Preparation method of bacteriostatic and wound restoration promoting chitosan hydrogel dressing

A technology of wound repair and chitosan, which is applied in the application field of biomedical materials, can solve the problems of general antibacterial performance and reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

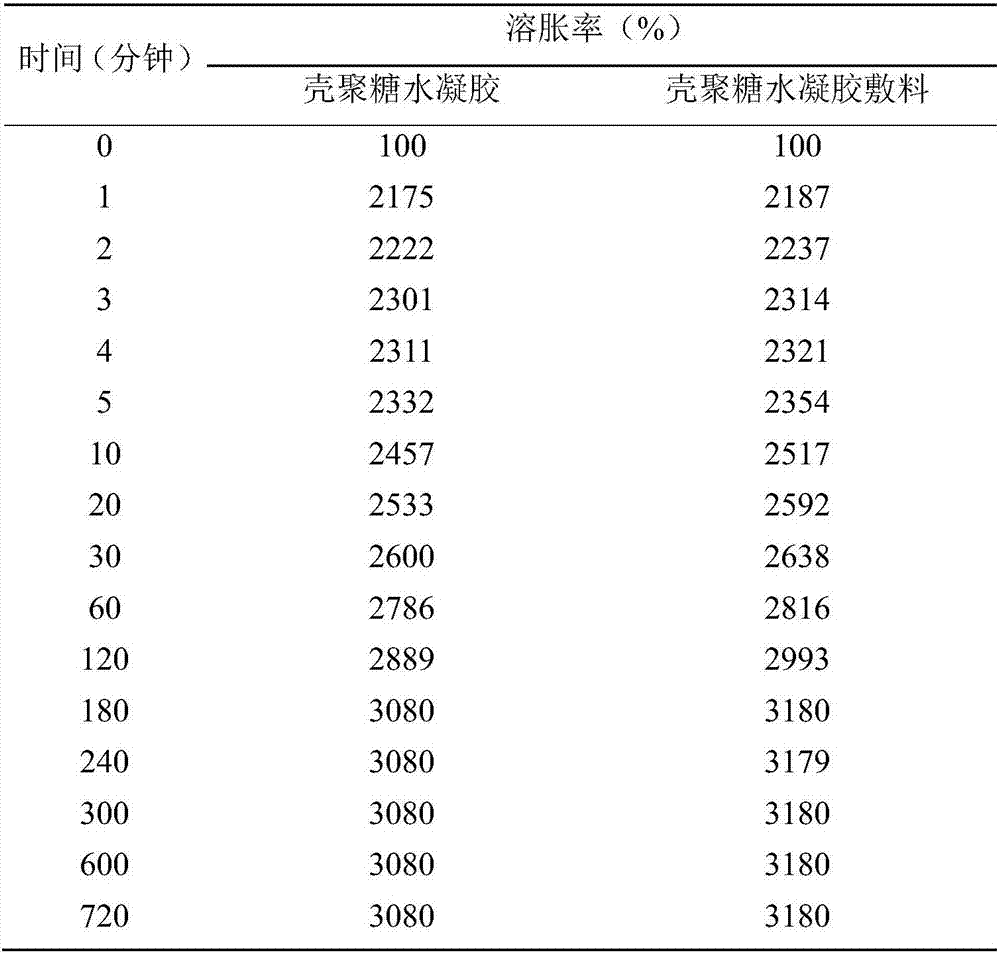

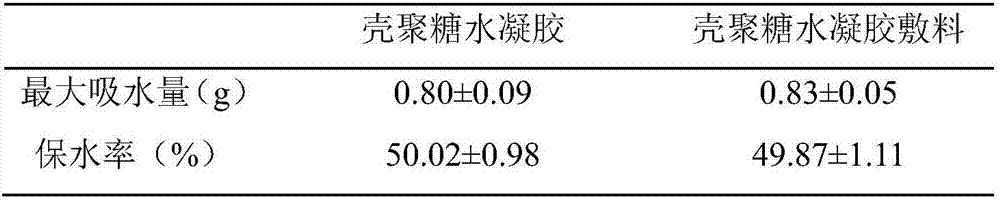

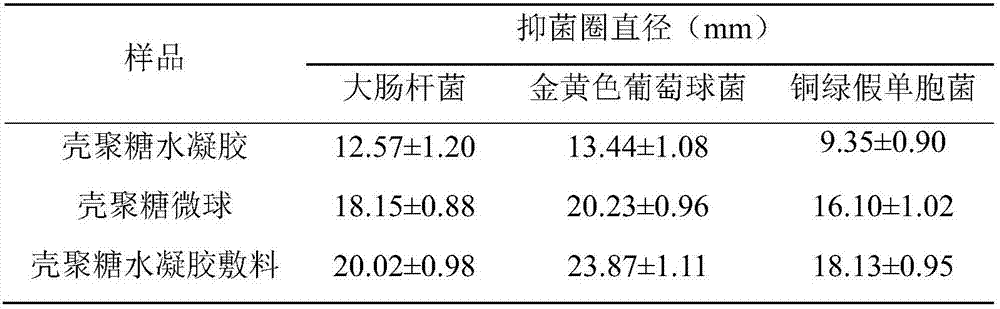

[0015] First, 2.5 g of molecular weight 1 × 10 5 Da, chitosan with a degree of deacetylation of 70% is dissolved in 250mL of 1% (v / v) acetic acid aqueous solution, and then 125mL of 1,2-dichloroethane and 0.94g of cellulose acetate are added at 35°C Stir at 1000rpm for 1 hour to emulsify under the conditions, add 12.5mL glutaraldehyde with a volume ratio concentration of 1% (v / v) and continue stirring for 1 hour to fix the microspheres, then use 387.5mL saturated sodium chloride solution to break the emulsion, centrifuge, Wash to obtain chitosan microspheres; 20mg chitosan microspheres are uniformly dispersed in 250mL mass volume ratio concentration of chitosan aqueous solution of 1% (w / v), at 20 ℃ with 12.5mL volume ratio concentration 1% (v / v) glutaraldehyde cross-linked for 1 hour, then soaked in deionized water to wash off excess cross-linking agent, and removed 10% of water in an oven to obtain a chitosan hydrogel dressing.

Embodiment 2

[0017] First, 3 g of molecular weight 1 × 10 4 Da, the chitosan that deacetylation degree is 85% is dissolved in 250mL volume ratio concentration and is the acetic acid aqueous solution of 1% (v / v), then adds 150mL ethyl acetate and 5g cellulose acetate butyrate, under 45 ℃ of conditions Stir at 750rpm for 