Glass partition in refrigerator

A glass and partition technology, applied in glass tempering, glass manufacturing equipment, applications, etc., can solve the problems of insufficient glass strength, poor load-bearing capacity, easy to break or deform, and achieve good dimensional stability, simple preparation method, The effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

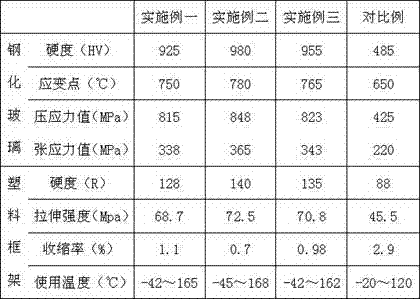

Examples

Embodiment 1

[0017] A glass partition in a refrigerator proposed by the present invention is jointly formed by tempered glass and a plastic frame. The tempered glass includes raw materials in the following weight percentages: 1.8% of tempering agent, and the balance is glass. The plastic frame includes the following weight: Parts of raw materials: 50 parts of polycarbonate, 38 parts of polystyrene, 13 parts of polyoxymethylene, 15 parts of epoxy soybean oil, 26 parts of calcium carbonate powder, 7 parts of additives, wherein the toughening agent is a mass ratio of 6:10: 8:9:15 mixture of potassium oxide, silicon carbide, aluminum oxide, aluminum oxide and sodium carbonate, additives include plasticizer, heat stabilizer, antifungal agent, adhesive and curing agent.

[0018] Its preparation method comprises the following steps:

[0019] S1. Add the tempering agent in the weight percentage to the grinder, and grind it thoroughly to obtain a fine powder with a particle size of 1mm;

[0020] S...

Embodiment 2

[0024] A glass partition in a refrigerator proposed by the present invention is jointly formed by tempered glass and a plastic frame. The tempered glass includes raw materials in the following weight percentages: 1.5% of tempering agent, and the balance is glass. The plastic frame includes the following weight: Parts of raw materials: 40 parts of polycarbonate, 32 parts of polystyrene, 10 parts of polyoxymethylene, 12 parts of epoxy soybean oil, 22 parts of calcium carbonate powder, 5 parts of additives, wherein the toughening agent is a mass ratio of 4:5: 7:6:12 mixture of potassium oxide, silicon carbide, aluminum oxide, aluminum oxide and sodium carbonate, additives include plasticizer, heat stabilizer, antifungal agent, adhesive and curing agent.

[0025] Its preparation method comprises the following steps:

[0026] S1. Add the tempering agent in the weight percentage to the grinder, and grind it thoroughly to obtain a fine powder with a particle size of 0.5mm;

[0027] ...

Embodiment 3

[0031] A glass partition in a refrigerator proposed by the present invention is jointly formed by tempered glass and a plastic frame, and the tempered glass includes raw materials in the following weight percentages: 1.2% of tempering agent, and the balance is glass, and the plastic frame includes the following weight: Parts of raw materials: 30 parts of polycarbonate, 25 parts of polystyrene, 6 parts of polyoxymethylene, 9 parts of epoxy soybean oil, 18 parts of calcium carbonate powder, 3 parts of auxiliary agent, wherein the tempering agent is a mass ratio of 2:1: 5:4:10 mixture of potassium oxide, silicon carbide, alumina, aluminum oxide and sodium carbonate, additives include plasticizer, heat stabilizer, antifungal agent, adhesive and curing agent.

[0032] Its preparation method comprises the following steps:

[0033] S1. Add the tempering agent in the weight percentage to the grinder, and grind it thoroughly to obtain a fine powder with a particle size of 0.05 mm;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com