Method and device for detecting accumulated thickness pulse eddy current of fallen oxide skin in austenite boiler tube

A pulsed eddy current and thickness detection technology, used in electromagnetic measurement devices, electric/magnetic thickness measurement, etc., can solve the problems affecting quantitative detection, the transformation of the magnetic properties of the pipe wall, and the electromagnetic interference of detection signals, and achieves good flexibility and use. Convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

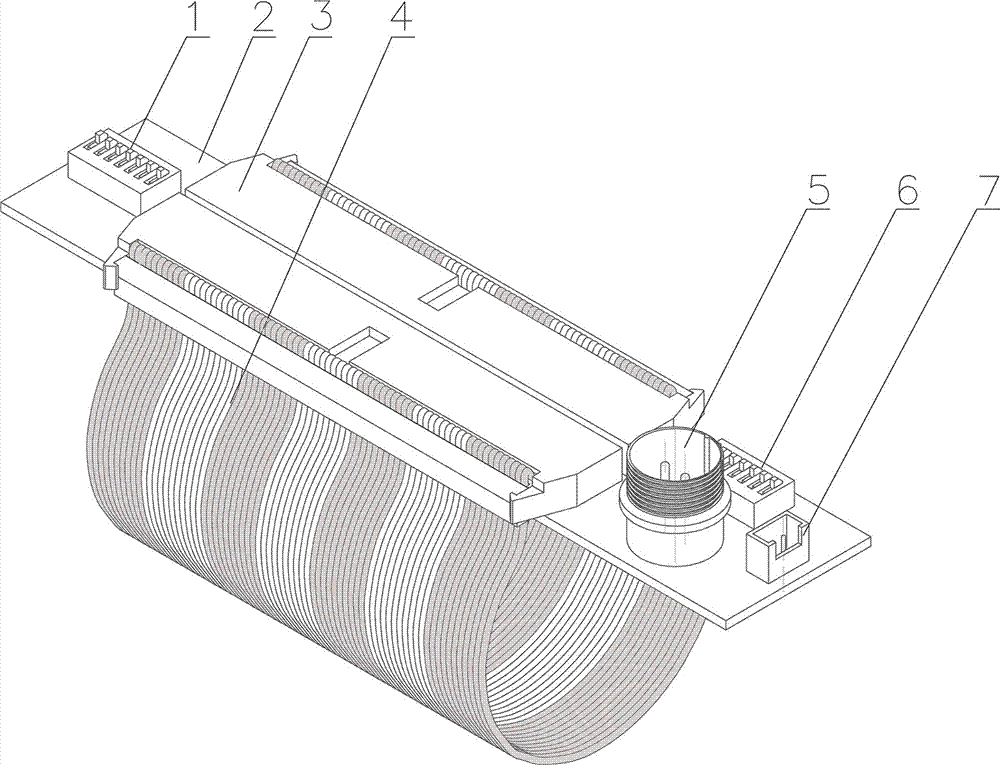

[0046] Embodiment one, see Figure 7 As shown, a pulsed eddy current single sensor is used to detect the average thickness of oxide scale accumulation in the detection area. On the one hand, the installation method of the device includes the following steps:

[0047] Place the connecting socket outside the outer wall of the tube under test in the direction of the axis;

