-10 and Comparative Examples 1-11 is shown in Table 2, wherein Mm is specifically 65% Ce+35% La. Use industrial pure aluminum ingots with a purity of 99.7% (in which Si is 0.05wt%, Fe is 0.13wt%, Cu is 0.01wt%, Mg is 0.01wt%), after melting industrial pure aluminum at 760-780°C, add the alloy Element B, when the content of Fe, Si, Mg, and Cu elements in the industrial pure aluminum ingot is lower than the design content of the corresponding components in Table 2, such as when the content of Fe is lower than the design content of Fe elements described in Table 2 , add the alloy elements, add RE elements, then carry out refining, rapid composition analysis before the furnace, and then adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com