Solid electrolyte membrane and preparation method thereof

A solid electrolyte membrane and solid electrolyte layer technology, applied in solid electrolyte, electrolyte battery manufacturing, non-aqueous electrolyte and other directions, can solve the problems of high electrode contact interface resistance, brittle and hard mechanical properties, poor processing, and other problems, and achieve high electrical conductivity. efficiency, good flexibility, and low interfacial resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The embodiment of the present application also discloses a method for preparing a solid electrolyte membrane, including steps:

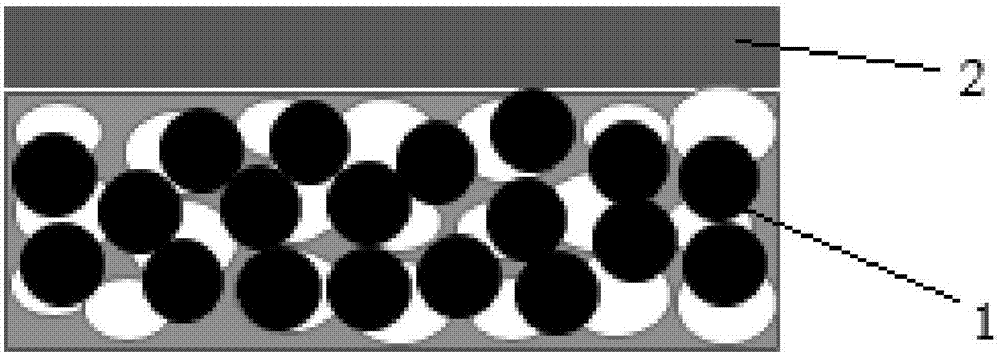

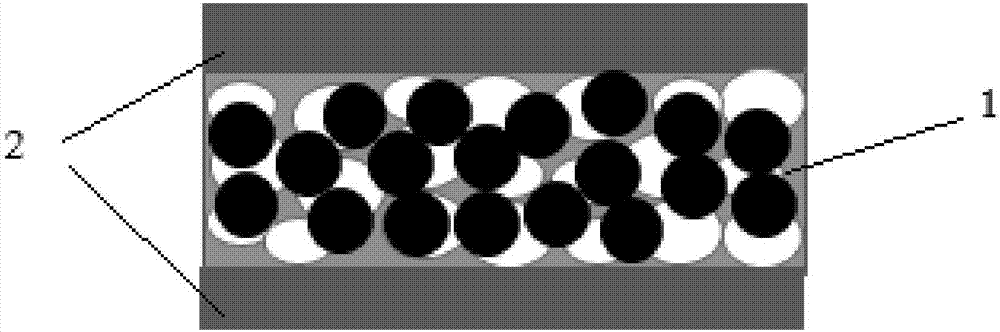

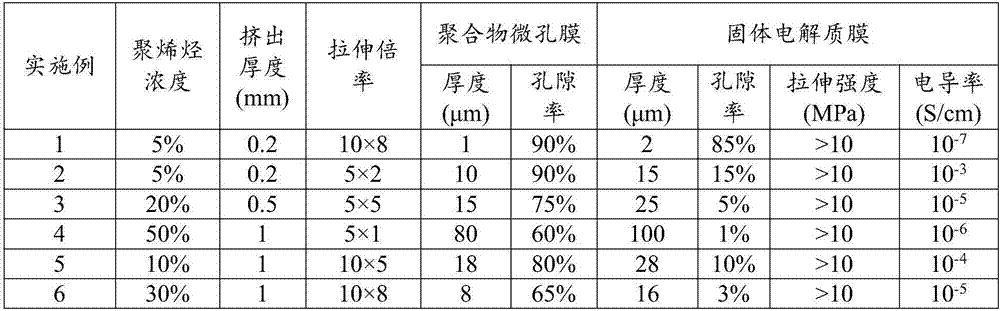

[0035] (1), using a phase separation method to prepare a polymer matrix with a continuous three-dimensional network structure with a thickness of 1-100 microns, a diameter of 0.02-5 microns, and a porosity of 60-90%;

[0036] (2) The polymer matrix is soaked in a slurry containing solid electrolyte powder, pulled out and dried to obtain a solid electrolyte layer with a thickness of 2-100 microns and a porosity of 0.1-15%;

[0037] (3) The surface of the solid electrolyte layer is coated with a composite layer to obtain a solid electrolyte membrane.

[0038] In the step (1), the phase separation method includes a thermally induced phase separation method and a solvent induced phase separation method.

[0039] In the step (3), a composite layer is coated on the surface of the solid electrolyte layer by means of transfer coating.

[0040] The...

Embodiment 7

[0049] (1) Preparation of polyvinylidene fluoride-hexafluoropropylene microporous membrane by phase separation method: the molecular weight is 4×10 5 The polymer polyvinylidene fluoride-hexafluoropropylene was dissolved in N,N-dimethylformamide (DMF) at room temperature to obtain a solution with a polyethylene concentration of 10 wt%, and cast into a 200 μm film, and the film Immediately immerse in a water bath at 20°C to cool, dry at 80°C to remove the solvent, and biaxially stretch at 160°C with a stretching ratio of 10*5 to obtain a polymer with a thickness of 5 microns, a wire diameter of 0.02 to 5 microns, and a porosity of 90%. Fluoroethylene-hexafluoropropylene microporous membrane.

[0050] (2), soak the polymer microporous membrane with high porosity in the Li with a size of 1 μm 1.5 al 0.5 Ge 1.5 (PO 4 ) 3 (LAGP) The slurry of solid electrolyte powder was pulled out and dried to obtain a solid electrolyte layer with a thickness of 15 microns and a porosity of 20...

Embodiment 8

[0053] (1) Preparation of polyacrylonitrile microporous membrane by phase separation method: the molecular weight is 3x10 5 The polymer polyacrylonitrile is dissolved in N,N-dimethylformamide (DMF) at room temperature to obtain a solution with a concentration of polyacrylonitrile of 10 wt%, immediately immersed in a 20°C water bath to cool, and dried at 80°C to remove Solvent, biaxial stretching at 180°C, the stretching ratio is 10*8, and a polyacrylonitrile microporous membrane with a thickness of 8 microns, a wire diameter of 0.02-5 microns and a porosity of 90% is obtained.

[0054] (2), soak the polymer microporous membrane with high porosity in the Li with a size of 1 μm 1.5 al 0.5 Ge 1.5 (PO 4 ) 3 (LAGP) The slurry of solid electrolyte powder was pulled out and dried to obtain a solid electrolyte layer with a thickness of 15 microns and a porosity of 20%.

[0055] (3), by the method for transfer coating, composite layer is coated on the single side of solid electrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com