1.5 hours to emulsify, add 25mL glutaraldehyde with a volume ratio concentration of 1% (v / v) and continue stirring for 1.5 hours to fix the microspheres, then use 820mL saturated sodium chloride solution to break the emulsion, centrifuge and wash to obtain chitosan Sugar microspheres; 15mg chitosan microspheres are uniformly dispersed in 250mL mass volume ratio concentration of chitosan aqueous solution of 2% (w / v), at 15 ℃ with 37.5mL volume ratio concentration of 1% (v / v) glutaraldehyde cross-linked for 2 hours, then soaked with deionized water, washed off excess cross-linking agent, and removed 20% of moisture in an oven to obtain a chitosan hydrogel dressing.

Embodiment 3

[0019] First, 5g of molecular weight is 3×10 5 Da, chitosan with a deacetylation degree of 99% is dissolved in 250mL volume ratio concentration of 3% (v / v) acetic acid aqueous solution, then 250mL cyclohexanone and 12.5g cellulose acetate propionate are added, at 40°C Stir at 1000rpm for 1 hour to emulsify, add 37.5mL of glutaraldehyde with a volume ratio concentration of 1% (v / v) and continue to stir for 2 hours to fix the microspheres, then use 1000mL saturated sodium chloride solution to break the emulsion, centrifuge and wash to obtain Chitosan microspheres: 10mg chitosan microspheres are uniformly dispersed in 250mL mass volume ratio concentration of 4% (w / v) chitosan aqueous solution, and 12.5mL volume ratio concentration is 1% under the condition of 30 ℃. (v / v) glutaraldehyde was cross-linked for 2 hours, then soaked with deionized water to wash away excess cross-linking agent, and removed 15% of moisture in an oven to obtain a chitosan hydrogel dressing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com