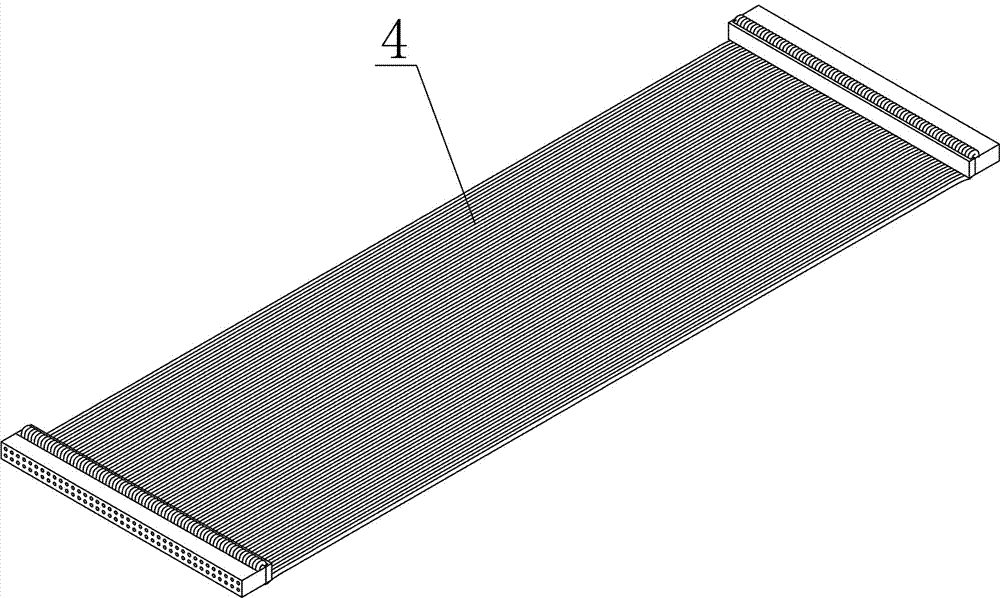

[0048] Select a cable whose length matches the diameter of the pipe, wrap it around the outside of the pipe to be tested, and buckle the two ends of the cable on both sides of the connecting socket to form the excitation unit and the receiving unit;

[0049] Connect the signal input interface with the signal generating source, connect the signal output interface with the signal amplifying device and continue to connect and input it into a computer or other recording equipment.

[0050] On the other hand, its method of use includes the following steps:

[0051] 1. Take the sample tube with the same material a...

Embodiment 2

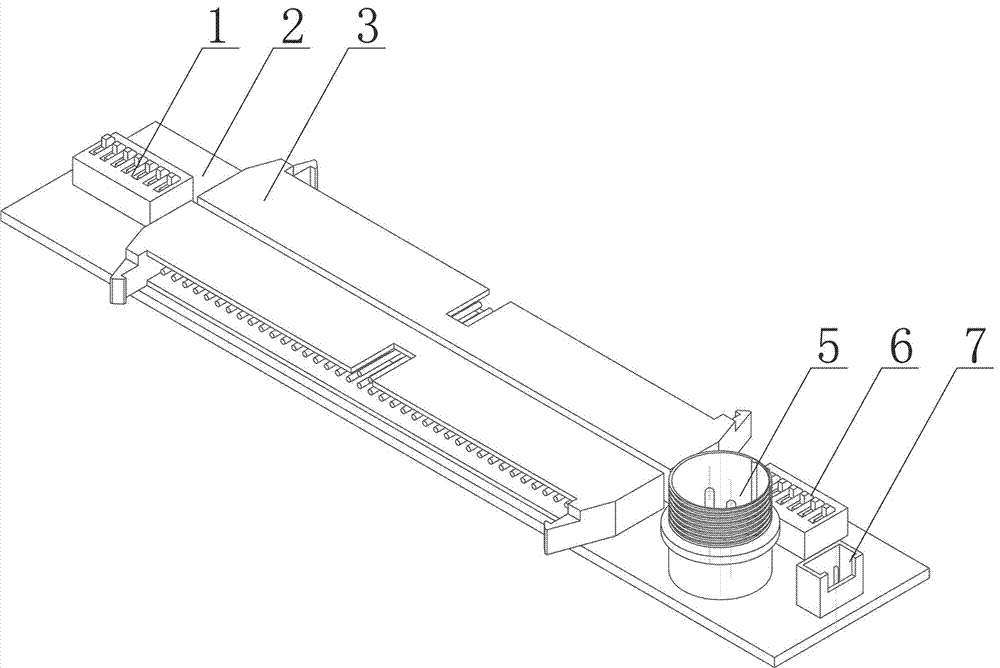

[0060] Embodiment two, see Figure 4 As shown, the pulsed eddy current array sensor is used to detect the oxide scale accumulation thickness and distribution in the detection area. On the one hand, the installation method of the device is the same as that in Embodiment 1. On the other hand, the use method includes the following steps:

[0061] 1. Take the sample tube with the same material and size as the in-service austenitic boiler tube to be tested as the comparison signal collection object;

[0062] 2. Take the excitation and receiving unit (excitation and induction coil) at any position as the reference unit, and turn the corresponding signal input and output switch to the open position, and keep the other position switches off;

[0063] 3. When there is no scale accumulation in the sample tube, the pulse eddy current array sensor ring is mounted on the outer wall of the sample tube, and a pulse excitation signal is applied to the excitation unit. The sample tube inductio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com