Method for co-producing perfluoro-2-methyl-2-pentene and perfluoro-4-methyl-2-pentene

A technology for methyl and pentene, applied in chemical instruments and methods, preparation of halogenated hydrocarbons, chemical recovery, etc., can solve unfavorable industrial scale-up problems, achieve high conversion rate and selectivity, mild and controllable reaction conditions, and separation The novel effect of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

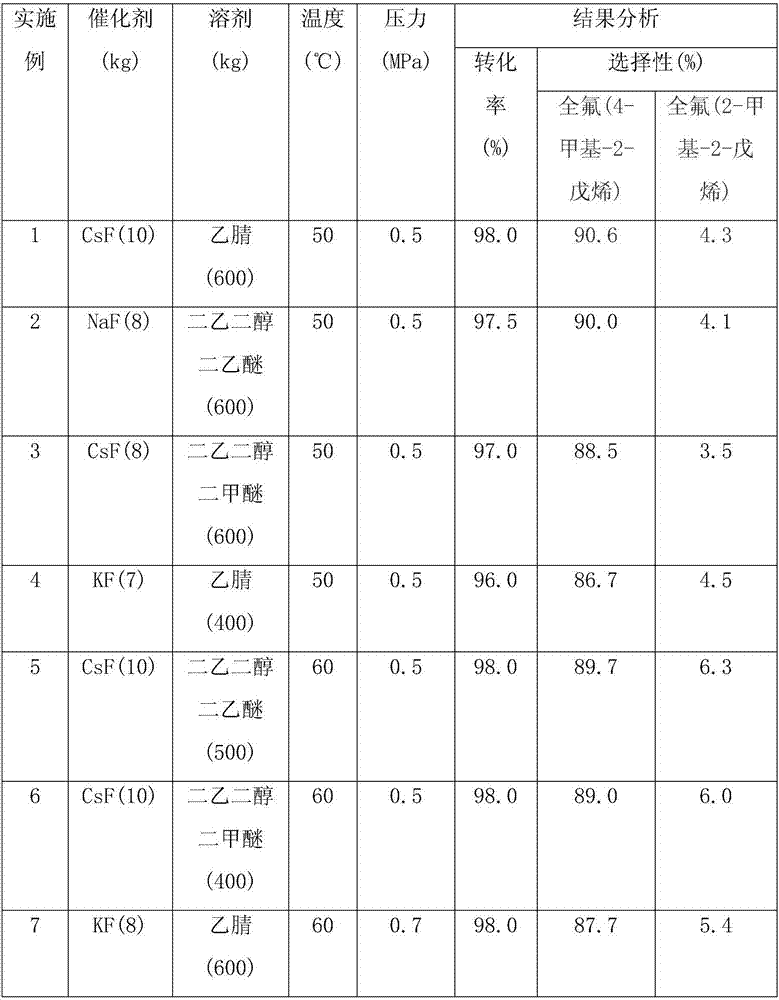

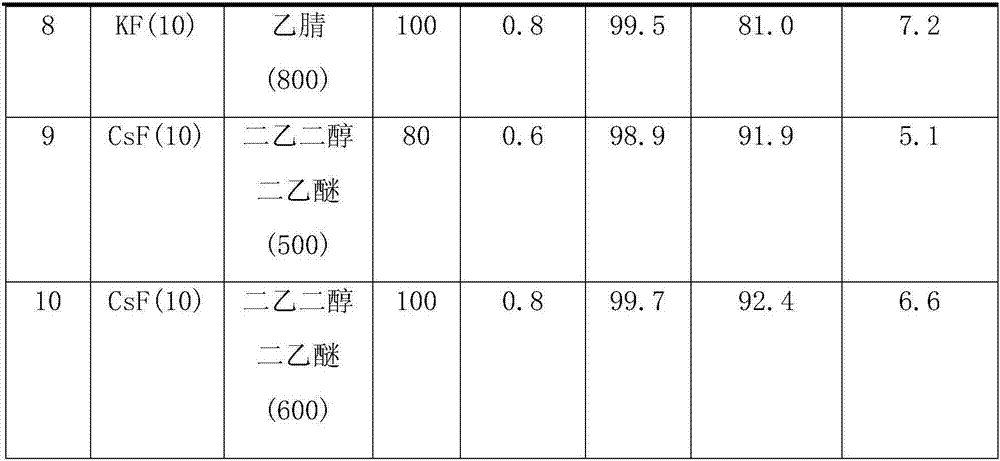

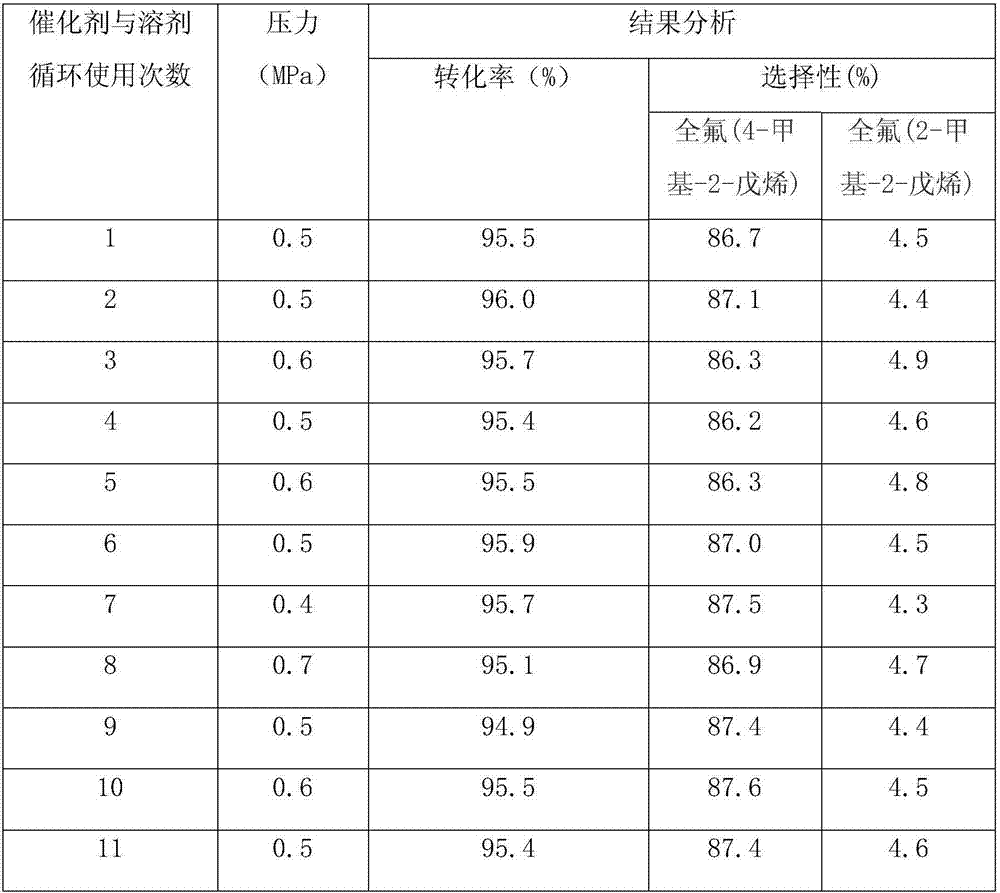

Embodiment 1

[0031] In this example, CsF is used as a catalyst and acetonitrile is used as a solvent to carry out liquid phase oligomerization of hexafluoropropylene to prepare perfluoro-2-methyl-2-pentene and perfluoro-4-methyl-2-pentene.

[0032] Add 600kg of acetonitrile and 10kg of CsF through the feeding port into 2m 3 In the high-pressure reactor, the reactor is then sealed, vacuumed several times, and replaced with nitrogen to make the oxygen content in the reactor less than 20ppm. Then turn on the stirring, raise the temperature to 50° C., continuously and slowly feed 1000 kg of raw material hexafluoropropylene, and control the reaction pressure at about 0.5 MPa. The reaction speed depends on the speed of feeding hexafluoropropylene, and the speed of feeding hexafluoropropylene should not be too fast, otherwise the reaction temperature is difficult to control. After the raw materials are passed through, keep the inner temperature of the reactor at 50°C until the pressure of the re...

Embodiment 2

[0034] In this example, NaF is used as a catalyst and diethylene glycol diethyl ether is used as a solvent to carry out liquid phase oligomerization of hexafluoropropylene to prepare perfluoro-2-methyl-2-pentene and perfluoro-4-methyl-2-pentene .

