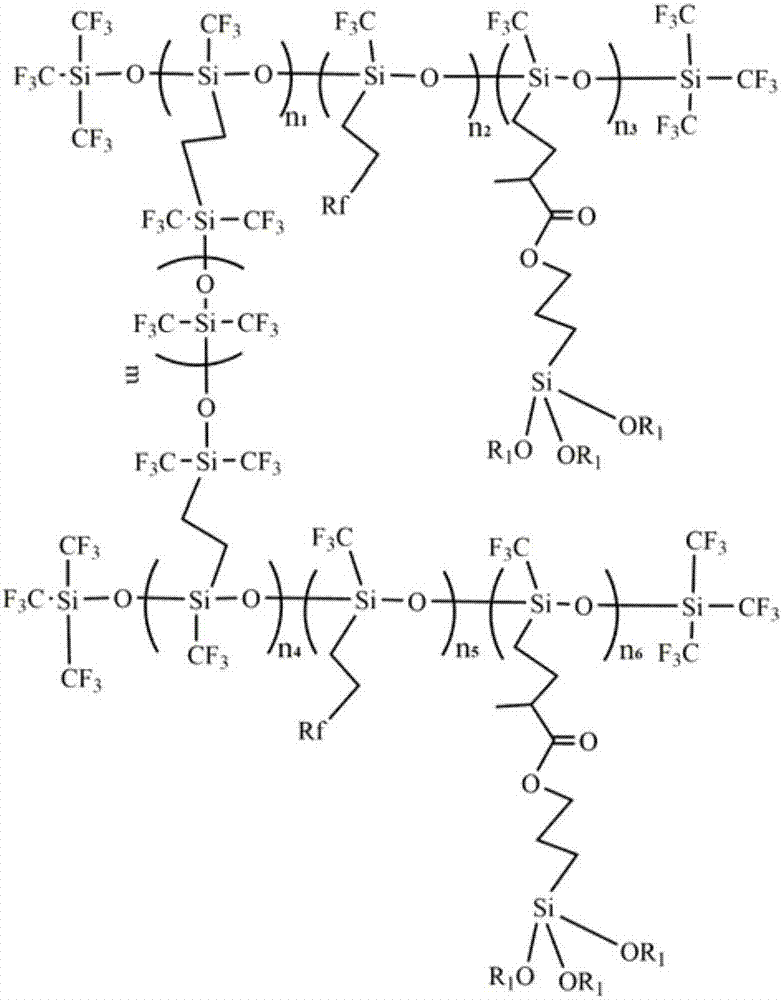

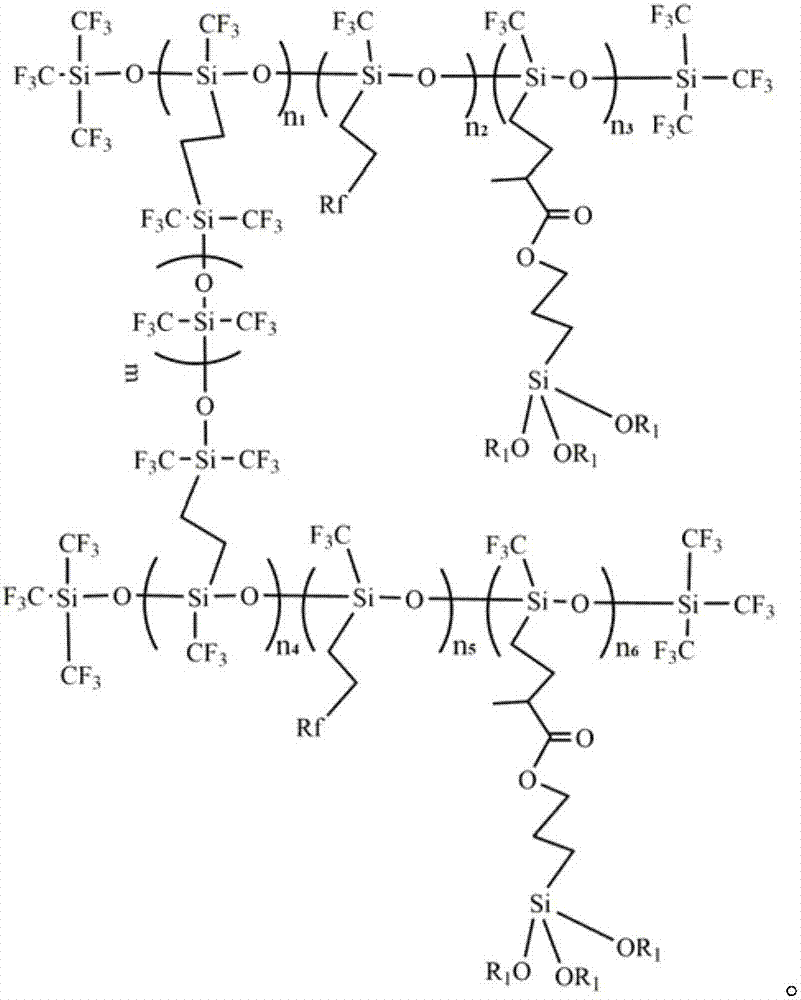

Room-temperature curing super-hydrophobic self-cleaning fluorosilicone resin and preparation method thereof

A technology of fluorosilicone resin and room temperature curing, which is applied in the direction of coating, etc., and can solve the problems of complex coating forming methods and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

