Lithium ion battery graphite anode material and preparation method thereof

A lithium-ion battery, graphite anode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as affecting the coating effect, improve charge-discharge performance and cycle performance, better adaptability, and improve intercalation. The effect of the lithium platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mix ammonia water and absolute ethanol evenly, add artificial graphite, and disperse evenly by ultrasonic;

[0028] (2) Warm up the dispersion liquid obtained in step (1) to 40°C, then add tetrabutyl titanate dropwise, the weight ratio of tetrabutyl titanate and artificial graphite is 15:100, heat and stir for 20 hours;

[0029] (3) The reaction solution in step (2) was cooled to room temperature, centrifuged, and the solid product was dried in an oven, placed in a muffle furnace, and sintered at 500° C. for 2 hours to obtain the lithium ion battery graphite negative electrode material.

Embodiment 2

[0031] (1) Mix ammonia water and absolute ethanol evenly, add artificial graphite, and disperse evenly by ultrasonic;

[0032] (2) Warm up the dispersion obtained in step (1) to 40°C, then add tetrabutyl titanate dropwise, the weight ratio between tetrabutyl titanate and artificial graphite is 5:100, and heat and stir for 20 hours;

[0033] (3) The reaction solution in step (2) was cooled to room temperature, centrifuged, and the solid product was dried in an oven, placed in a muffle furnace, and sintered at 500° C. for 3 hours to obtain the lithium ion battery graphite negative electrode material.

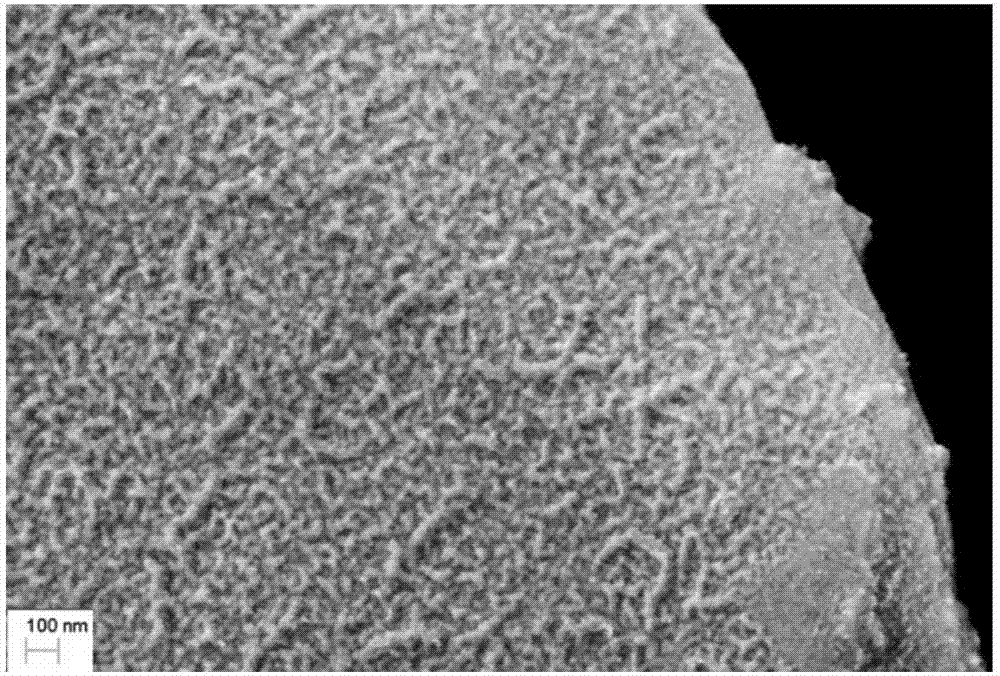

[0034] figure 1 It is an electron microscope image of the lithium-ion battery graphite negative electrode material obtained in this example. It can be seen that the original smooth graphite surface is modified with a layer of titanium dioxide.

[0035] In order to test the performance of the lithium ion battery negative electrode material prepared by the present invention, with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com