[0035] Add 600kg of diethylene glycol diethyl ether and 8kg of NaF through the feed port into 2m 3 In the high-pressure reactor, the reactor is then sealed, vacuumed several times, and replaced with nitrogen to make the oxygen content in the reactor less than 20ppm. Then turn on the stirring, raise the temperature to 50° C., continuously and slowly feed 1000 kg of raw material hexafluoropropylene, and control the reaction pressure at about 0.5 MPa. The reaction speed depends on the speed of feeding hexafluoropropylene, and the speed of feeding hexafluoropropylene should not be too fast, otherwise the reaction temperature is difficult to control. After the raw materials are passed through, keep the inner temperature of the reactor ...

Embodiment 3

[0037] In this example, CsF is used as a catalyst and diethylene glycol dimethyl ether is used as a solvent to carry out liquid phase oligomerization of hexafluoropropylene to prepare perfluoro-2-methyl-2-pentene and perfluoro-4-methyl-2-pentene alkene.

[0038] Add 600kg of diethylene glycol dimethyl ether and 8kg of CsF through the feeding port into 2m 3In the high-pressure reactor, the reactor is then sealed, vacuumed several times, and replaced with nitrogen to make the oxygen content in the reactor less than 20ppm. Then turn on the stirring, raise the temperature to 50° C., continuously and slowly feed 1000 kg of raw material hexafluoropropylene, and control the reaction pressure at about 0.5 MPa. The reaction speed depends on the speed of feeding hexafluoropropylene, and the speed of feeding hexafluoropropylene should not be too fast, otherwise the reaction temperature is difficult to control. After the raw materials are passed through, keep the inner temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com