Rock-soil mass high volume expansion cement slurry expansion process visualization device and use method

A technology of expansion process and cement slurry, which is applied in the field of visualization device for the expansion process of large-volume expansion cement slurry in rock and soil, can solve the problems of failure mode and evolution law, unfavorable problems, etc., and achieve test cost and cycle saving, simple structure, and materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

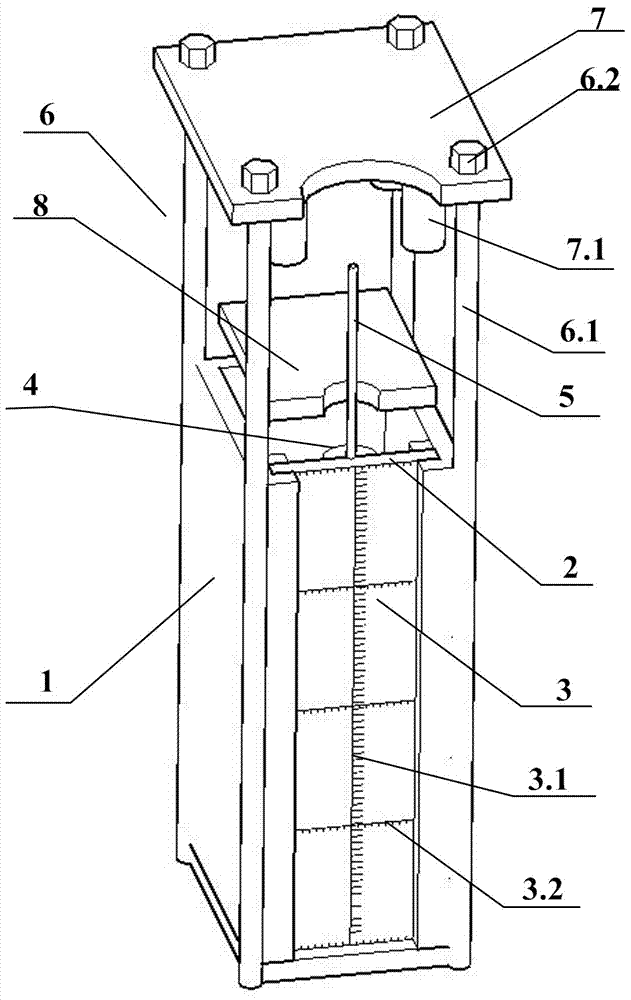

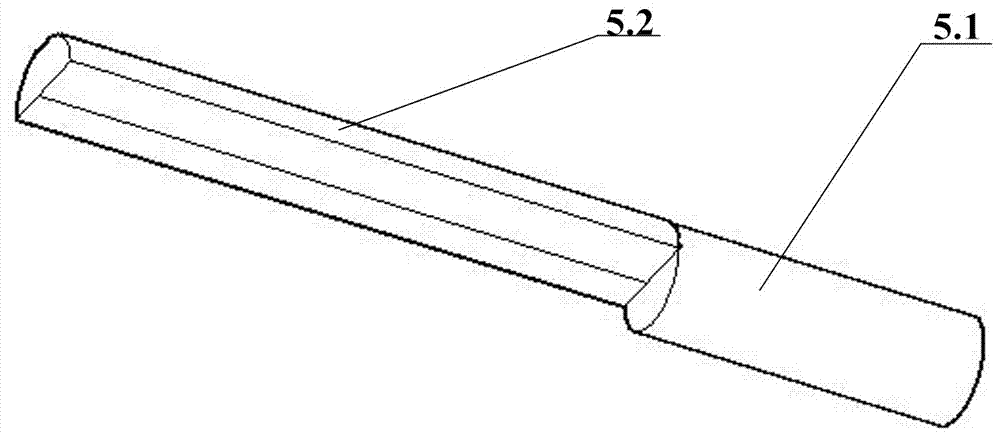

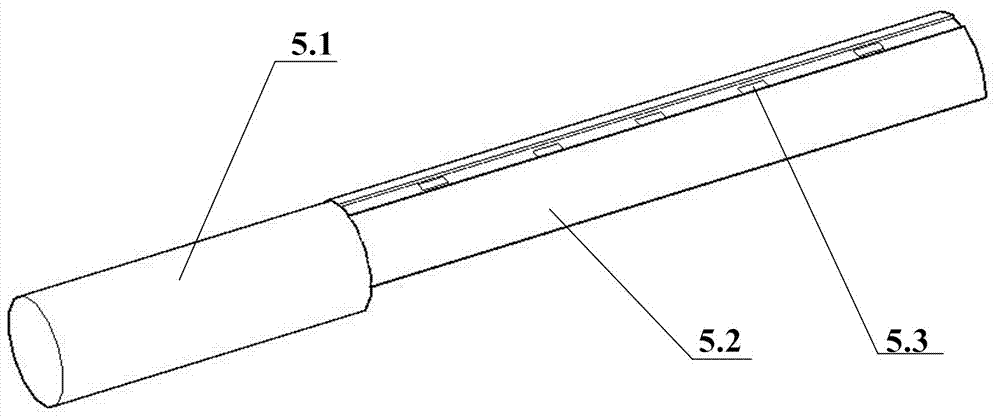

[0049] Step 1): Install tempered glass 2 on one side of cuboid box 1, set scale 3 on the outer surface of tempered glass 2, install pipe 4 on the inner side of tempered glass 2, anchor rod 5 extends into pipe 4, and The pressure sensor on the anchor rod 5 and the output end of the strain gauge are connected with the data acquisition system; the scale 3 of this embodiment includes a vertical scale 3.1 and a horizontal scale 3.2, wherein the vertical scale 3.1 is vertical to the outside of the tempered glass 2 The center line coincides, three horizontal scales 3.2 are arranged horizontally and are perpendicular to the vertical scale 3.1; the pipe material 4 is a semi-circular steel pipe structure, the anchor rod 5 is composed of a cylindrical rod 5.1 and a semi-cylindrical rod 5.2, and the semi-cylindrical rod The outer circular surface of 5.2 is equidistantly provided with grooves 5.3 for installing pressure sensors and strain gauges, the cylindrical rod 5.1 is located on the to...

Embodiment 2

[0056] Step 1): Install tempered glass 2 on one side of cuboid box 1, set scale 3 on the outer surface of tempered glass 2, install pipe 4 on the inner side of tempered glass 2, anchor rod 5 extends into pipe 4, and The pressure sensor on the anchor rod 5 and the output end of the strain gauge are connected with the data acquisition system; the scale 3 of this embodiment includes a vertical scale 3.1 and a horizontal scale 3.2, wherein the vertical scale 3.1 is vertical to the outside of the tempered glass 2 The center line coincides, three horizontal scales 3.2 are arranged horizontally and are perpendicular to the vertical scale 3.1; the pipe material 4 is a semi-circular steel pipe structure, the anchor rod 5 is composed of a cylindrical rod 5.1 and a semi-cylindrical rod 5.2, and the semi-cylindrical rod The outer circular surface of 5.2 is equidistantly provided with grooves 5.3 for installing pressure sensors and strain gauges, the cylindrical rod 5.1 is located on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com