Integrated device for dredging drainage pipeline based on high pressure rotating jet flow

A drainage pipeline and high-pressure technology, applied in the field of drainage pipeline dredging equipment, can solve the problems of waste of water resources, high risk and easy occurrence of poisoning, and achieve the effects of saving water resources, improving dredging efficiency and good dredging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

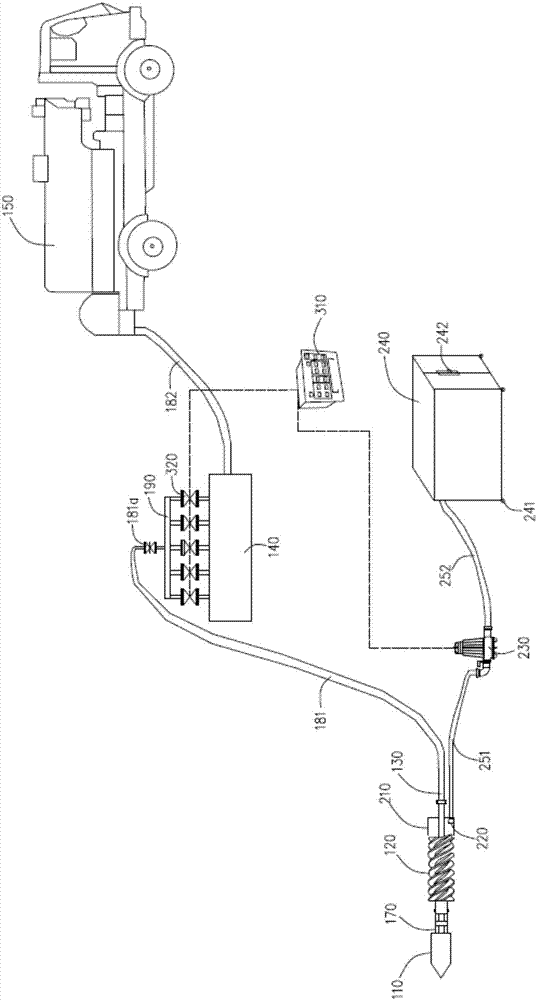

[0027] Referring to the accompanying drawings, the figure shows an integrated drainage pipe dredging device based on high-pressure rotary jet, including a flushing component, a dredging component and a control component.

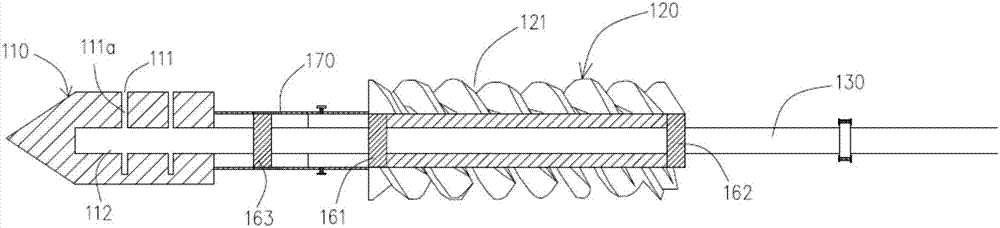

[0028] The flushing assembly includes a high-pressure nozzle 110 , a helical sleeve rod 120 , a hollow steel pipe 130 , a pressurized gas tank 140 and a dredging vehicle 150 .

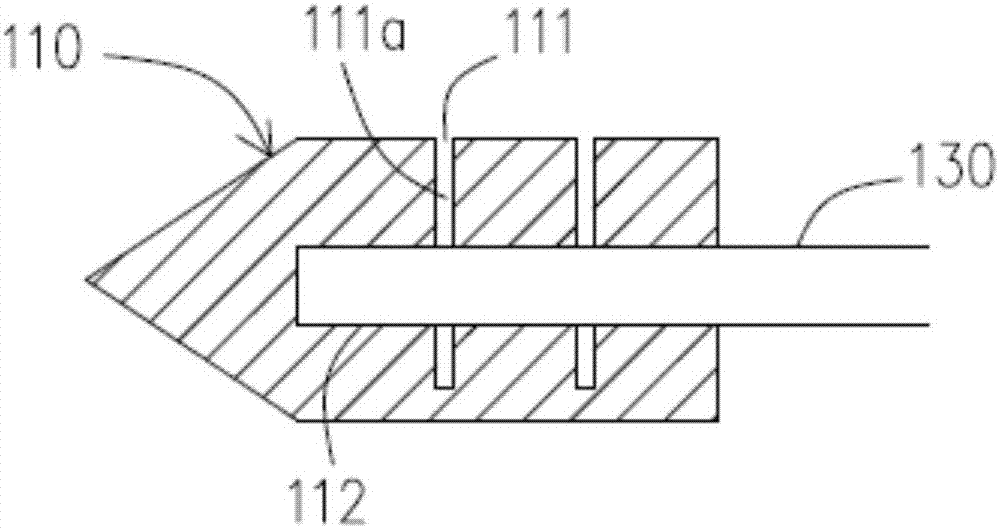

[0029] The high-pressure nozzle 110 is axially arranged on the first end of the hollow steel pipe 130 and its water inlet end is connected to the first port 131 of the hollow steel pipe 130 . The outer surface of the high-pressure nozzle 110 is provided with several spray holes 111 at intervals in the upper direction. In this embodiment, the front part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com