Method for manufacturing carburization bearing steel for high speed train

A technology of high-speed EMUs and manufacturing methods, which is applied in the field of metal material manufacturing, and can solve problems such as unsatisfactory requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Both Example 1 and Example 2 adopt the production process: vacuum induction furnace smelting→casting electrodes→electrode annealing→vacuum consumable furnace remelting→steel ingot annealing→steel ingot forging→bar annealing.

[0040] 1. Production process

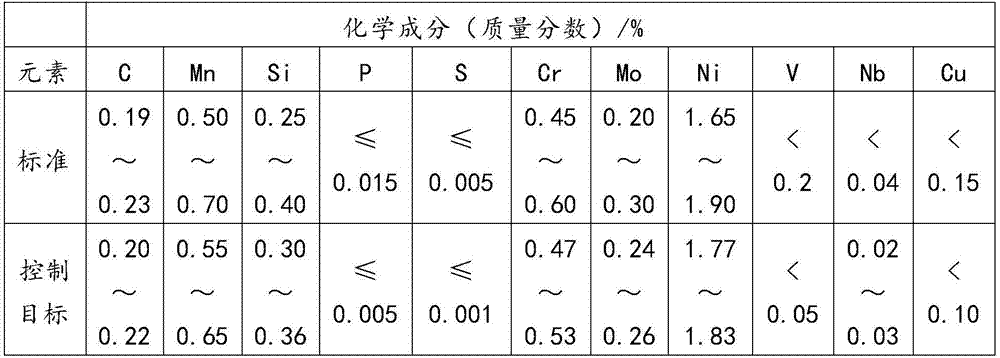

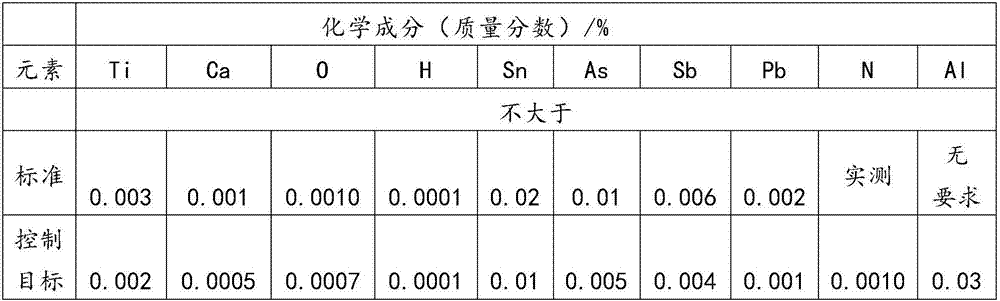

[0041] (1) Vacuum induction furnace smelting: Industrial pure iron and pure metal materials that meet the requirements are used. The element content of industrial pure iron is 0.18% carbon, 0.20% silicon, 0.001% sulfur, 0.003% phosphorus, and 0.002% titanium. Calcium is 0.0002%; pure metal materials such as silicon, manganese, chromium, nickel and molybdenum are oil-free and rust-free on the surface.

[0042] ① Melting period: Industrial pure silicon, metal chromium, metal nickel, metal molybdenum and industrial pure iron are added in batches during the melting period and electro-melted, leaving a small part of pure metal residue and all metal manganese for subsequent seasoning.

[0043] (3) After the electrode is d...

Embodiment 2

[0063] 1. Production process

[0064] ⑴ Vacuum induction furnace smelting: ② Refining period: the vacuum degree of the smelting chamber is pumped to 3Pa, and the refining temperature of the molten steel is kept at 1560°C. After the holding time is 120min, the other elements except manganese are seasoned and the control target requirements are met; throughout the refining During the process, add carbon powder 2 times and stir several times.

[0065] (2) Pouring period: According to the requirements of the control target, after adding metal manganese and adjusting the temperature of the molten steel to 1578°C, the electrode is poured, and the electrode specification is Φ580mm.

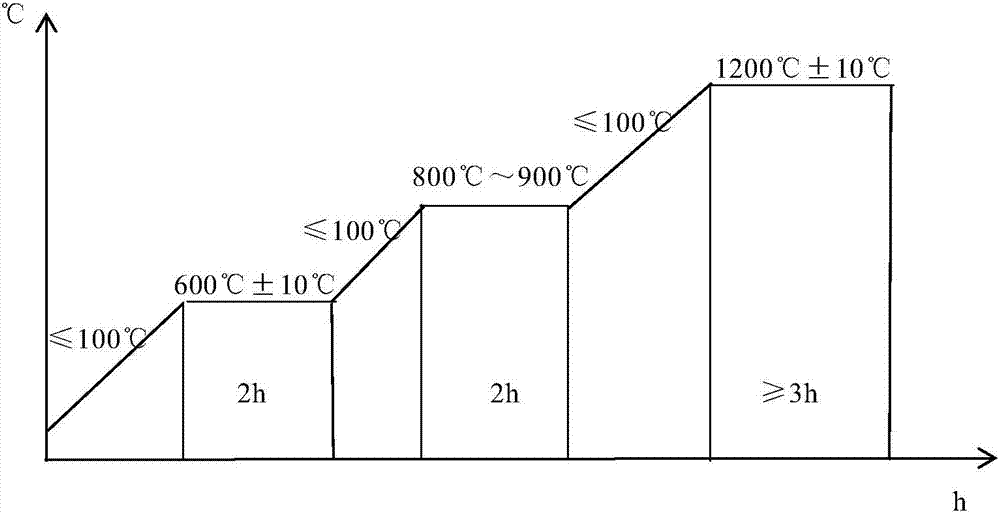

[0066] ⑹ Forging process: The steel ingot is heated in the heating furnace at 100°C / h to 600°C for 2 hours, and then the temperature is raised at 100°C / h. When the temperature reaches 850°C, the heat preservation is started. h rises to 1200°C for 3 hours; start forging, the first fire forges the steel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com