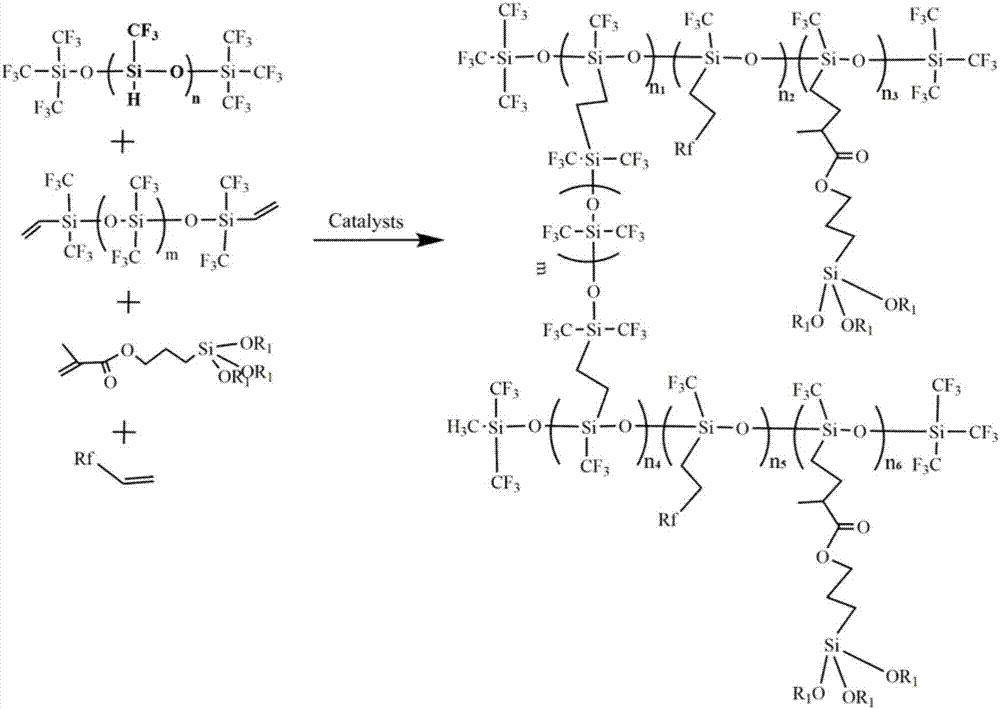

Method used

Image

Examples

Embodiment 1

[0022] The room temperature curing superhydrophobic self-cleaning fluorosilicone resin of the present invention has a specific preparation method as follows:

[0023] First, 60 parts of perfluorinated hydrogen-containing polymethylhydrogensiloxane (hydrogen content is 0.8, viscosity 100mPa·s), 4 parts of methacrylic acid-2,2,3,4,4,4-hexafluorobutyl Ester, 10 parts of perfluoro-terminated vinyl polysiloxane (viscosity 200mPa·s), 300 parts of n-heptane were added to the reactor and stirred evenly, heated to 60°C, and then 1.5 parts of Karsted catalyst solution with a concentration of 400ppm were added , react at 60°C for 4 hours, then dropwise add 5 parts of γ-methacryloxypropyltriethoxysilane dropwise, and finish adding dropwise in 1 hour; cool to normal temperature and continue stirring for 2 hours to obtain the Superhydrophobic self-cleaning fluorosilicone.

Embodiment 2

[0025] The room temperature curing superhydrophobic self-cleaning fluorosilicone resin of the present invention has a specific preparation method as follows:

[0026] First, 60 parts of perfluorinated hydrogen-containing polymethylhydrogensiloxane (hydrogen content is 1.6, viscosity 30mPa·s), 6 parts of allyl pentafluorobenzene, 5 parts of perfluoro-terminated vinyl polysiloxane (viscosity 100mPa·s), 300 parts of petroleum ether (boiling range 90-120), add to the reactor and stir evenly, heat to 80°C, then add 0.5 parts of Karsted catalyst solution with a concentration of 100ppm, react at 80°C for 3.5 hours, and then Add 8 parts of γ-methacryloxypropyltrimethoxysilane dropwise, and the dropwise addition is completed within 1 hour; cool to room temperature and continue stirring for 1.5 hours to obtain the superhydrophobic self-cleaning fluorosilicone resin of the present invention.

Embodiment 3

[0028] The room temperature curing superhydrophobic self-cleaning fluorosilicone resin of the present invention has a specific preparation method as follows:

[0029] First, 60 parts of perfluorinated hydrogen-containing polymethylhydrogen siloxane (hydrogen content is 1.2, viscosity 50mPa·s), 8 parts of methacrylic acid-3,3,4,4,5,5,6,6, Add 7,7,8,8,8-tridecafluorooctyl ester, 5 parts of perfluorovinyl polysiloxane (viscosity: 600mPa·s), and 400 parts of cyclohexane into the reactor, stir evenly, and heat to 75°C, then add 1.0 parts of Karsted catalyst solution with a concentration of 300ppm, react at 75°C for 2.5 hours, then add 3 parts of γ-methacryloxypropyl tripropropoxysilane dropwise, dropwise for 1h; cool Continue to stir for 1 hour at room temperature to obtain the superhydrophobic self-cleaning fluorosilicone resin of the present invention.

[0030] Apply the superhydrophobic self-cleaning fluorosilicone resin in the example to the glass surface, about 2g / cm 2 , the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com